High protein nutritious bread containing degreased walnut powder and its production method

A high-protein, production method technology, applied in the direction of baked food with modified ingredients, etc., can solve the problems of product rheological properties and sensory quality effects, and achieve the effects of improving texture and taste, increasing content, and increasing nutrition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

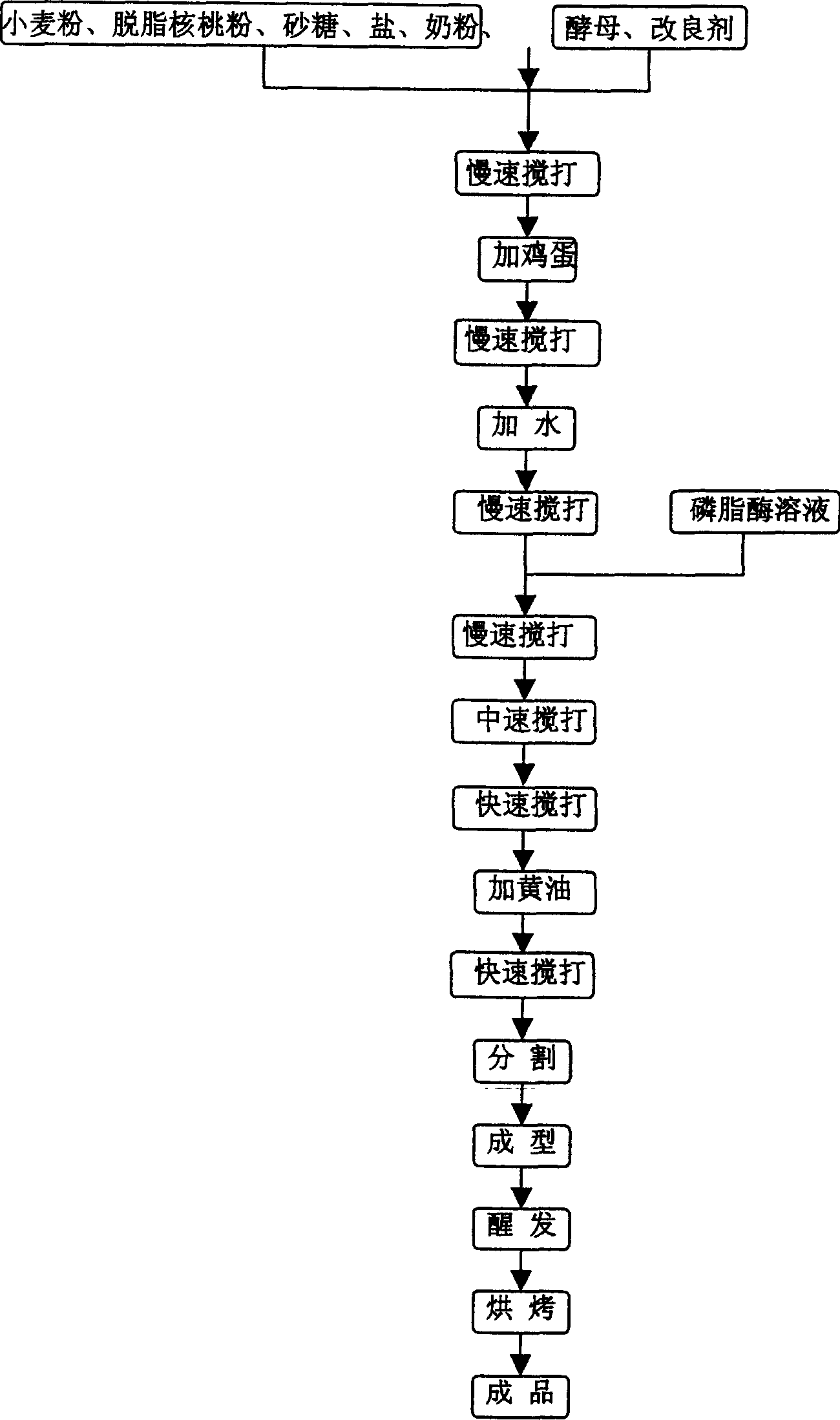

Image

Examples

Embodiment 1

[0021] In the embodiment of the present invention, wheat flour: 50.9994% by weight; defatted walnut powder: 3% by weight; granulated sugar: 11% by weight; milk powder: 2% by weight; yeast: 0.8% by weight; improver: 0.4% by weight; Water: 6% by weight; Egg: 15% by weight; Butter: 10% by weight; Salt: 0.8% by weight; Phospholipase: 0.0006% by weight.

[0022] In the present invention, phospholipase is dissolved in an appropriate amount of water to prepare an enzyme solution, the solution concentration is: 3% by weight, and placed in a constant temperature incubator at 28°C for activation; wheat flour, defatted walnut powder, granulated sugar, milk powder, salt, yeast, and improved Add the agent into the noodle mixer and stir at a slow speed for 1 minute; add eggs and whip at a slow speed for 1 minute; add water (the remaining part of the enzyme solution), and continue to whip for 2 minutes; add the activated phospholipase solution and continue to slowly Beat at high speed for 8 ...

Embodiment 2

[0024] In the embodiment of the present invention, wheat flour is 46% by weight; almond skin powder is 6% by weight; active gluten powder is 0.7% by weight; sugar is 10% by weight; milk powder is 1.5% by weight; yeast is 0.6% by weight %; improver: 0.4% by weight; water: 6% by weight; egg: 18% by weight; butter: 10% by weight; salt: 0.8% by weight.

[0025] In the present invention, phospholipase is dissolved in an appropriate amount of water to prepare an enzyme solution, the solution concentration is: 4% by weight, and placed in a constant temperature incubator at 30°C for activation; wheat flour, defatted walnut powder, granulated sugar, milk powder, salt, yeast, and improved Add the agent into the noodle mixer and stir for 1 minute at a slow speed; add eggs and beat for 2 minutes at a slow speed; add water, continue to beat for 2 minutes at a slow speed, add the activated phospholipase solution, continue to beat for 9 minutes at a slow speed, and then Beat at medium speed ...

Embodiment 3

[0027] In the embodiment of the present invention, wheat flour: 46.5% by weight; defatted walnut powder: 4.5% by weight; sugar: 10% by weight; milk powder: 1.5% by weight; yeast: 0.8% by weight; improver: 0.4% by weight; Water: 5.7992% by weight; Egg: 20% by weight; Butter: 10% by weight; Salt: 0.5% by weight; Phospholipase: 0.0008% by weight.

[0028] In the present invention, the phospholipase is dissolved in an appropriate amount of water to prepare a solution, the concentration of the solution is: 5% by weight, and it is placed in a constant temperature incubator at 32°C to be activated for use; wheat flour, defatted walnut powder, granulated sugar, milk powder, salt, yeast, and improver Add to the noodle mixer and stir at a slow speed for 1 minute; add eggs and beat at a slow speed for 2 minutes; add water (the remaining part of the enzyme solution), continue to beat at a slow speed for 2 minutes, add the activated phospholipase solution, and continue to stir at a slow spe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com