Cross current swirl type solid-liquid separation device

A solid-liquid separation, vortex technology, applied in cyclone devices, filtration separation, separation methods, etc., can solve the problems of accelerated water treatment, difficult operation and management, and many equipment, and achieves low operating failure rate and maintenance costs. , The effect of saving construction investment and compact device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

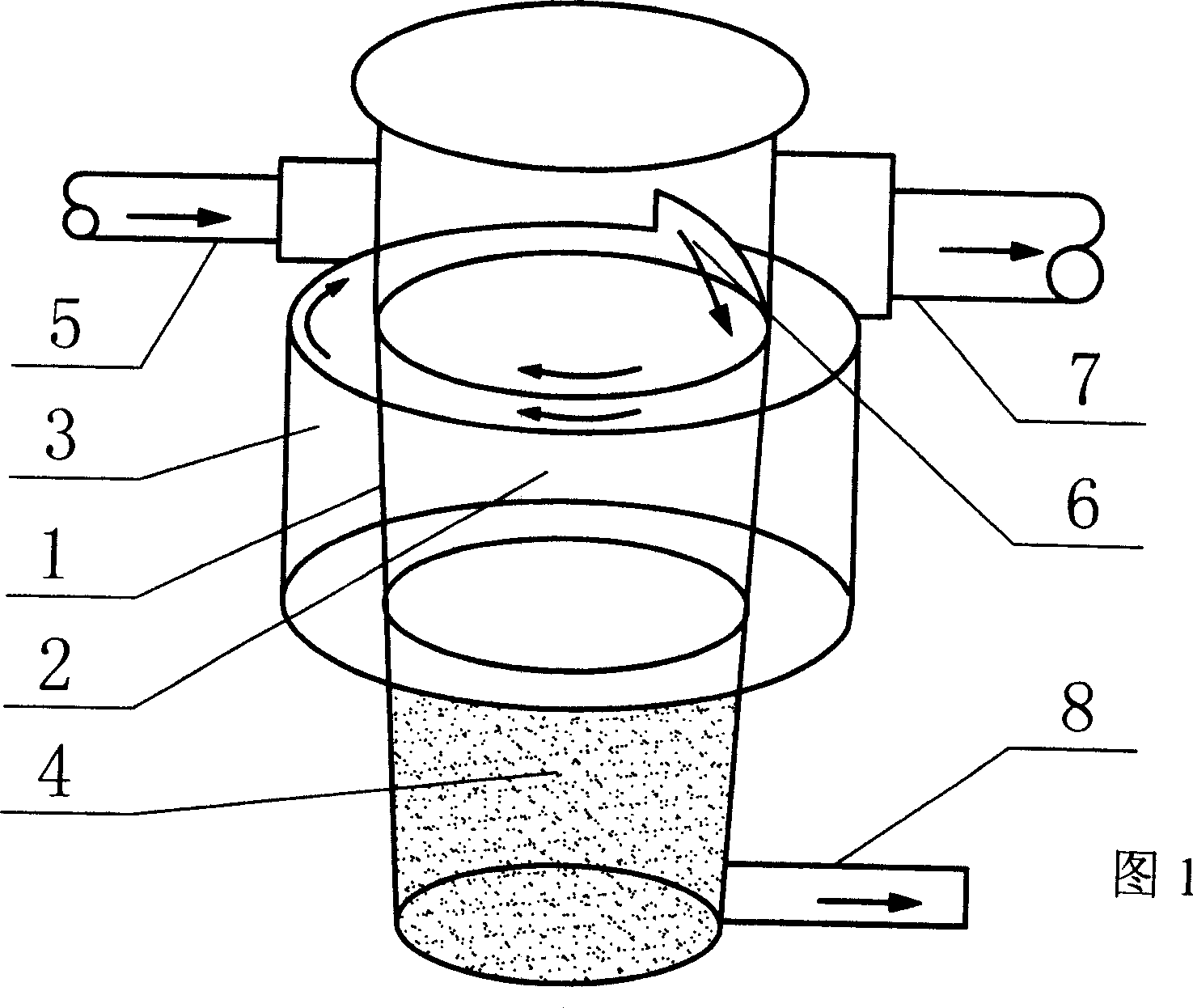

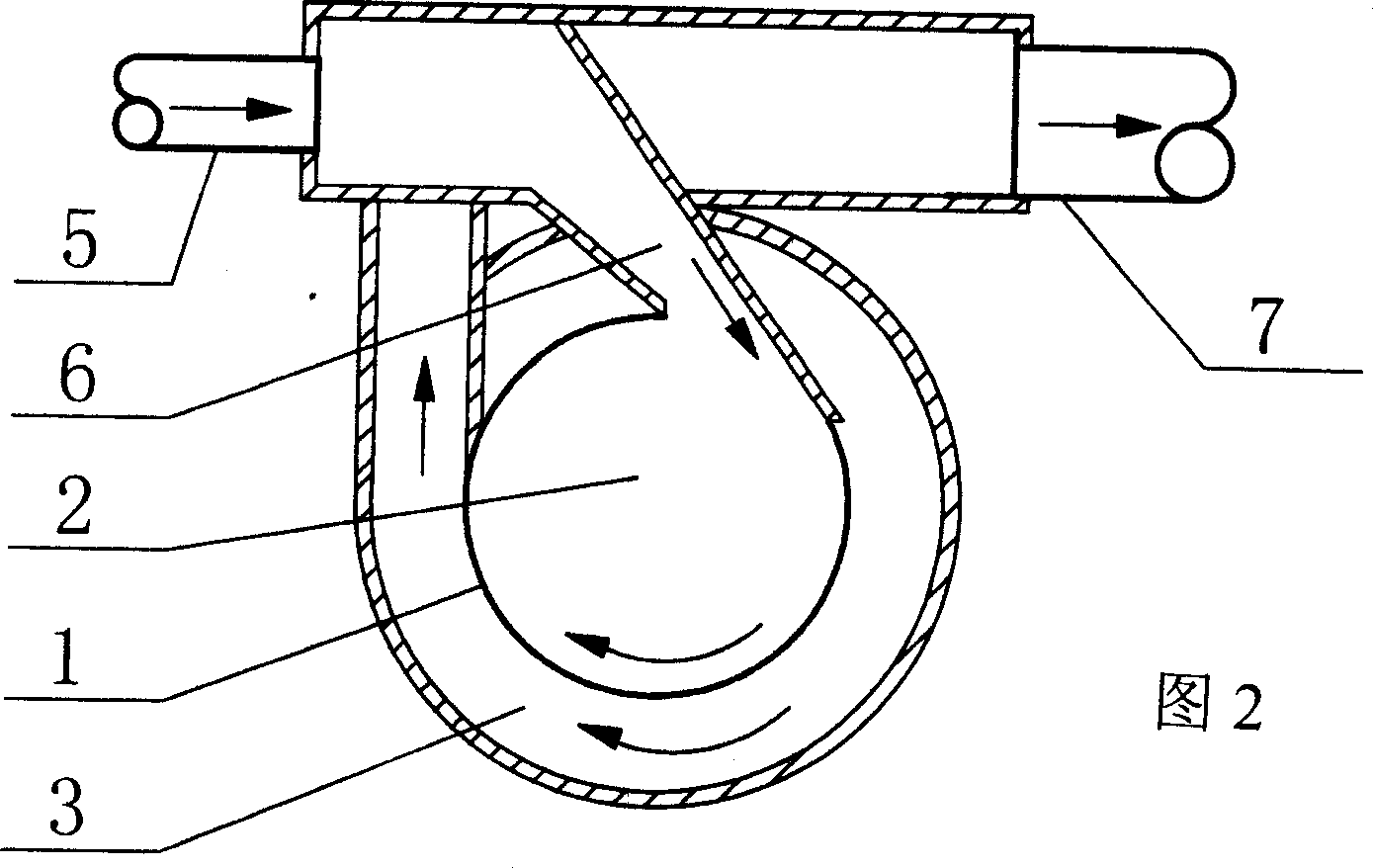

[0020] Referring to the accompanying drawings, this embodiment sets a cylindrical swirl chamber, which is divided into an inner chamber 2 and an outer chamber 3 on the same axis by a cylindrical retaining net 1, and the bottom of the inner chamber 2 Undertake the mud collection chamber 4, the water inlet pipe 5 is arranged along the tangential direction of the cylindrical cyclone chamber, the water inlet 6 is located above the inner chamber 2, and communicates with the inner chamber 2, and the incoming water flow is injected into the inner chamber according to the tangential direction 2. A tangential overflow drain pipe 7 is provided, and the drain pipe 7 communicates with the outer chamber 3; the bottom of the mud collection chamber 4 communicates with the mud discharge pipe 8.

[0021] The technical parameter of device of the present invention can be set to:

[0022] Hydraulic retention time: 5 to 50 seconds

[0023] Inlet water head: 0.5~5 meters

[0024] Retention mesh d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com