Serial combustion system and method for load control of circulating fluidized bed boiler

A technology of circulating fluidized bed and boiler load, which is applied in the direction of fluidized bed combustion equipment, combustion method, and fuel burned in a molten state, can solve problems such as overshoot of main steam pressure, and achieve the effect of improving quality and good control effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order for those skilled in the art to fully understand the purpose, features and effects of the present invention, the present invention will now be described in detail through the following specific embodiments in conjunction with the accompanying drawings.

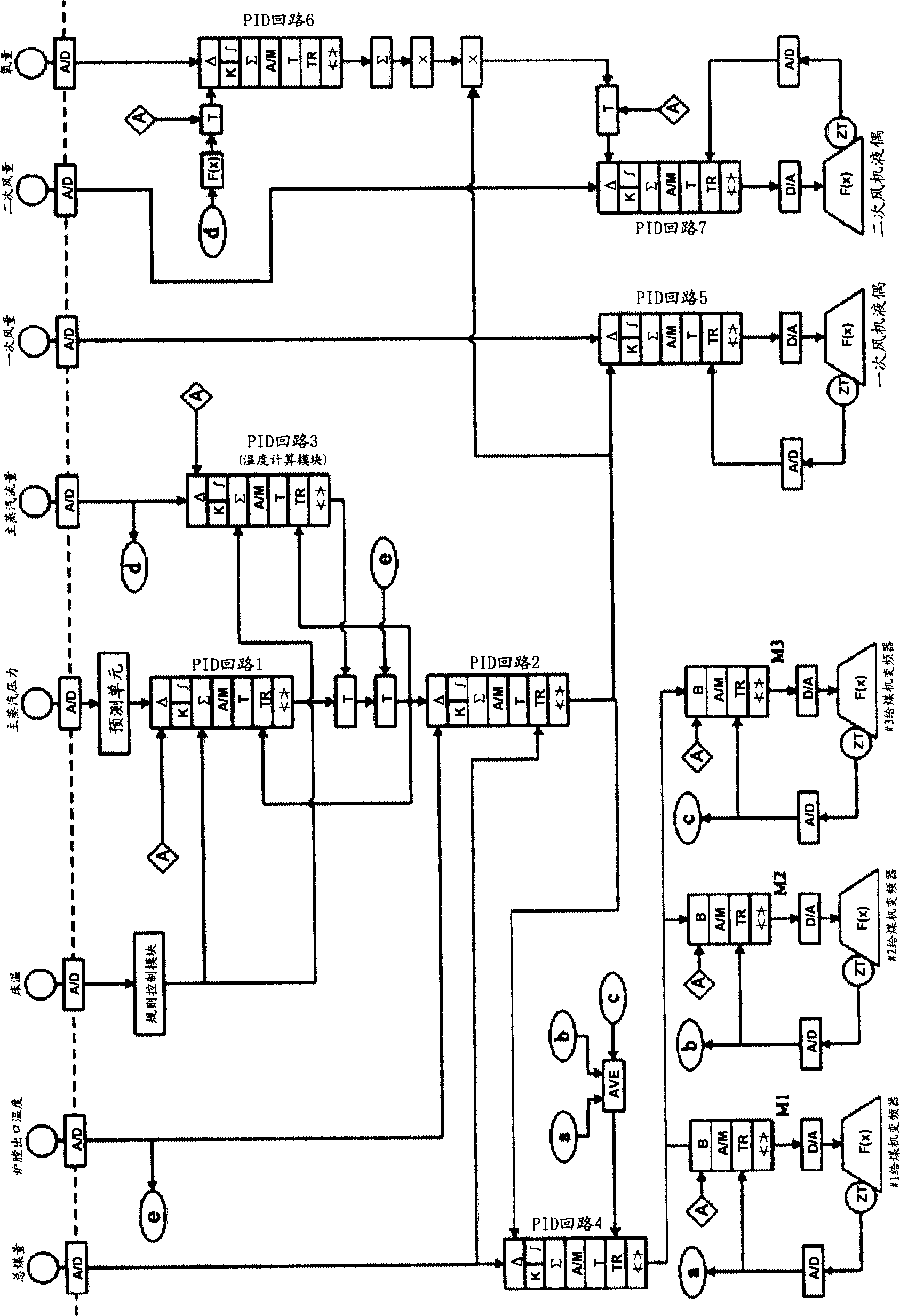

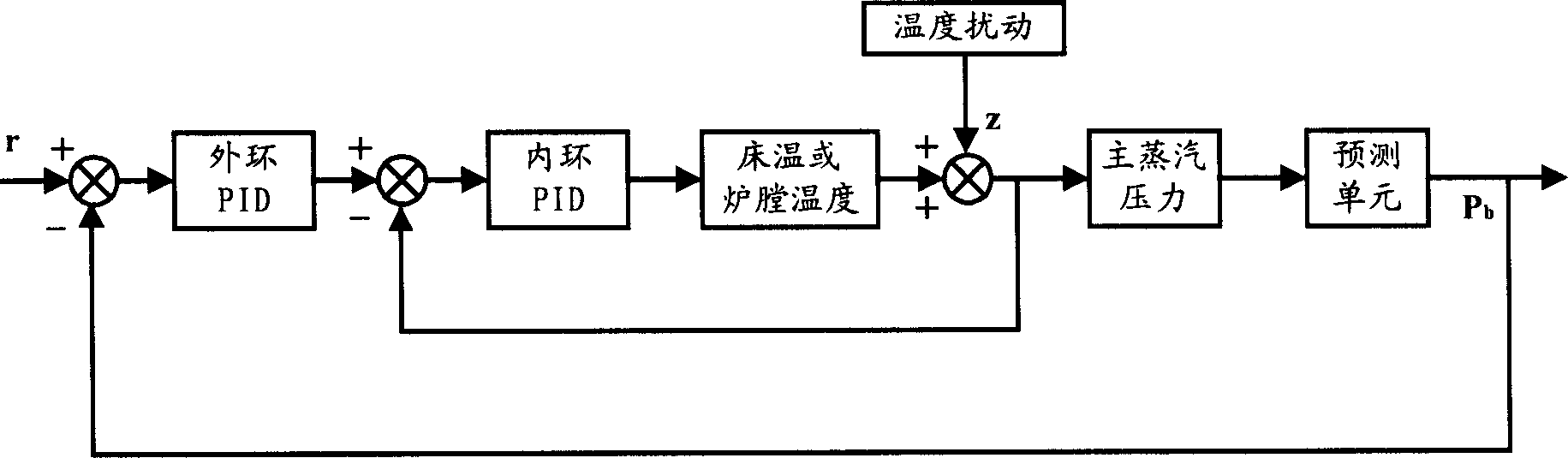

