Head suspension

A magnetic head and suspension technology, applied in the direction of supporting head, configuration/installation of recording head, structure of arm parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

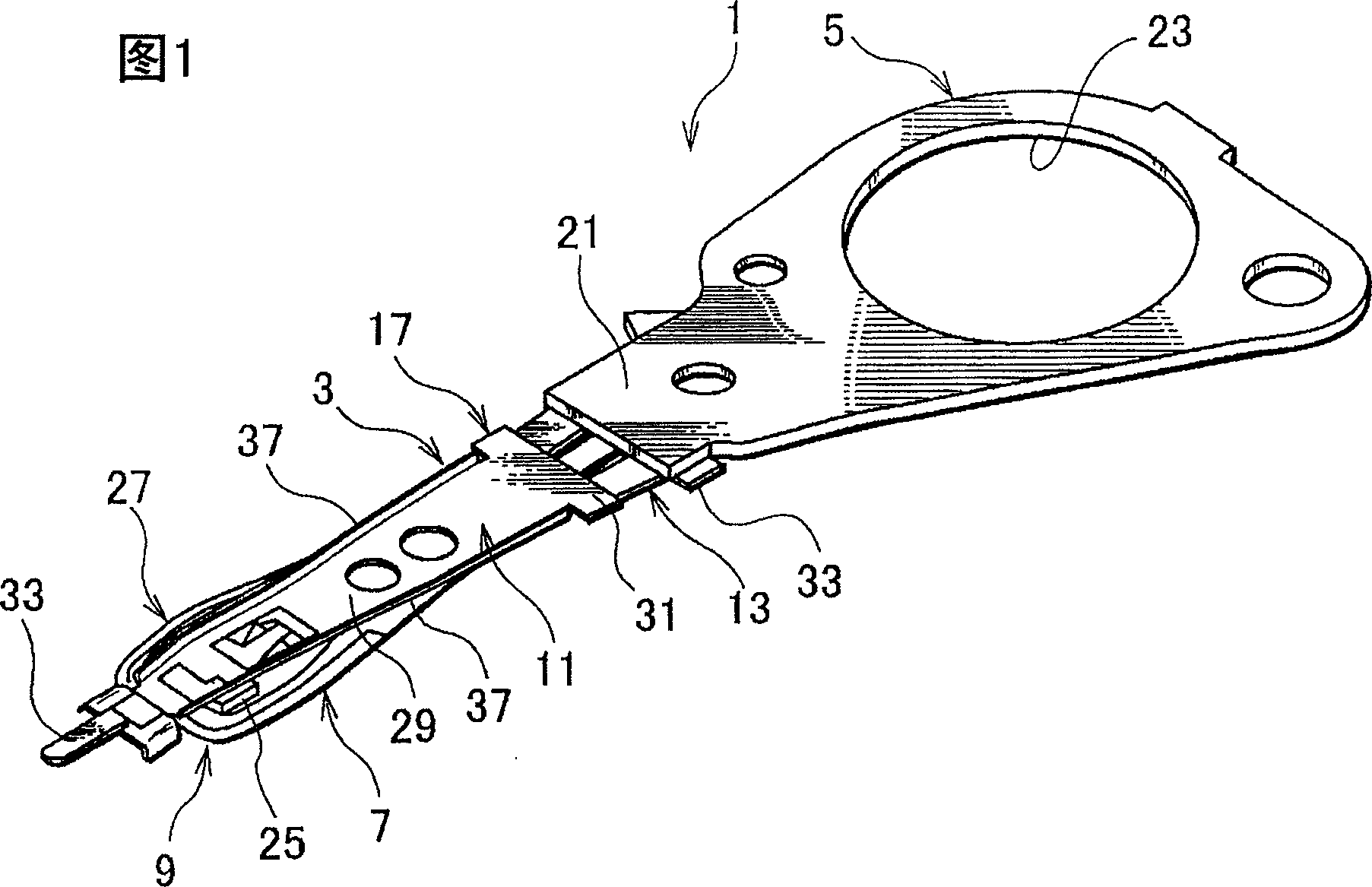

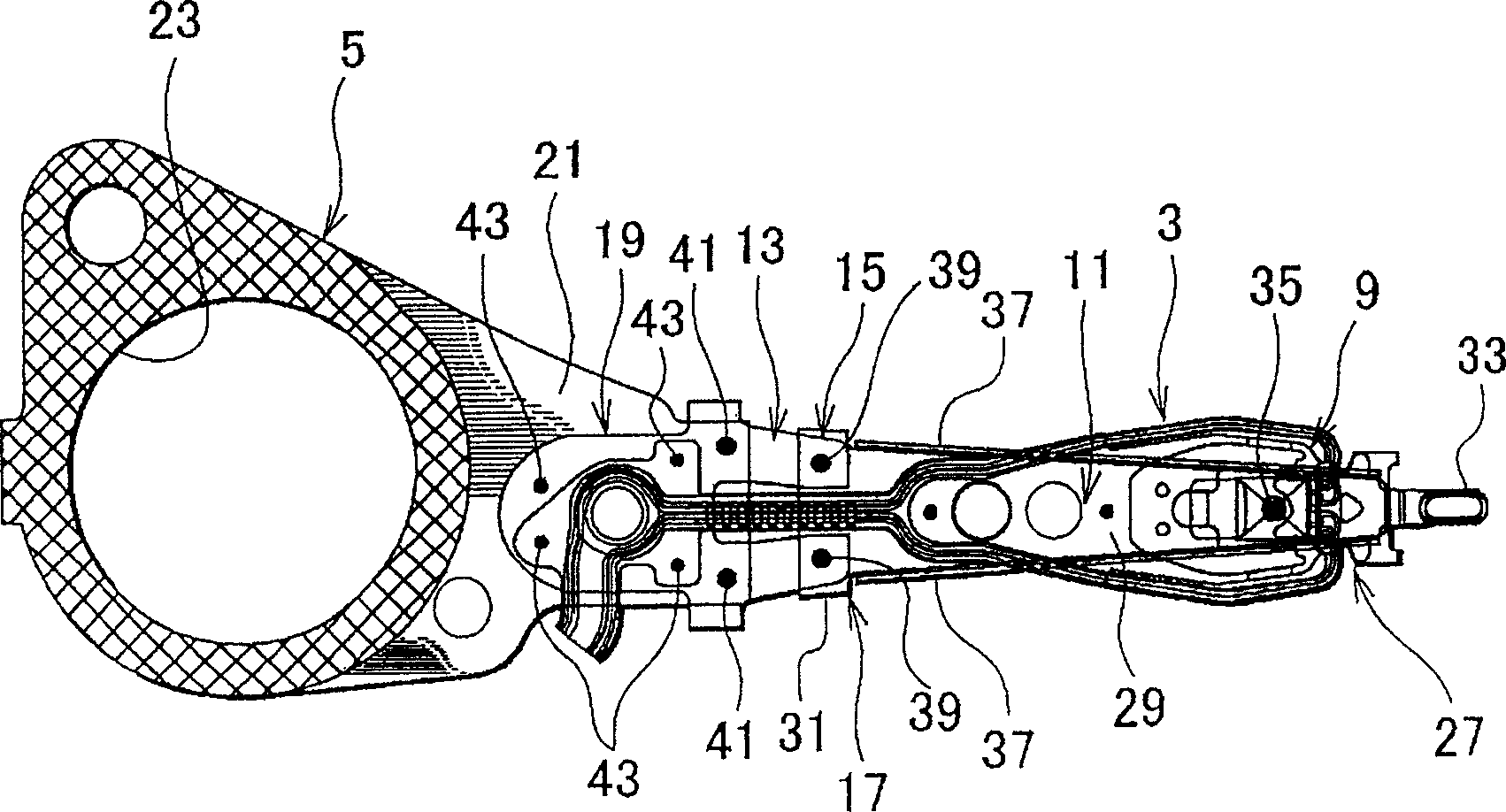

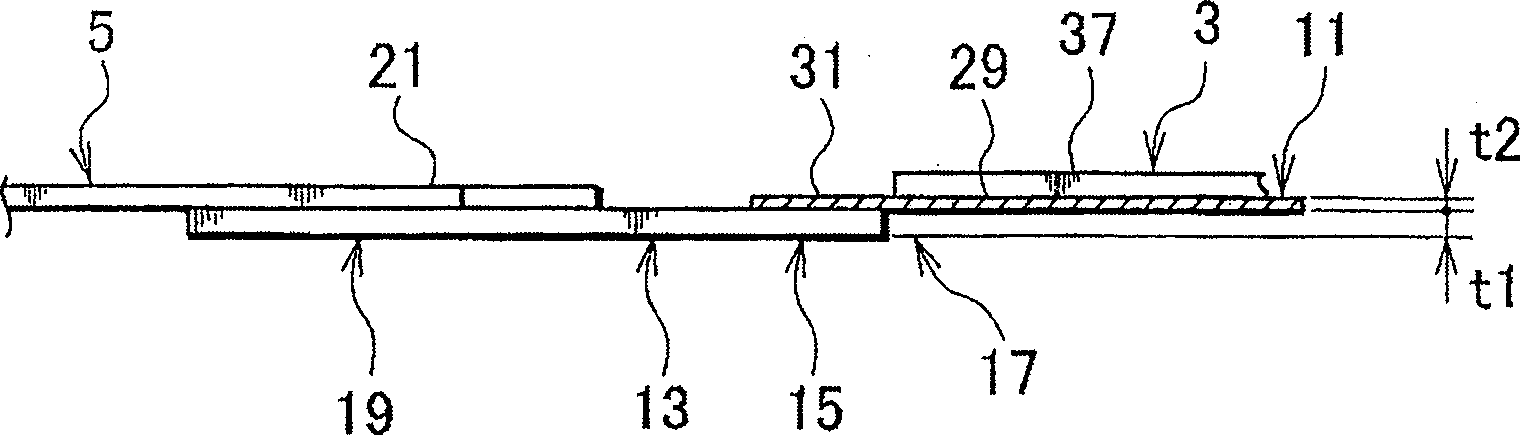

[0047] Figure 1 and figure 2 Showing a head suspension according to a first embodiment of the present invention, FIG. 1 is a perspective view, figure 2 is a top view.

[0048] The head suspension 1 shown in Figs. 1 and 2 is for a 1-inch size, for example. The head suspension has a load beam 3 , an arm 5 and a flexure 7 .

[0049] The load beam 3 applies a load to the magnetic head 9 . The magnetic head 9 is arranged at the front end of the load beam 3 to read data from the magnetic disk and write data to the magnetic disk. The load beam 3 includes a beam 11 serving as a rigid member and a hinge 13 serving as an elastic member.

[0050] The hinge 13 is prepared to be separated from the beam 11 . The first end 15 of the hinge 13 is fixed and supported on the base end 17 of the beam 11 , and the second end 19 of the hinge 13 is fixed and supported on the arm 5 .

[0051] The arm 5 comprises an integrated base plate 21 serving as a base for supporting the second end 19 of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com