Apparatus and method of separating and purifying water solution of phenol, catechol, hydroquinone and tar

A hydroquinone and aqueous solution technology, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve problems such as difficult transportation and separation, easy carbonization or puffing, and poor fluidity, so as to ensure high purity And the effects of high yield, low risk of material heat sensitivity, and low concentration of phenolic water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

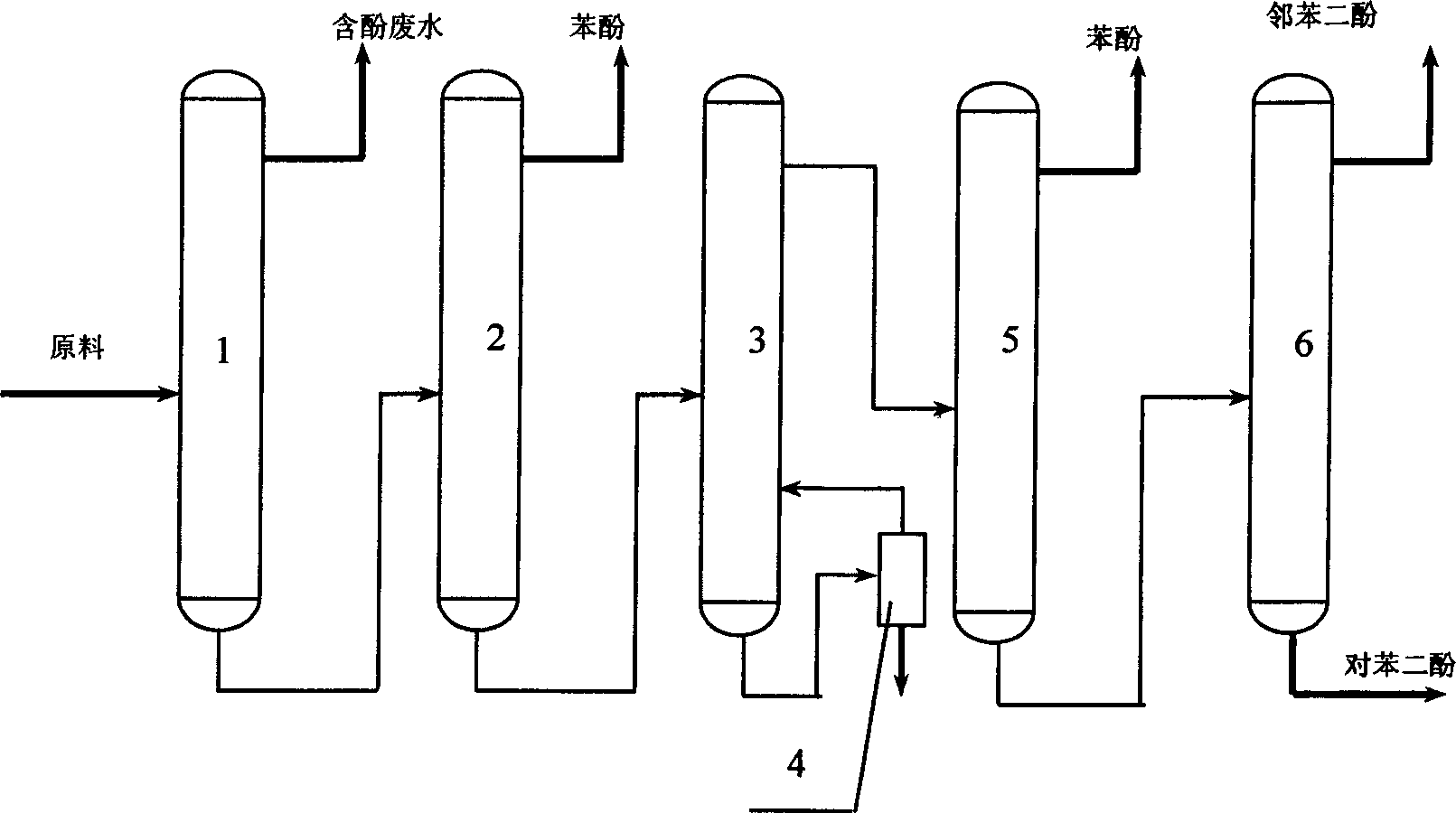

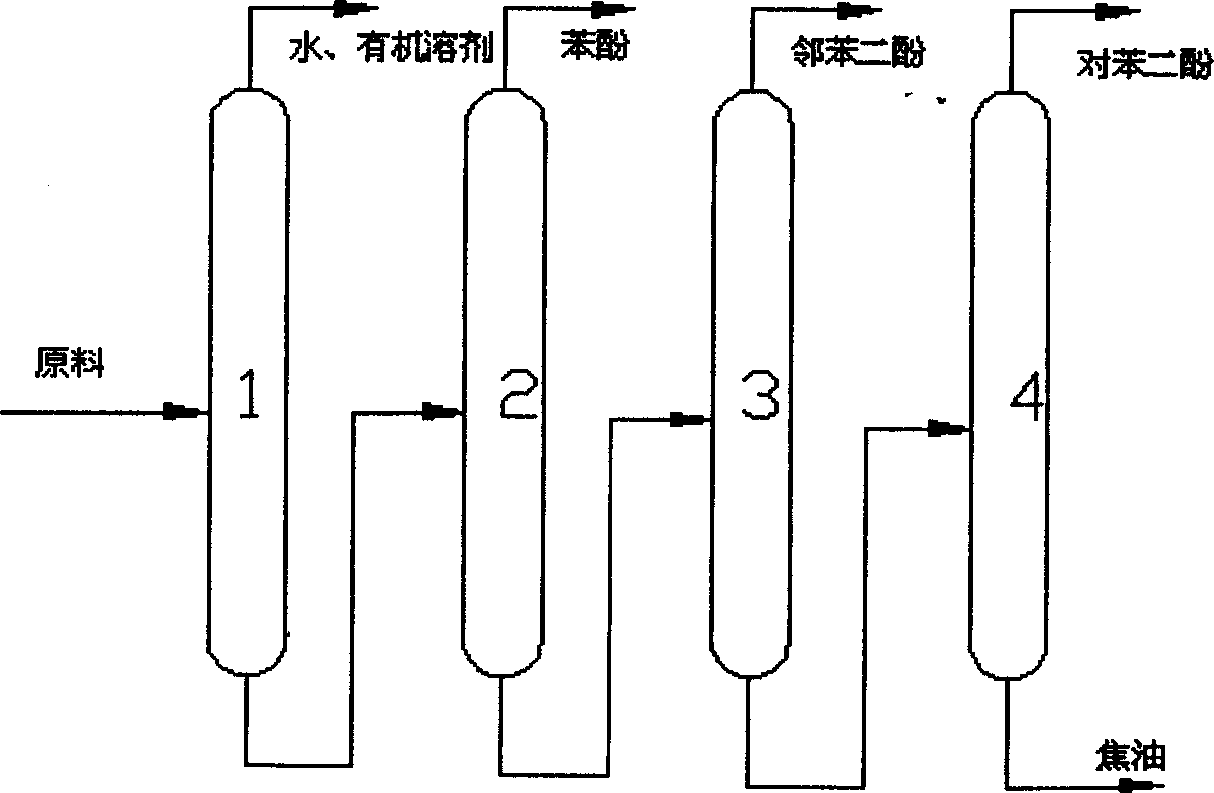

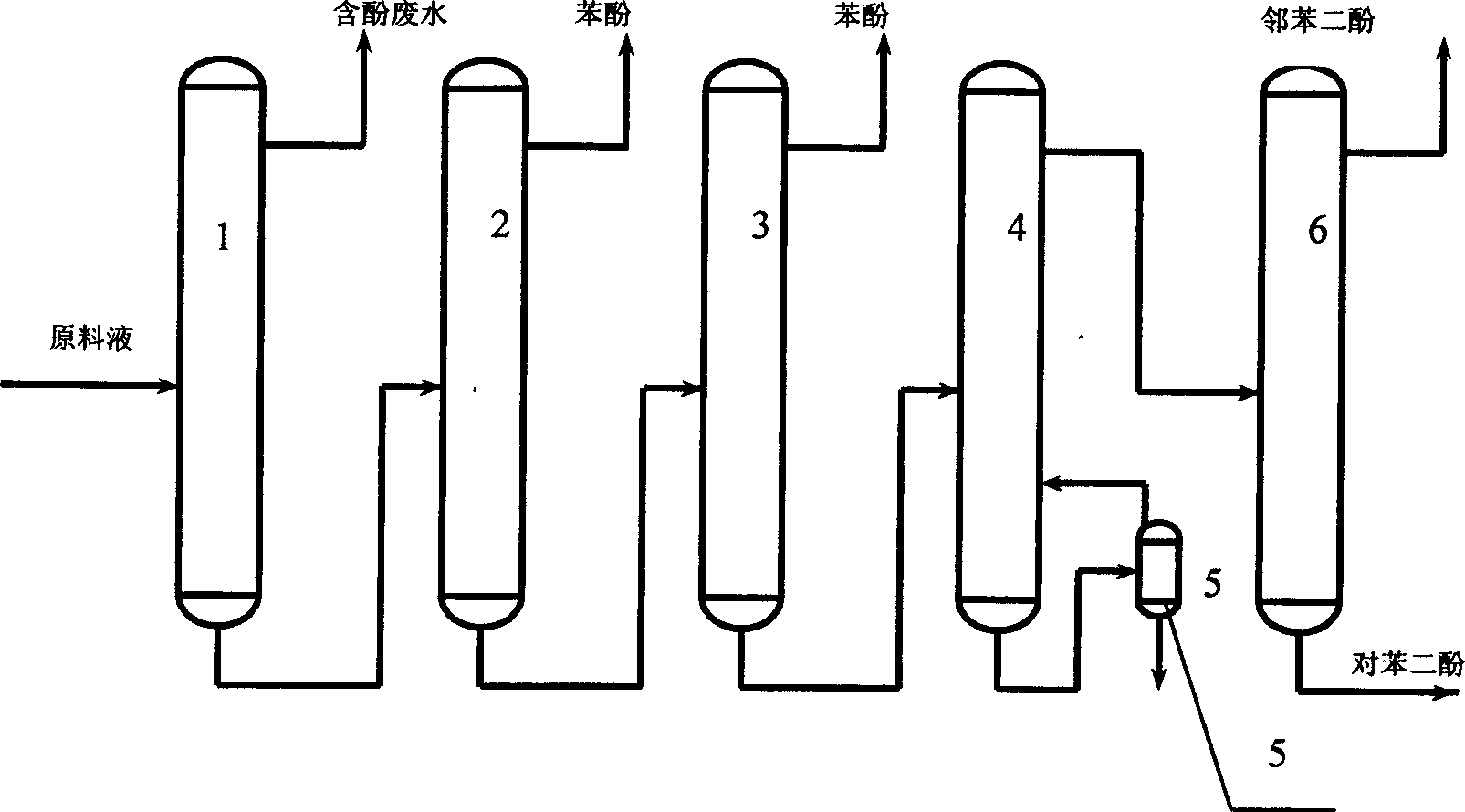

[0027]The raw material liquid is passed into the dehydration distillation tower with the flow rate of 4200kg / h, and the raw material liquid is composed of 20% water, 68% phenol, 3% catechol, 5% hydroquinone and 4% tar, and the waste water containing phenol is obtained from The top of the dehydration distillation tower is discharged, and the raw material liquid is sent into the first dephenol distillation tower from the bottom of the tower after dehydration, and the operating pressures in the dehydration distillation tower and the first dephenol distillation tower are respectively 50kPa and 10kPa; The pressure difference