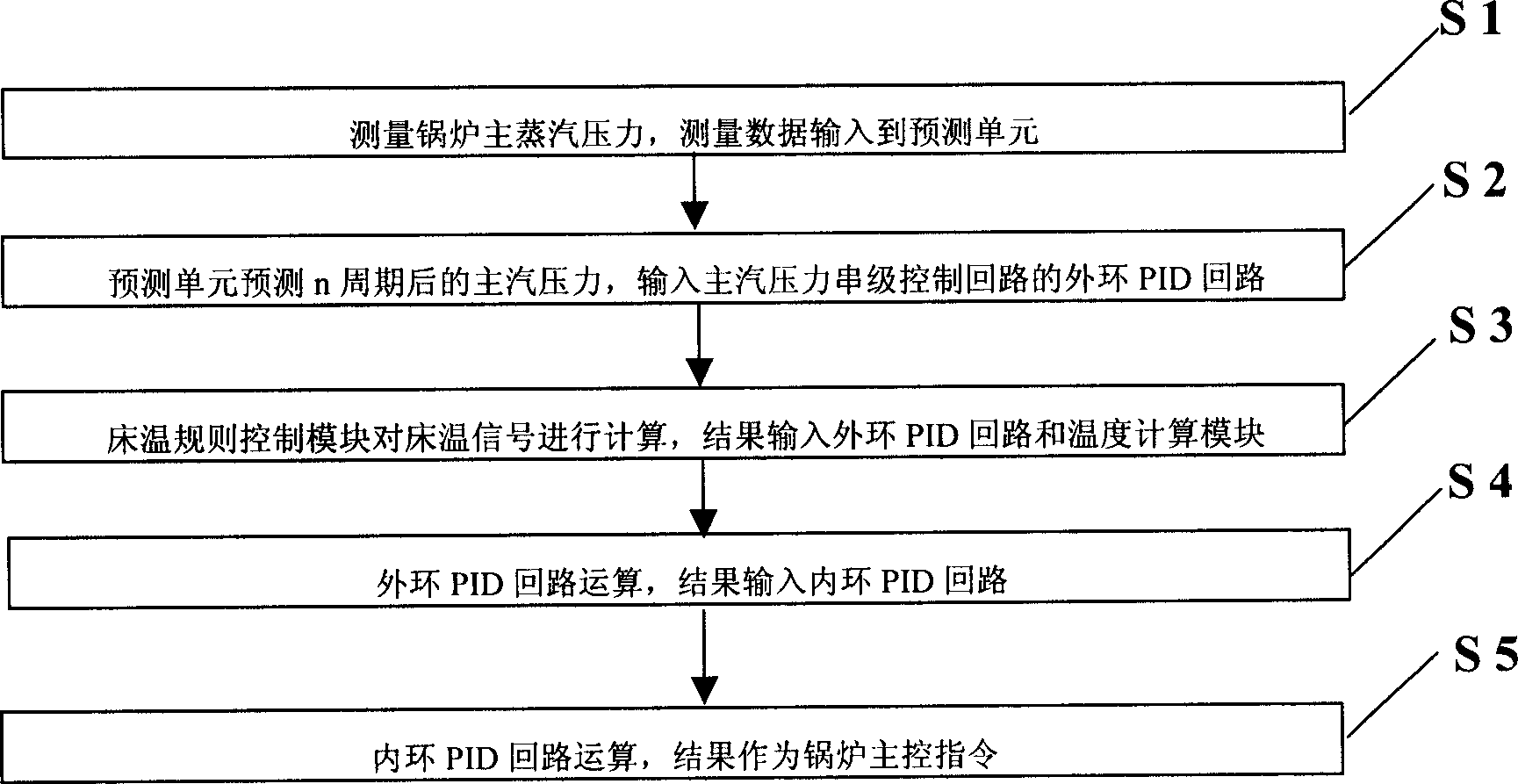

[0034] see figure 1 , in the structural schematic diagram of the combustion control system of the present invention, the prediction unit, that is, the main steam pressure prediction unit, receives externally input boiler main steam pressure measurement value data (that is, main steam pressure data), and the main steam pressure measurement value data is obtained through the model. The prediction unit makes prediction calculations based on the received boiler main steam pressure data, and outputs the calculation results to the outer loop proportional-integral-derivative PID loop of the main steam pressure cascade control loop (ie figure 1 The PID loop 1), implements the prediction algorithm. In the technical sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com