Sliding intelligent inclinometer

An inclinometer and sliding technology, which is applied in the field of sliding intelligent inclinometers, can solve problems such as probe positioning errors, signal wire damage, and high labor intensity, and achieve high precision, low wear, and improved efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

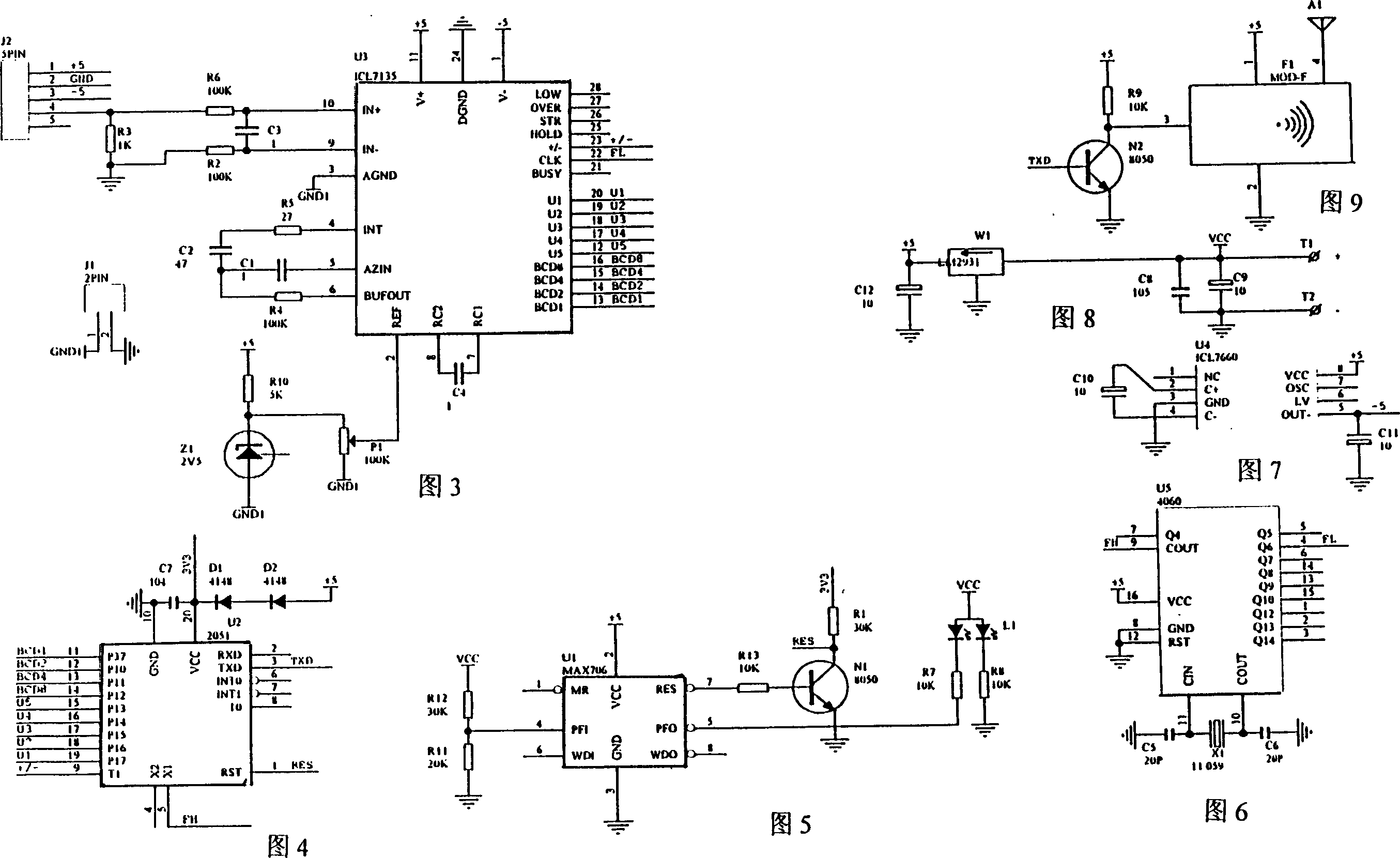

[0029] According to the accompanying drawings, its structure is composed of receiving and data processing controllers, winding machines, data acquisition and transmitting controllers. Among them, the measuring controller 1 in the receiving and data processing controllers communicates with the winding machine through the control line 4. The control panel 5 is connected, the signal cable 9 in the winding machine is connected with the measuring probe 12 in the data acquisition and emission controller through the length meter 10, and the data acquisition transmitter 13 in the data acquisition and emission controller is connected by wireless Transmit to receive, data wireless receiver 2 in the data processing controller.

[0030] The receiving and data processing controller includes a measurement controller 1 , a wireless data receiver 2 and a data storage 3 .

[0031] The winding machine includes a control wire 4 , a control panel 5 , a driving motor 6 , a transmission belt 7 , a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com