Showerhead engine assembly

A technology for shower heads and appliances, applied in showers, bathtubs, jet devices, etc., can solve the problems of expensive manufacturing, blocked outlet holes, etc., and achieve the effect of reducing spare parts, reducing the number of parts, and shortening assembly time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

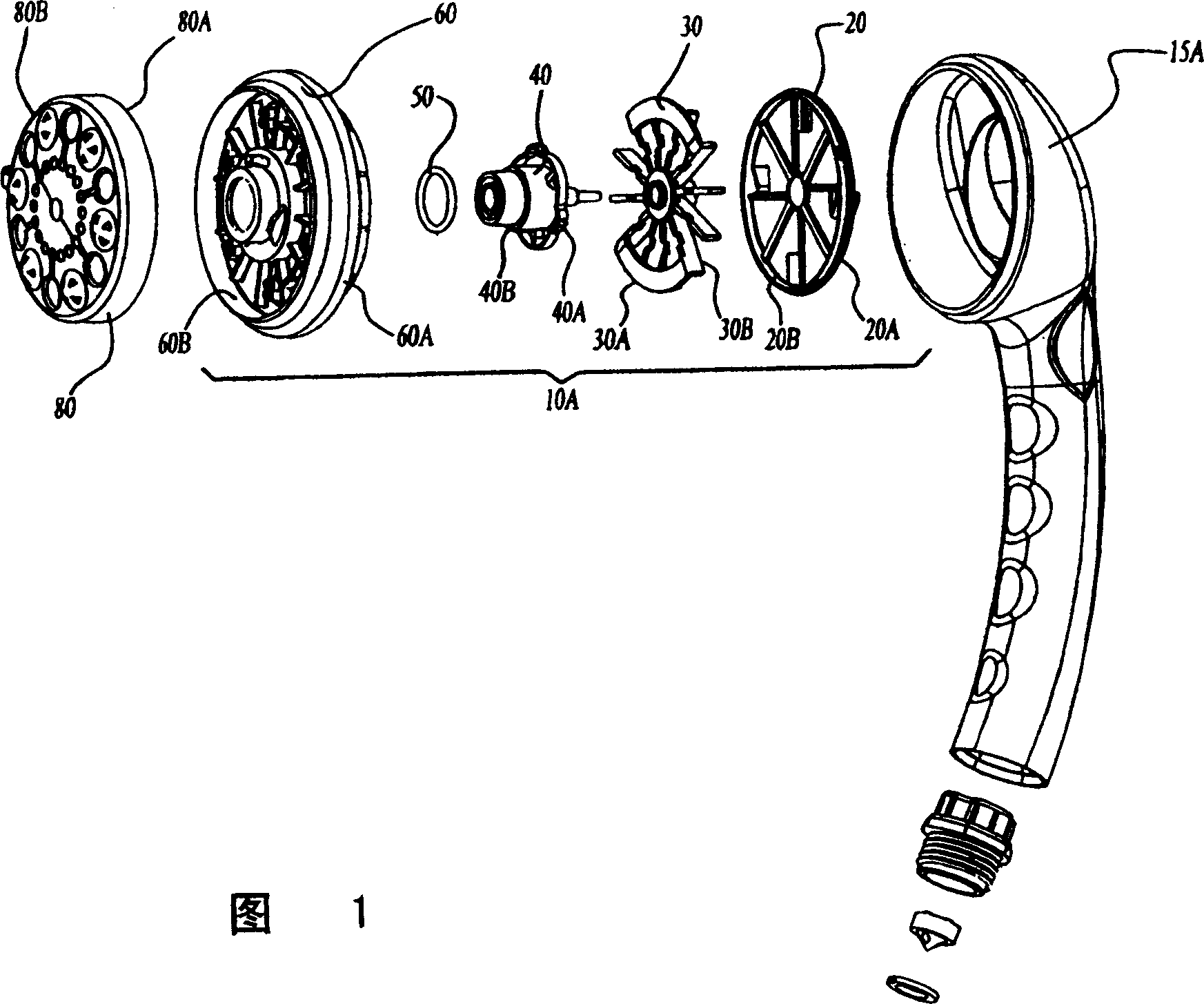

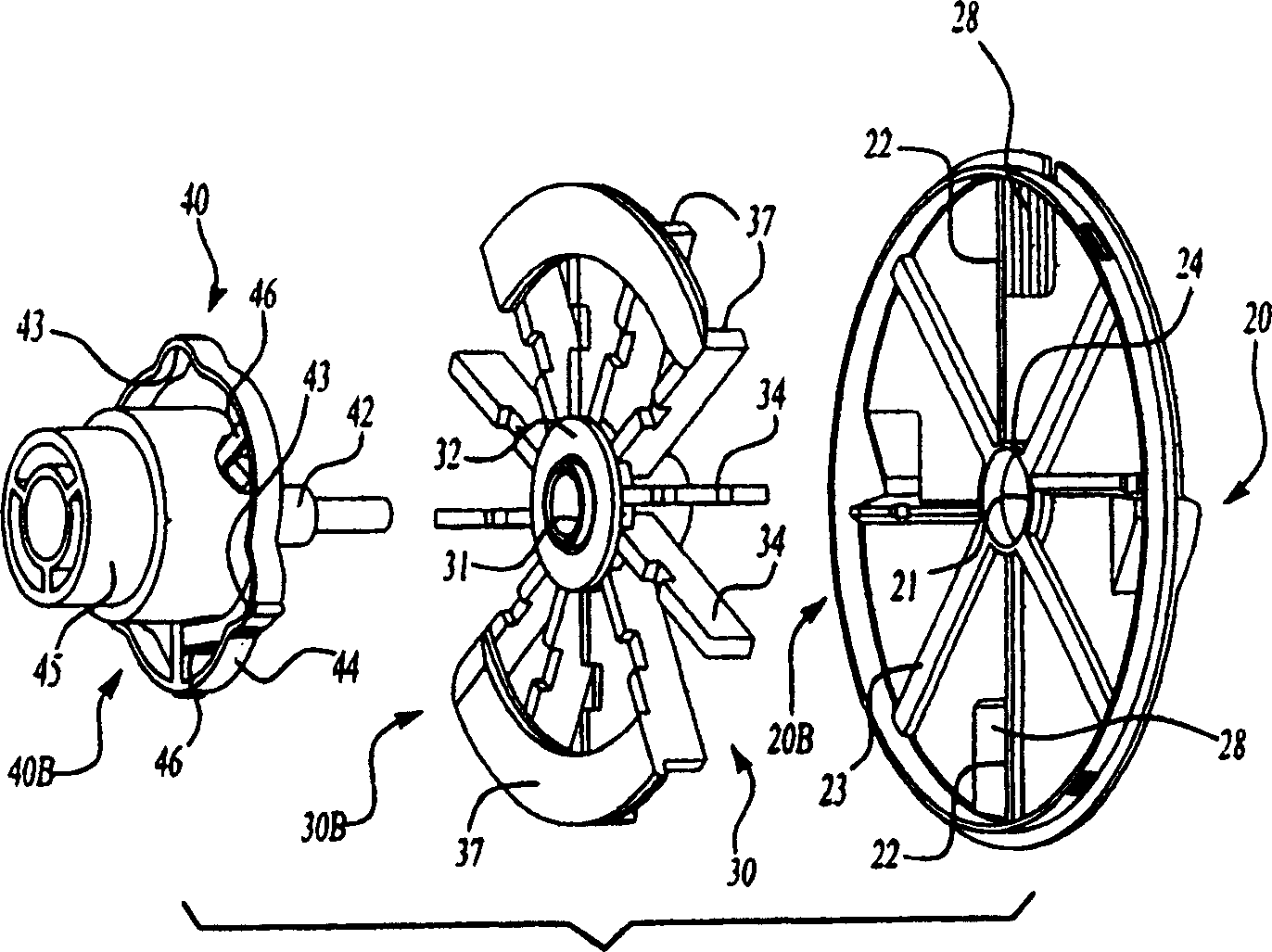

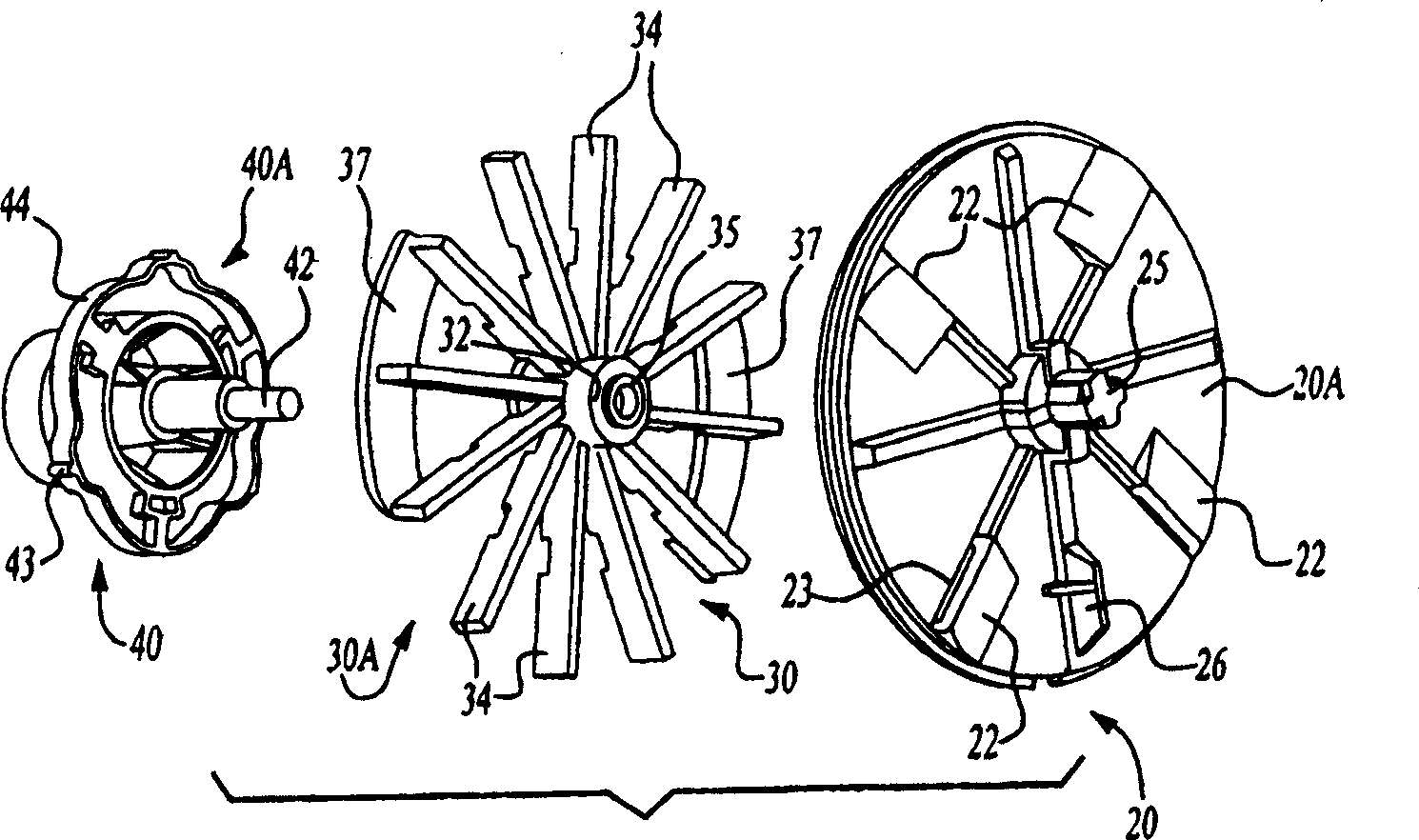

[0037] Referring first to the drawings, FIG. 1 discloses an assembled view of a preferred embodiment of a hand-held embodiment of a showerhead appliance assembly 10A of the present invention. Figures 7a, 7b, 8a, 8b and 8c give additional views of the hand showerhead housing and shroud 15A. The shower head appliance assembly 10 of the present invention includes a stationary part 20 , a rotating part 30 , an engaging part 40 , a sealing ring 50 , a pressure plate 60 and a panel 80 .

[0038] High pressure water at about 137895.2 to 551580.8 Pa (20 to 80psi (lb / in 2 ) into the rear end of the shower head housing of the present invention, 551580.8 Pa (80 lbs / in 2 ) with a maximum flow rate of 9.4625 L / min (2.5 GPM). Water is pushed through the stationary member 20 into the rotating member 30 , into and through the pressure plate 60 , and exits through the panel 80 . The rotating member 30 , the sealing ring 50 and the engaging member 40 are inserted into the pressure plate 60 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com