Method for determining multiple brightening agents in nickel plating solution

A technology of brightener and nickel plating, which is applied in the field of liquid chromatography analysis, can solve problems such as the inability to examine the content of brightener and the reasonable compatibility of brightener, and achieve the effects of increasing quality control capabilities, shortening measurement time, and reducing testing investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

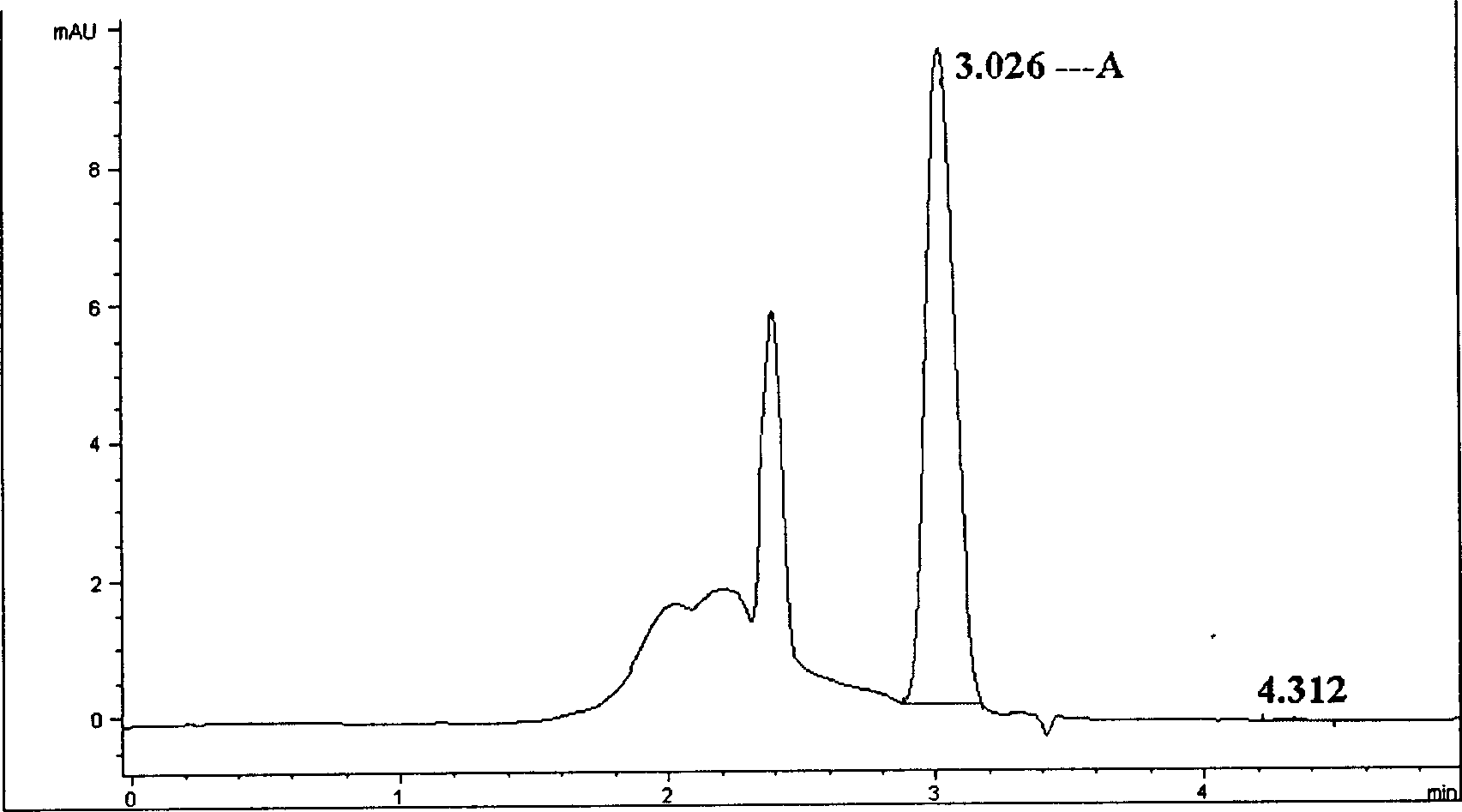

Image

Examples

Embodiment

[0019] Step 1: Weigh 300g of nickel sulfate, 40g of nickel chloride, and 40g of boric acid, and dissolve them in 1L of purified water heated to about 80°C. Prepare 1L of blank electroplating solution without any brightener.

[0020] Step 2: Prepare a series of mixed standard solutions containing brighteners A, B and C, wherein brightener A is 1,4-butynediol; brightener B is 1,4-butynedicyanide; brightener C is sodium saccharin. The concentration of each standard solution is shown in Table 1. Take standard solution 1 as an example to illustrate the preparation method.

[0021] Pipette 0.03mL brightener A, 0.20mL brightener B, and 0.30mL brightener C into 100mL volumetric flasks, and use the blank plating solution prepared in step 1 without any brightener to make up to 100mL to obtain a standard solution 1. The remaining standard solution preparation methods can be obtained by pipetting corresponding volumes of brightener A, brightener B and brightener C respectively accordi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com