Oil-free vortex air conditioner compressor

An air-conditioning compressor and scroll technology, which is applied in the field of oil-free scroll air-conditioning compressors, can solve the problems of oil-free air-conditioning compressors that have not been disclosed, achieve simplified structure, avoid environmental pollution, and reduce production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

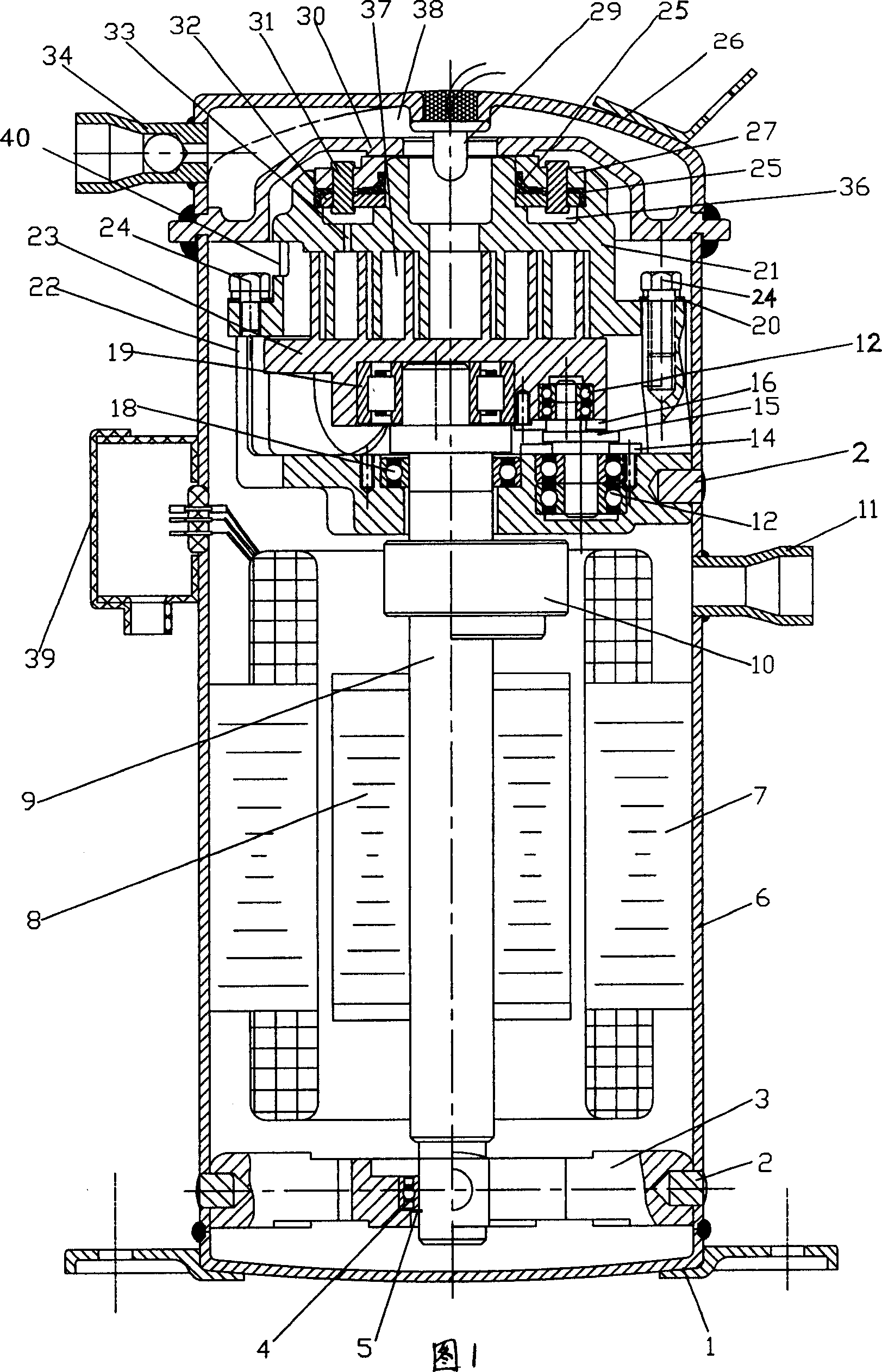

[0017] Embodiment 1, Fig. 1 is a 3HP fully enclosed oil-free flexible scroll compressor. The compressor has a housing 6 installed on the base 1, the middle part of one side of the housing is provided with an inlet pipe 11, and the upper part of the other side is provided with an exhaust pipe 34, the motor stator 7 and the housing 6 are integrally fixed, and the main shaft The lower support 3 and the frame 22 are respectively fixed on the housing with positioning pins 2 and then welded. The main eccentric shaft 9 is respectively connected to the lower support 3 and the machine through the lower bearing 4, the retaining ring 5 for the shaft, the upper bearing 18 and the main bearing 19. Frame 22 and moving disk 23 are fixed, and balance weight 10 is housed on the main eccentric shaft 9. The moving disc 23 and the static disc 21 of the double function equation profile mesh with each other. The main features of this example are: 1) There are three eccentric swing shafts 15 on the...

