Normal temperature cured organic polysiloxane composition

A polysiloxane and room temperature curing technology, which is applied in the field of room temperature curable organopolysiloxane compositions, can solve the problems of reducing catalysts and failing to obtain sufficient mechanical properties, and achieve the effect of long operating life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

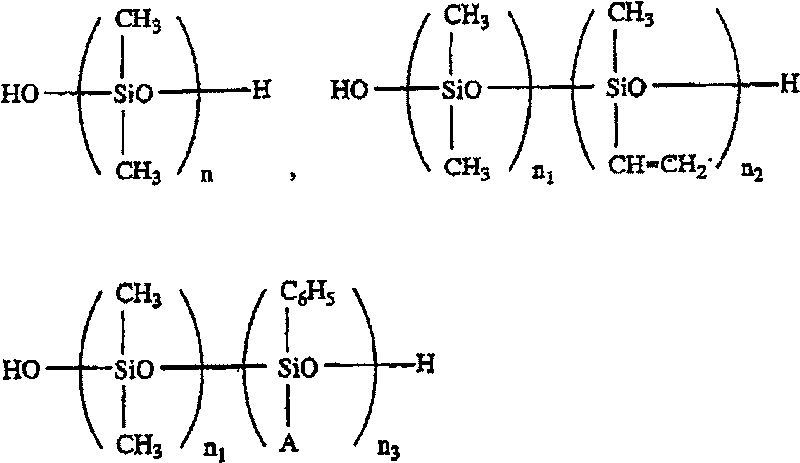

Method used

Image

Examples

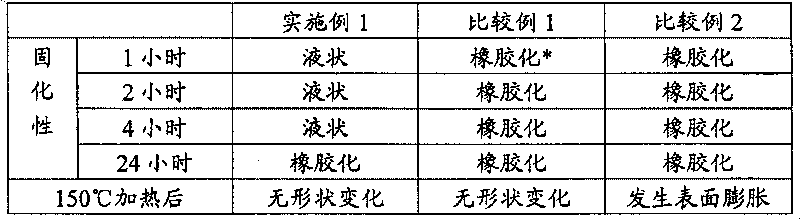

Embodiment 1

[0077] 100 parts by mass of dimethylpolysiloxane with a viscosity of 700 mPa·s terminated with hydroxyl groups at both ends, and 25 parts by mass of dimethyl polysiloxane with a viscosity of 900 mPa·s terminated with trimethoxysilyl groups through siloxane bonds. Add 0.2 parts by mass of tin dioctoate to the base polysiloxane, mix until uniform, and prepare composition 1.

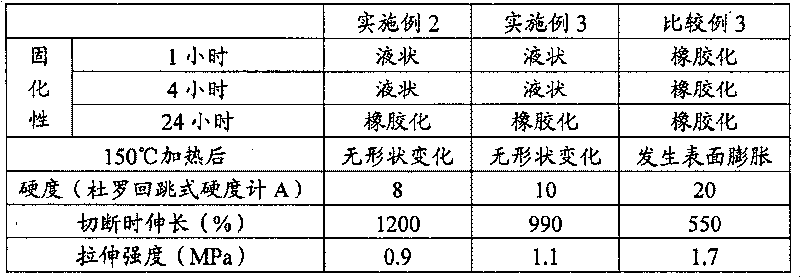

Embodiment 2

[0087] 35 parts by mass of dimethyl polysiloxane with a viscosity of 50,000 mPa·s terminated with hydroxyl groups, 40 parts by mass of colloidal calcium carbonate, and 25 parts by mass of both ends with a viscosity of 100 mPa·s terminated with a trimethylsiloxane group. s of dimethyl polysiloxane, 10 mass parts of dimethyl polysiloxane with a viscosity of 900 mPa·s whose two ends are terminated by trimethoxysilane groups through siloxane bonds, and 0.2 mass parts of tin dioctoate , and mix until uniform to prepare composition 4.

Embodiment 3

[0089] In Example 2, Composition 5 was prepared in the same manner as in Example 2, except that 1 part by mass of dioctyltin dilaurate was used instead of 0.2 parts by mass of tin dioctoate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com