from the bottom of the tower is 1kPa and 2kPa respectively, and the temperature in the tower is 80-150°C; phenol is distilled from the upper part of the first dephenolization distillation tower, and the liquid after one separation of phenol is from the bottom of the first dephenolization distillation tower Send it into the second dephenolization distillation tow...

Embodiment 2

[0029] The raw material liquid is passed into the dehydration distillation tower with a flow rate of 20000kg / h. The raw material liquid consists of 50% water, 30% phenol, 9% pyrocatechol, 9% hydroquinone and 2% tar, and the phenolic waste water is obtained from The top of the dehydration distillation tower is discharged, and the raw material liquid after dehydration is sent into the first dephenol distillation tower from the bottom of the tower, and the operating pressures in the dehydration distillation tower and the first dephenol distillation tower are respectively 20kPa and 12kPa; The pressure difference from the bottom of the tower is 1.5kPa and 2.5kPa respectively, and the temperature in the tower is 65-140°C; phenol is distilled from the upper part of the first dephenolization distillation tower, and the liquid after one separation of phenol is distilled from the first dephenolization distillation tower. The bottom of the tower is sent to the second dephenolization disti...

Embodiment 3

[0031] The raw material liquid is passed into the dehydration distillation tower with a flow rate of 10500kg / h. The raw material liquid consists of 70% water, 20% phenol, 6% pyrocatechol, 3% hydroquinone and 1% tar, and the phenolic waste water is obtained from The top of the dehydration distillation tower is discharged, and the raw material liquid is sent into the first dephenol distillation tower from the bottom of the tower after dehydration, and the operating pressures in the dehydration distillation tower and the first dephenol distillation tower are respectively 35kPa and 11kPa; The pressure difference from the bottom of the tower is 2kPa and 3kPa respectively, and the temperature in the tower is 75-145°C; phenol is distilled from the upper part of the first dephenolization distillation tower, and the liquid after one separation of phenol is from the bottom of the first dephenolization distillation tower Send into the second dephenolization distillation tower with 2100kg / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| freezing point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com