Embodiment 2

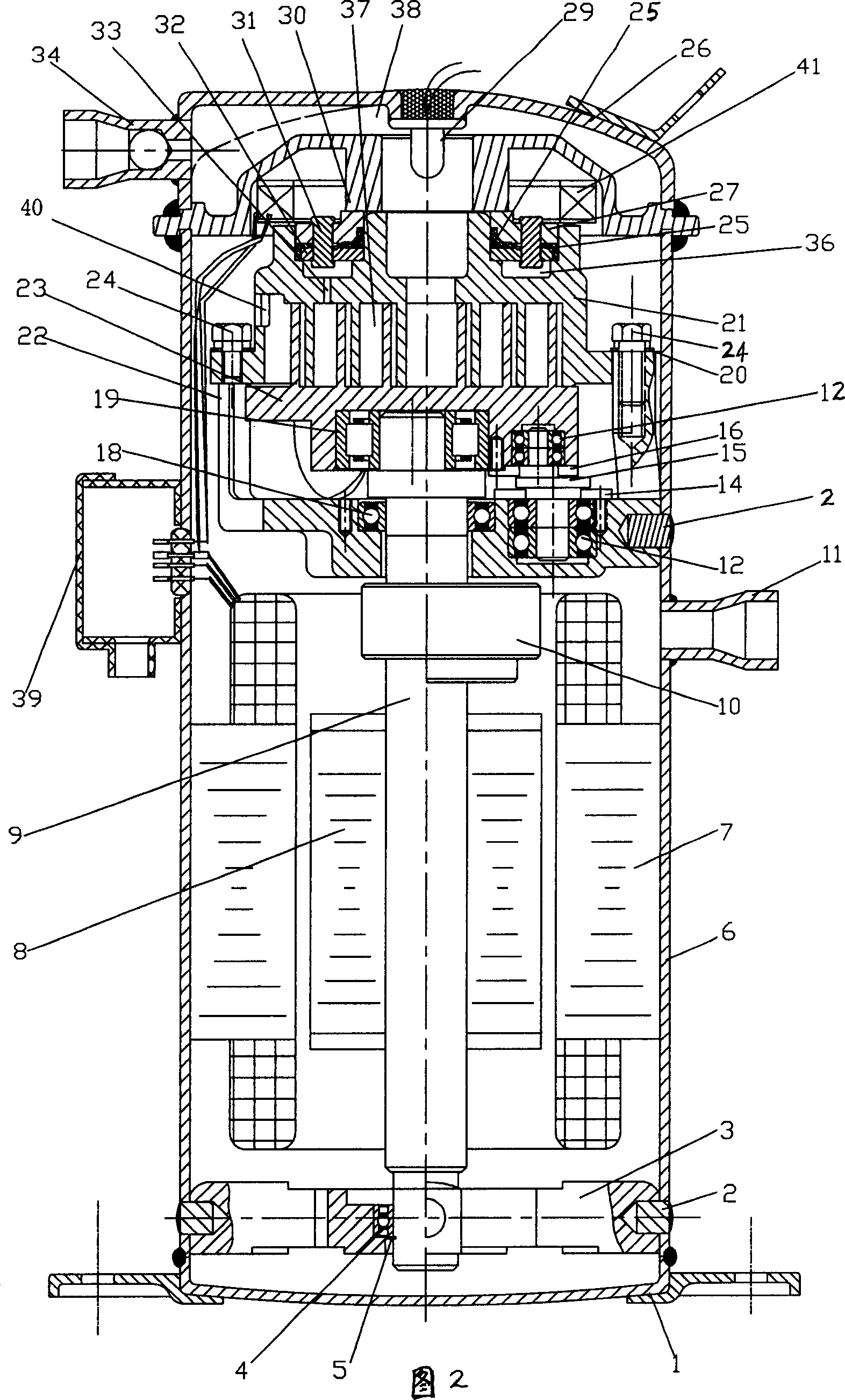

[0020] Embodiment 2, Fig. 2 is a 3HP fully enclosed oil-free digital scroll air conditioner compressor. The digital scroll compressor is a variable capacity scroll compressor, an energy-saving scroll compressor that can adjust the compression capacity according to the change of the cooling load. The oil-free design structure of the digital scroll is the same as the example 1, and the difference from the example 1 is that an electromagnet 41 is installed on the back of the static plate 21, and the electromagnet is controlled by an external control circuit. The distance between the moving discs 23 forms two working states of unloading and loading. Through the change of the time ratio of switching between the two working conditions of unloading and loading, the compressor can meet the operation requirements of different cooling loads and achieve the purpose of energy saving. After adopting oil-free, the fully enclosed oil-free digital scroll air-conditioning compressor has no lim...

