Oil pump

A technology of oil pumps and shallow tanks, applied in the field of gear pumps, can solve the problems of bubble collapse (breakage, erosion, bubble collapse, etc.), and achieve the effects of improving durability, easy replenishment, and preventing erosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

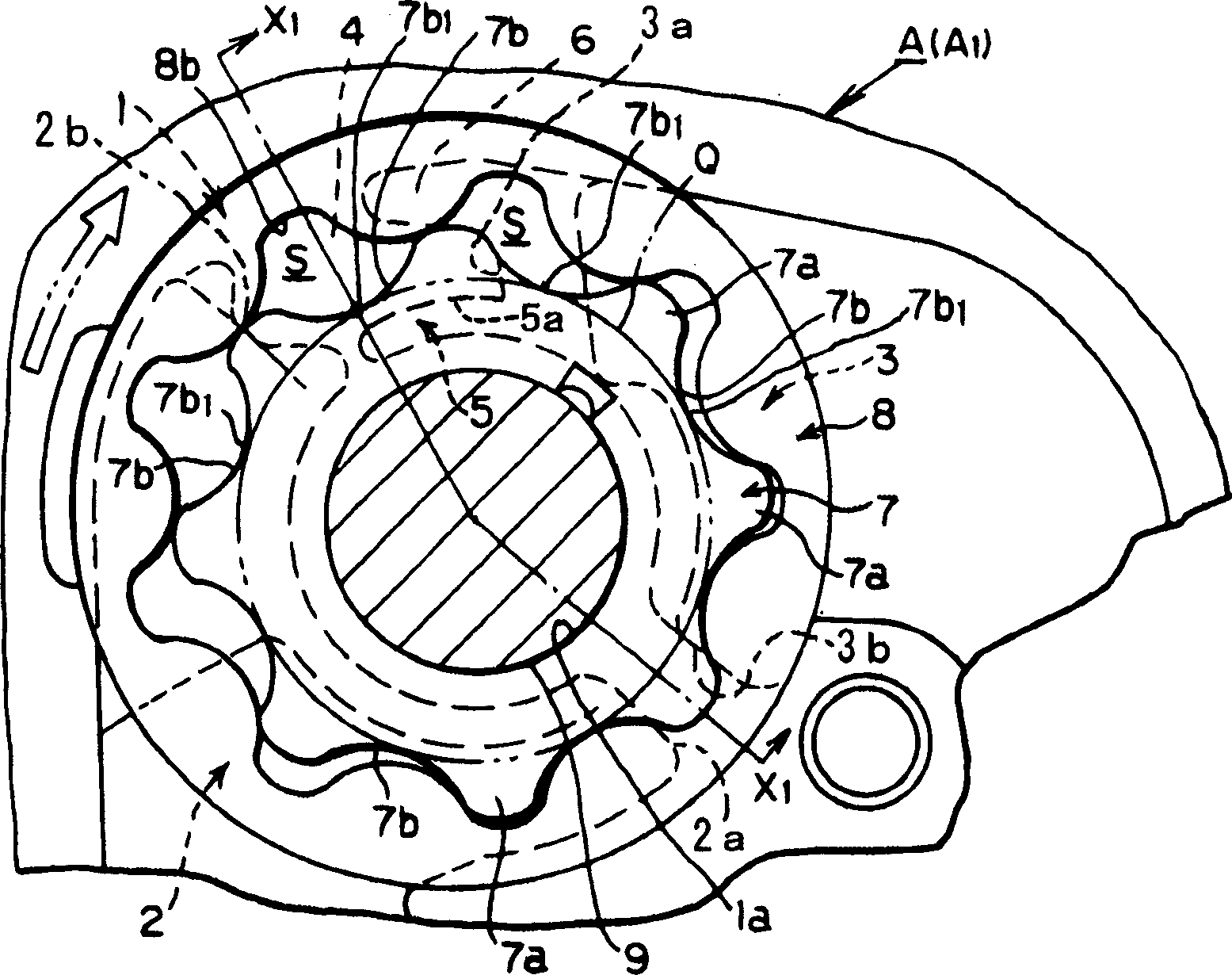

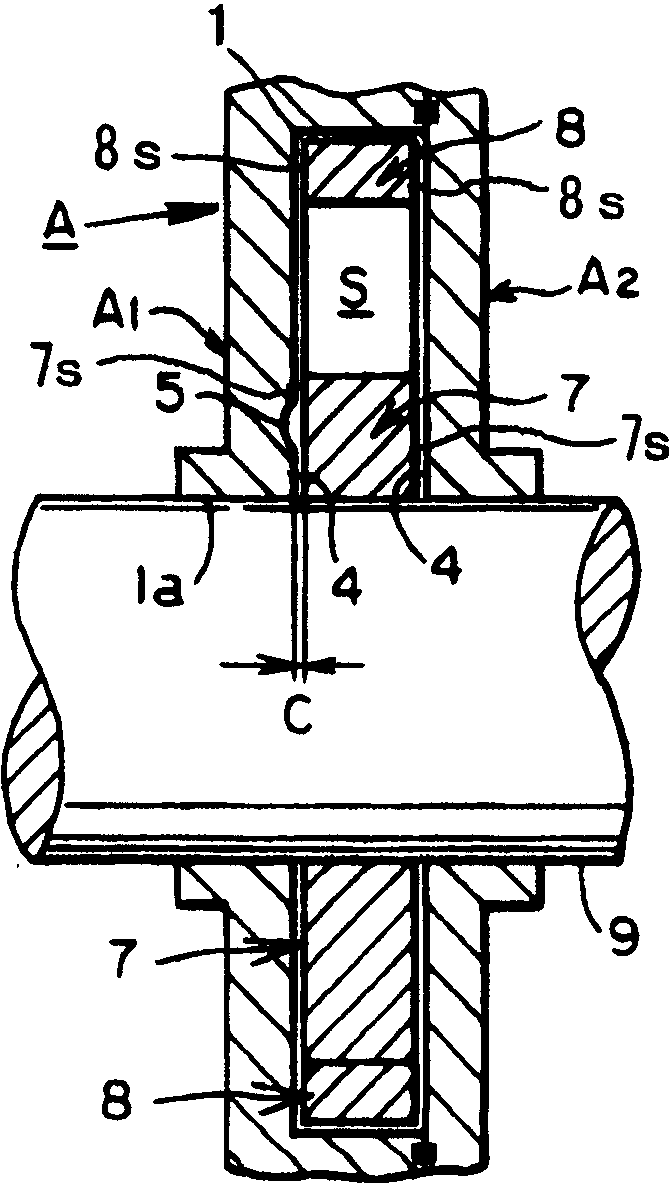

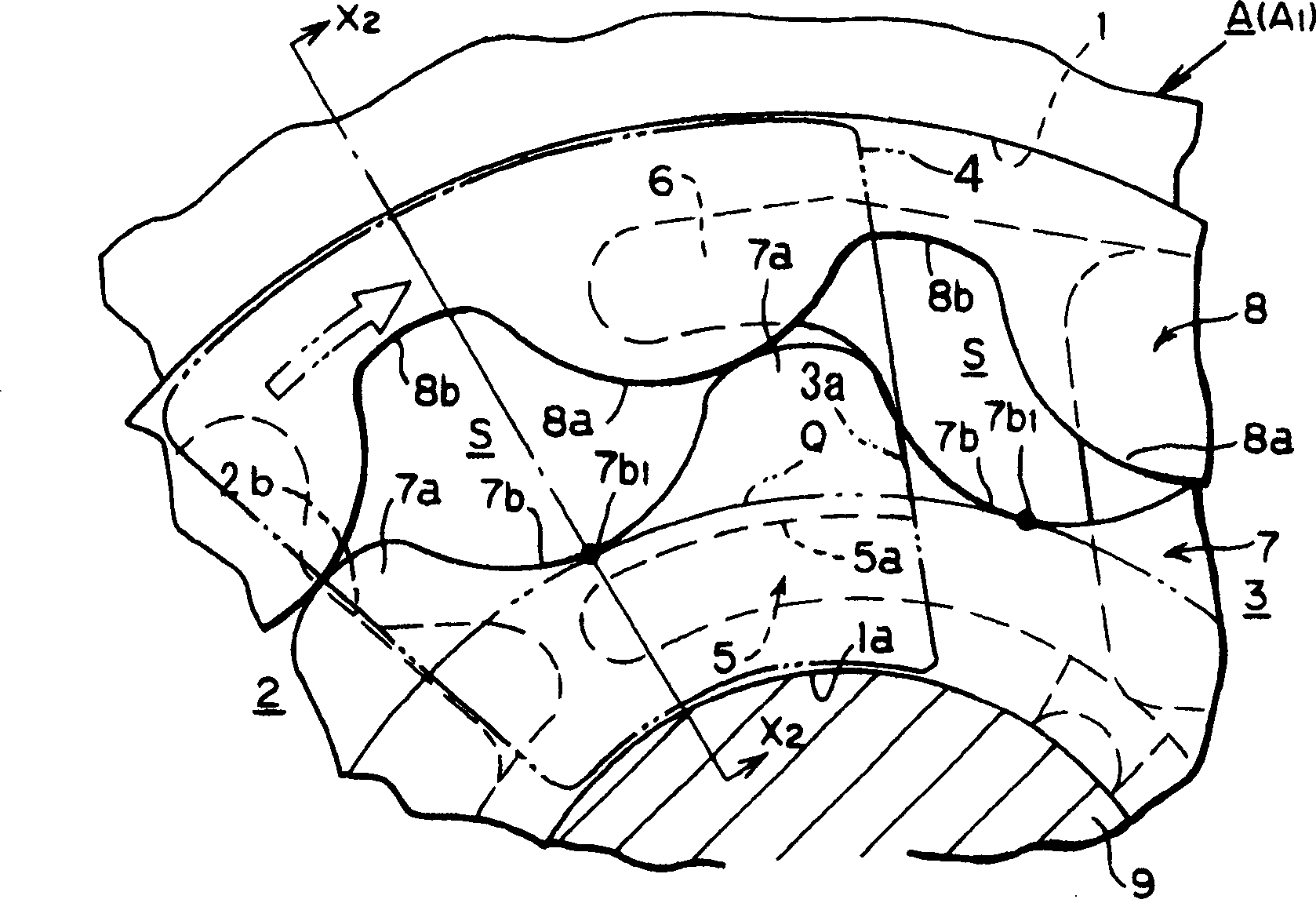

[0027] Embodiments of the present invention will be described below based on the drawings. Oil pump of the present invention, as Figure 1A As shown, in the rotor chamber 1 formed in the casing A, the inner rotor 7 and the outer rotor 8 having a trochoid tooth shape are housed. Fig. 2 is the housing body part A of the housing A 1 The top view of the main part, in the aforementioned rotor chamber 1, such as Figure 2A As shown, a suction port 2 and a discharge port 3 are formed on its substantially outer periphery along its circumferential direction. The suction port 2 and the discharge port 3 are formed asymmetrically in the rotor chamber 1 . Alternatively, the suction port 2 and the discharge port 3 may be bilaterally symmetrical.

[0028] Such as Figure 1A As shown, the number of teeth of the inner rotor 7 is one less than that of the outer rotor 8, and there is a relationship that when the inner rotor 7 makes one revolution, the outer rotor 8 rotates slower than that. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com