Back flow preventer

A technology of backflow prevention and check valve, which is applied in the direction of valve operation/release device, function valve type, transportation and packaging, etc. It can solve the problem of backflow preventer cleaning machine damage and achieve the effect of small structure volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

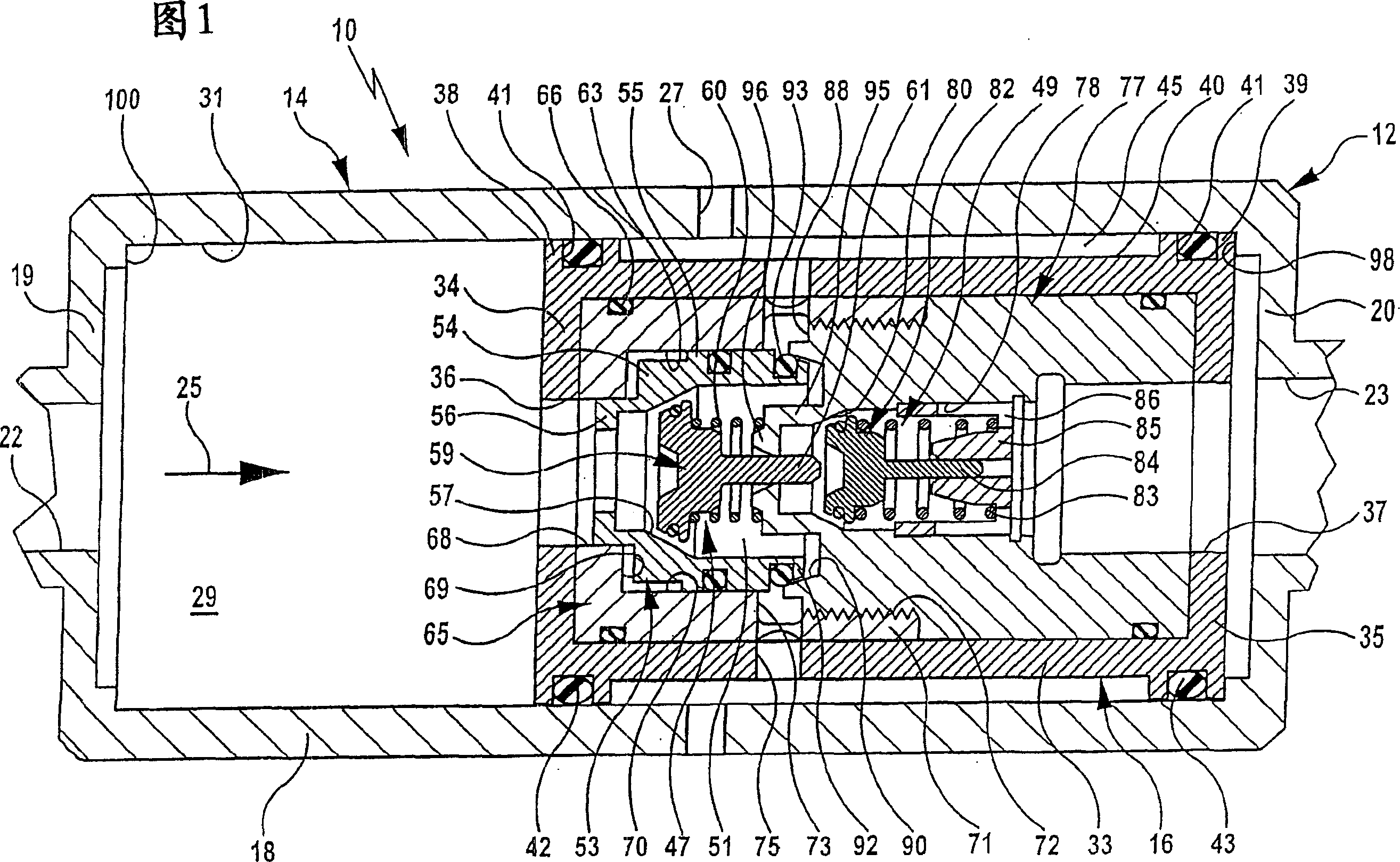

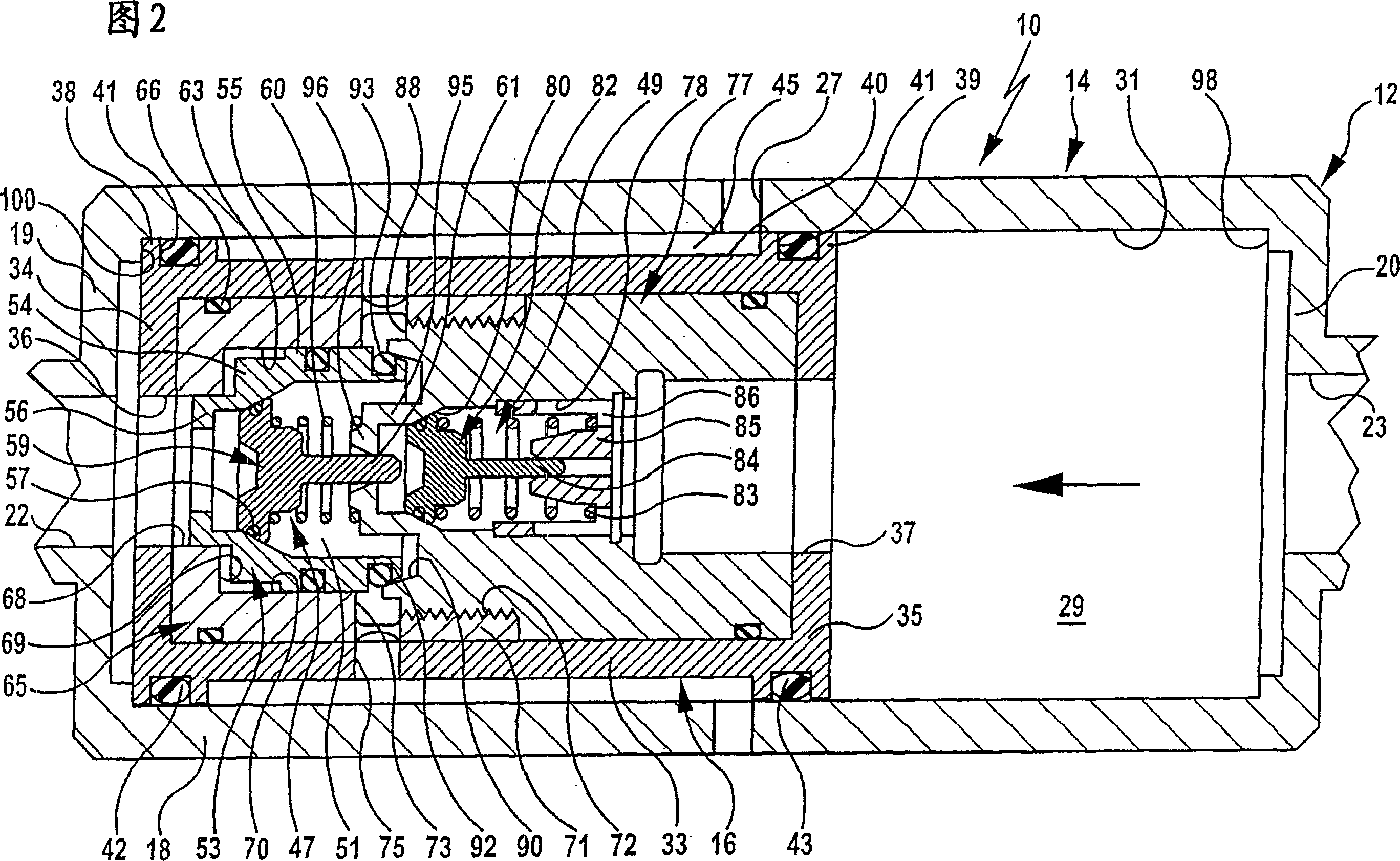

[0026] There is shown a backflow preventer, generally designated by the reference numeral 10 , having a two-piece housing 12 with a hollow cylindrical outer shell 14 and an inner shell 16 movably retained within the outer shell 14 .

[0027] The housing 14 has a housing cylinder 18 which is connected to a housing top 19 and a housing bottom 20 . An inlet 22 is formed on the housing top 19 and an outlet 23 is formed on the housing bottom 20 . At least one, in particular a plurality of leakage openings 27 distributed over its circumference are formed on the housing cylinder 18 approximately centrally between the inlet 22 and the outlet 23 in the flow direction 25 .

[0028] The outer shell 14 encloses a receiving area 29 in which the inner shell 16 is held reciprocally movable in the flow direction 25 .

[0029]The inner casing 16 is also designed as a hollow cylinder and includes a sleeve 33 arranged at a certain distance from the inner wall 31 of the casing tube 18, which is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com