Embodiment 3

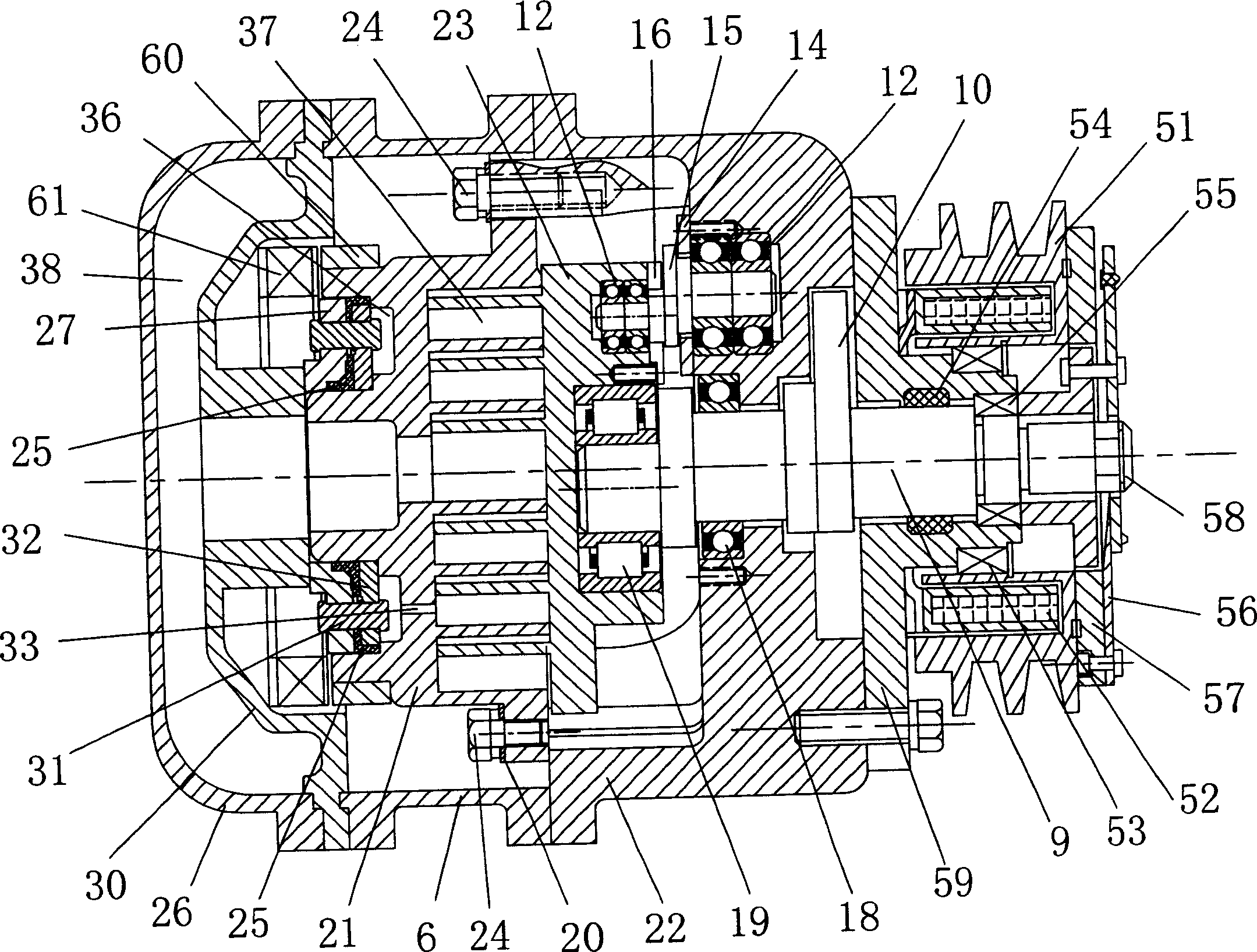

[0021] Example 3, image 3 It is an open oil-free digital scroll car air-conditioning compressor. The difference between this example and the previous two examples is that the car engine is directly driven by the pulley 51, and the running speed can reach tens of thousands of revolutions at the highest. The inside of the pulley 51 is equipped with an electromagnetic coil 52, a pulley bearing 53, and a shaft seal 54 in sequence. The main eccentric shaft 9 is equipped with a main shaft and auxiliary bearing 55. The end of the main eccentric shaft is equipped with a friction plate 57, a spring plate 56 and a spring. sheet nut 58. The back of static disc 21 is equipped with suction device 60 and electromagnet 61. Due to the oil-free design of the machine, the blockage of valve parts and pipelines will no longer occur. The use of digital control can well ensure the stability of the cooling capacity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com