High-tension element structure

A technology of high-voltage components and conductivity types, applied in the field of high-voltage component structures that can suppress parasitic currents, can solve problems such as unpredictable output current and voltage characteristics, and achieve the effect of being conducive to small size and suppressing parasitic currents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

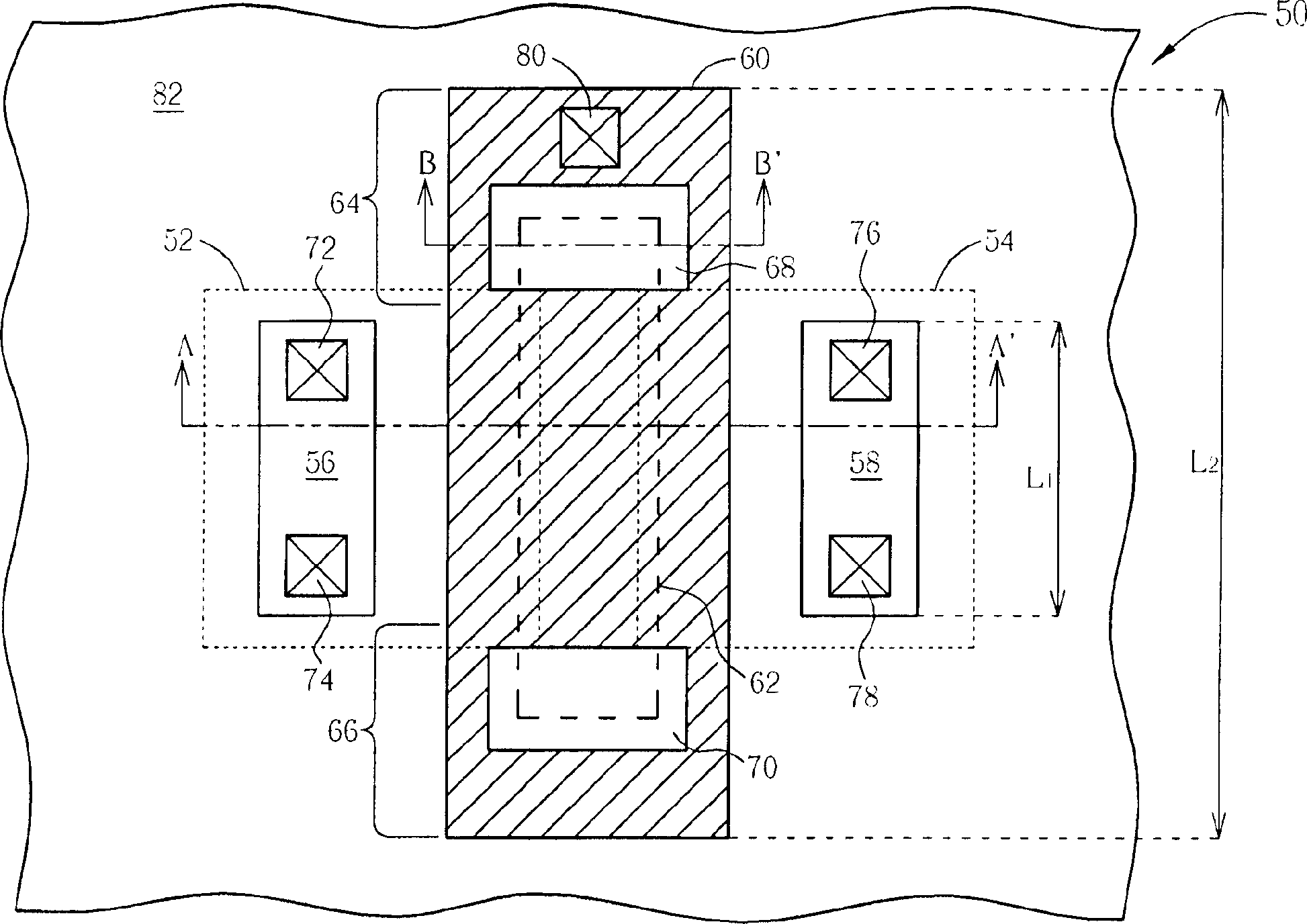

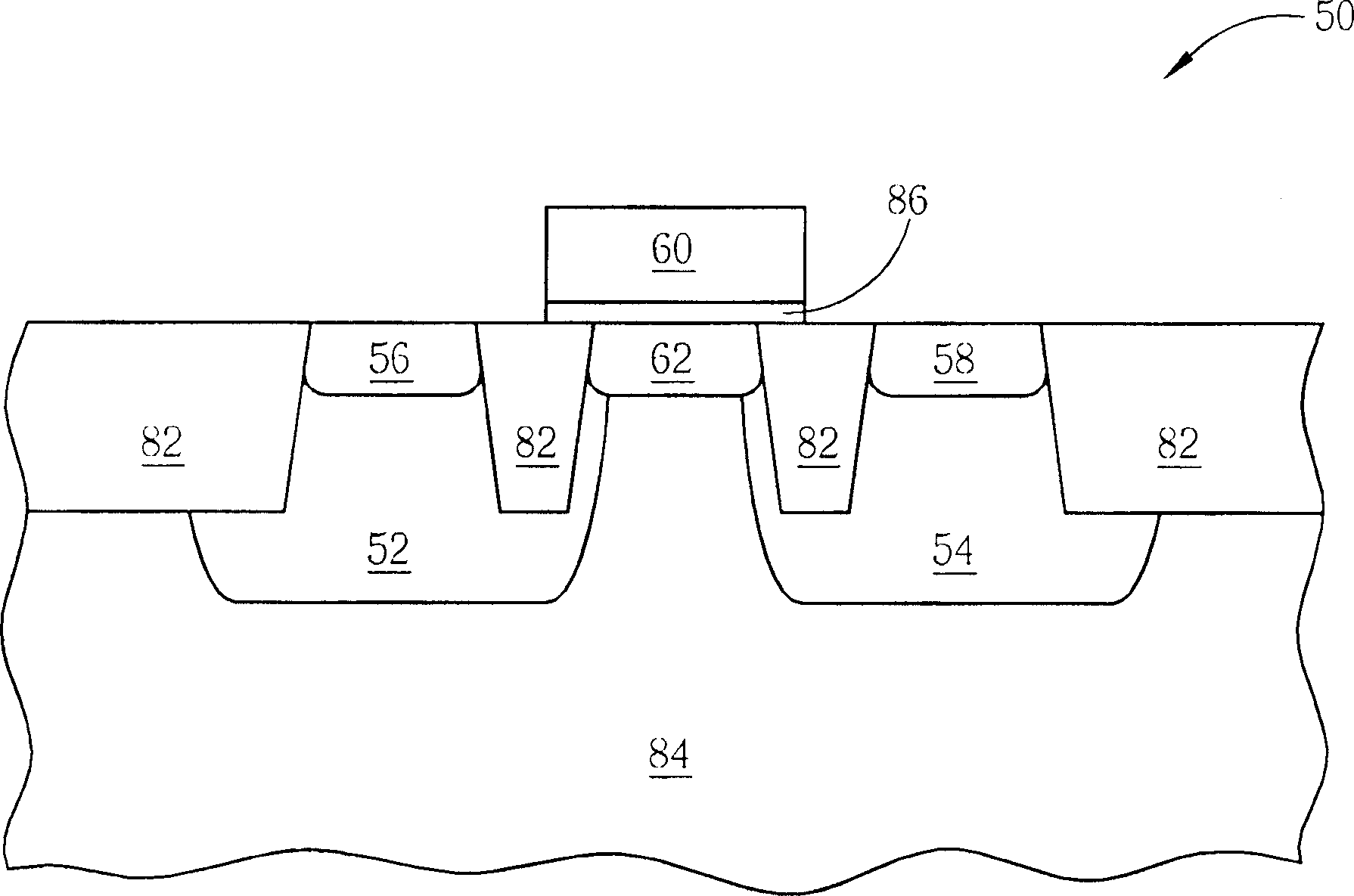

[0031] Please refer to figure 2 , figure 2 It is a top view of the high voltage element structure 50 of the present invention. like figure 2 As shown, the high-voltage element structure 50 of the present invention is disposed in a substrate (not shown) of a first conductivity type, and the high-voltage element structure includes a first well region 52 (shown by a dotted line) having a second conductivity type region) and a second well region 54 (the region shown by the dotted line) are located in the substrate and have a first length L 1 A source diffusion region 56 and a drain diffusion region 58 are respectively located in the first well region 52 and the second well region 54, and have a second length L 2 A conductive gate layer 60 is located on the surface of the substrate, and a channel diffusion region 62 (the region shown by the dotted line) is located in the substrate covered by the conductive gate layer 60 and is located above part of the first well region 52 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com