Intelligent automobile and railway

A smart car and railway technology, applied to motor vehicles, rail and road dual-purpose vehicles, transportation and packaging, etc., can solve the problems of reduced driving power and fuel consumption, increased driving safety distance, increased braking distance, etc., to achieve safety Effects of shortened braking distance, improved vehicle speed and safety, and increased traffic density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

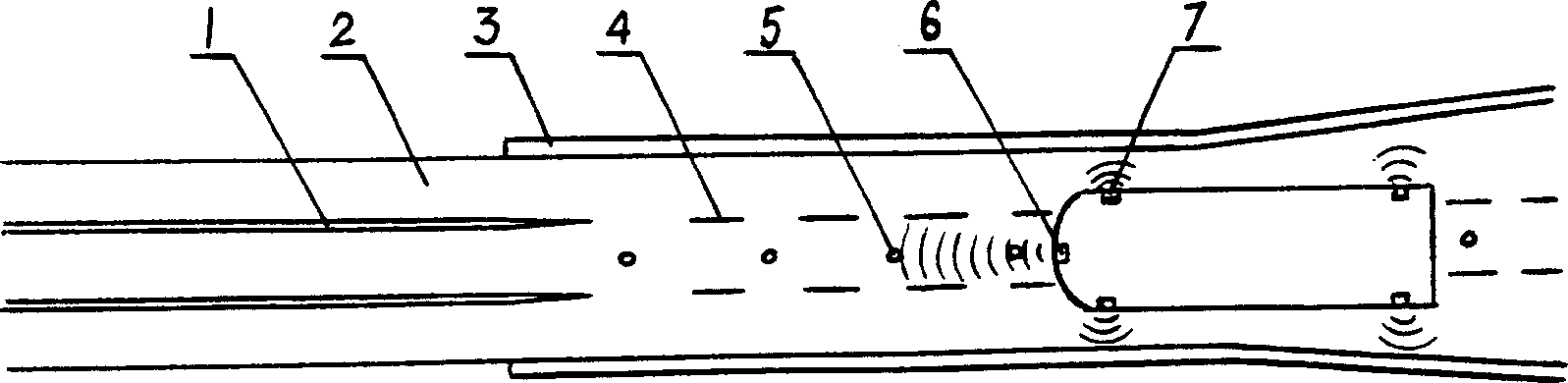

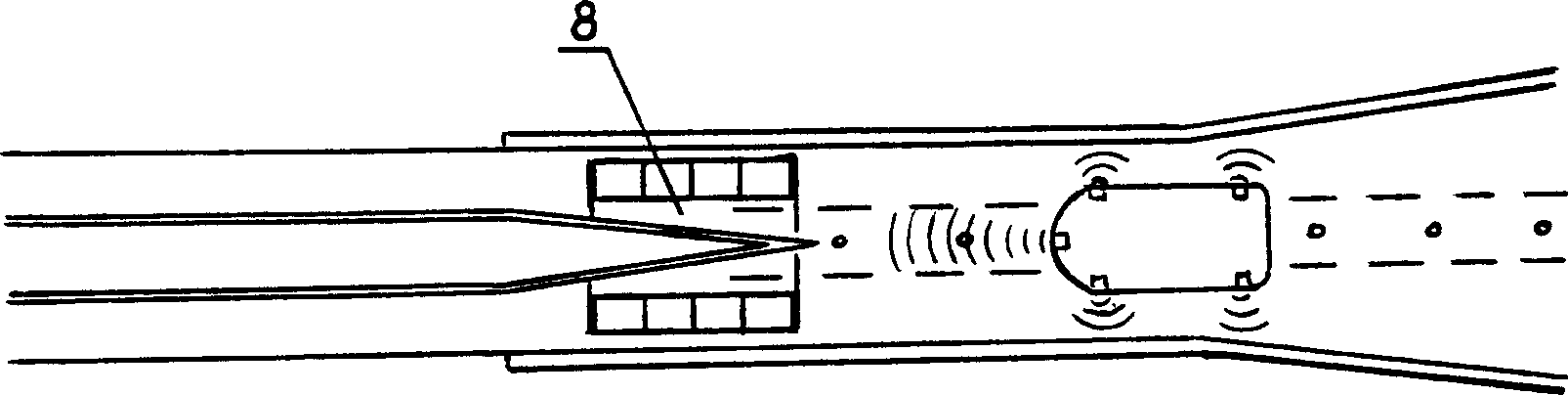

[0033] figure 1 As shown in , the rail 1 in the line is laid on the road surface 2 where the rubber wheels run, the guiding road section is located at the front end of the line, the guiding wall 3 is set on both sides, the guiding marking line 4 and the guiding magnetic nail 5 are set on the road surface, and the vehicle is guided into the road by the guiding wall. To guide the road section, the vehicle-mounted left and right distance sensors 7 measure the guide wall to determine the lateral position of the vehicle in the road section; The lateral relative position of the vehicle in the guiding road section, through the steering control device installed on the vehicle steering system, controls the steering wheel, so that the vehicle travels on the center line of the guiding road section, ensuring that the vehicle is aligned with the line and the steel wheel smoothly drives onto the rail; The vehicle is guided by steel wheels and driven by rubber wheels, both of which jointly c...

Embodiment 2

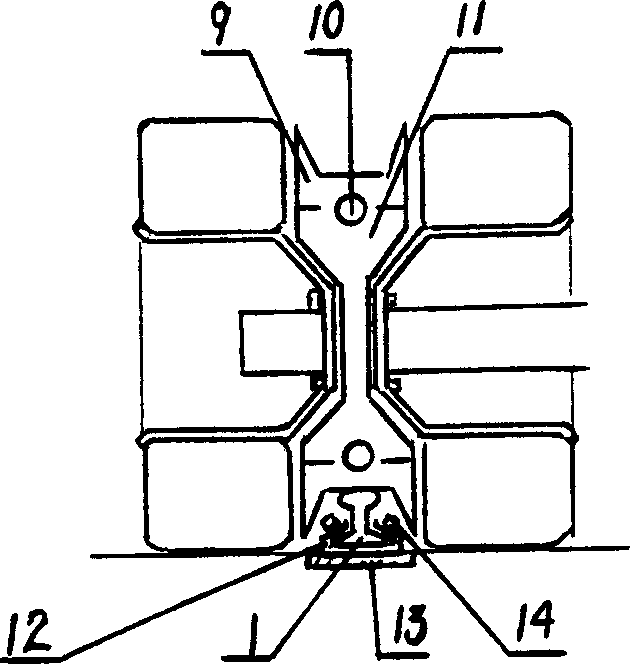

