Lamp string manufacturing method

A manufacturing method and technology for light strings, which are applied in special patterns, patterns characterized by light projection effects, decorative arts, etc., can solve the problems of high cost, cumbersome welding, more lamps and fewer heads, etc., and reduce the cost of processing and processing. The effect of high production efficiency and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail through the embodiments below in conjunction with the accompanying drawings.

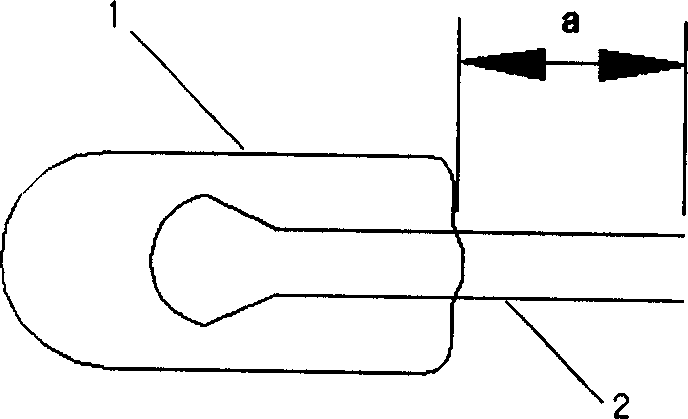

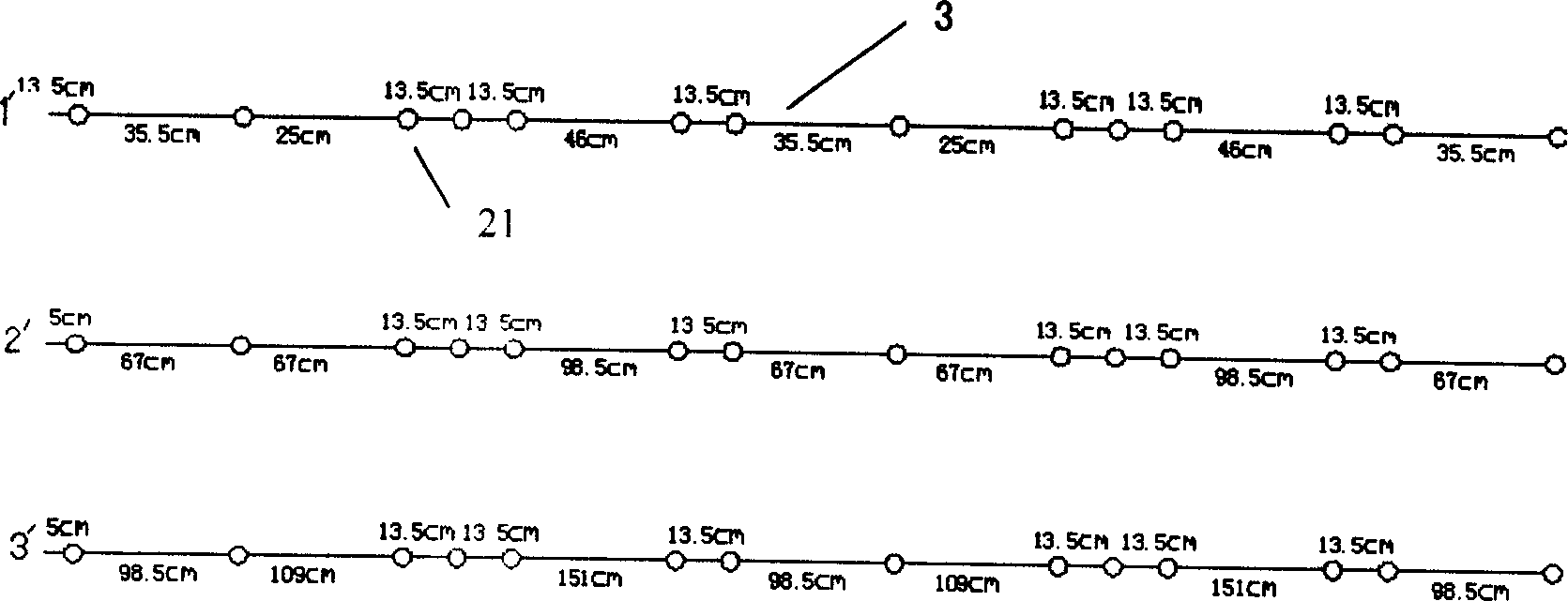

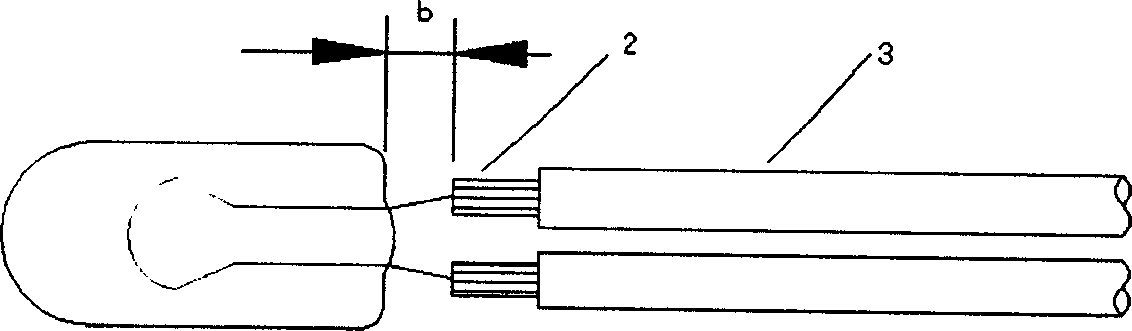

[0036] The light bulbs used in the process of manufacturing light strings in the present invention are ordinary light bulbs. The light bulb 1 for making light strings is a semi-finished light bulb without a lamp cap. The first step is to cut the lamp pins 2 and weld them in series. First, cut the lamp pins short. Keep the distance between the lamp pins as a, the value of a is 4.5±0.5mm, see figure 1 ;Then use the welding terminal line 21 of different lengths and connecting wire 3 to be welded into the bulb string 1 ' 2 ' 3 ' that 15 lamps of three kinds of different lengths form, two ends stay lamp foot, the bulb that is welded on every string bulb string Spacing such as figure 2 As shown, the distance between the bulbs in the actual processing process can be adjusted accordingly according to the site. After soldering, align the bul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com