[0038] figure 2 As shown in , the steel wheel 9 is installed on the wheel core 11 through the axle disc 10, and the wheel core 11 is located between two rubber wheels or is installed on one side of the steel ring of the rubber wheel (see diagram 2-1 ), the rubber wheel runs on the road surface in the line, and the steel wheel runs on the top of the steel rail laid on the road surface; 14 adjustment fixed. The weight of the vehicle is carried by the steel wheel and the rubber wheel at the same time, and is driven by the steel wheel guiding the rubber wheel.

[0039] Figure 3 and Figure 4 As shown, the steel wheel 9 is installed below the chassis of the compartment or the frame of a large vehicle (see Pic 4-1 ), run on the rails laid above the track slab 15, and run on the rubber wheels on the road to jointly carry the weight of the vehicle. In the application, the small car line can be laid separately (see Fig. 3), also can unify steel wheel track and gauge with large c...

Embodiment 3

[0042] see Figure 6 , in the application, a hydraulic device can be installed on the steel wheel to adjust the pressure between the steel wheel and the rail, thereby adjusting the weight of the vehicle carried by the steel wheel, so that the weight of the vehicle carried between the steel wheel and the rubber wheel can be adjusted according to The operating status of the vehicle is assigned. As shown in the figure, the steel wheel 9 is located in the slide frame 20, the slide frame 20 is installed on the guide rod 19 in the wheel frame 18 through the axle sleeves at its two ends, and the push plate 23 installed on the guide rod 19 through the slide sleeve is positioned on the slide frame. Frame 20 tops, hydraulic cylinder 22 is established between the two, and air spring 21 is established between push plate 23 and the wheel frame 18 above, and return spring 21 is established under slide frame 20 and guide rod 19 simultaneously. When the vehicle starts and accelerates, the hy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com