Interlayer insulating layer for printed wiring board, printed wiring board and method for manufacturing same

An interlayer insulating layer, printed circuit board technology, applied in the direction of multi-layer circuit manufacturing, etc., can solve the problems of inability to be used repeatedly and high price, and achieve the effect of reducing the thermal expansion coefficient and improving the thermal cycle resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0213] (A) Production of kneaded product containing scaly particles

[0214] In a mixed solvent of 20 g of methyl ethyl ketone (hereinafter referred to as "MEK") and 80 g of xylene, 15 g of scaly particles (manufactured by Hy-Jun Co., Ltd., trade name "Espen C"," added, aspect ratio during dispersion: ~500, crystal Size: ~0.5μm), kneaded with three rolls to form a kneaded product containing scaly particles.

[0215] (B) Preparation of epoxy resin solution

[0216] To a mixed solvent of 6.8 g of MEK and 27.2 g of xylene, 85 g of solid epoxy resin (manufactured by Nippon Epoxy Resins Japan Epoxy Resin Co., Ltd., trade name "Epco Eto 1007") was added and mixed to obtain an epoxy resin-containing solution.

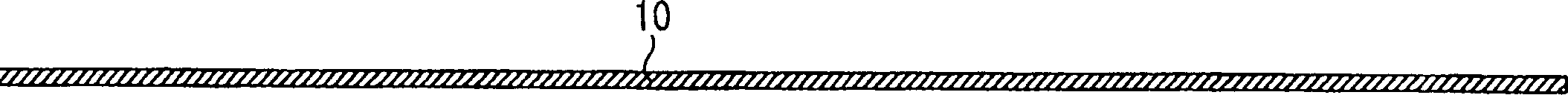

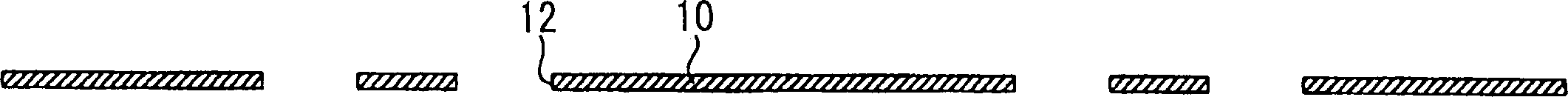

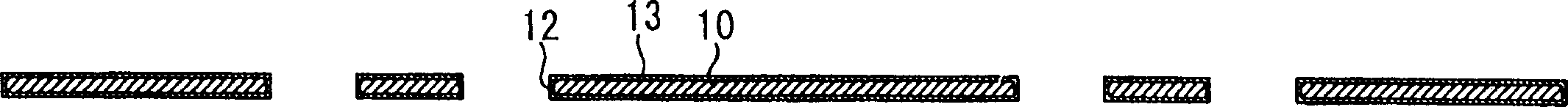

[0217] (C) Production of resin film for interlayer insulation layer

[0218] Using three rollers, the kneaded product containing scaly particles prepared in (A), the epoxy resin solution prepared in (B), and dicyandiamide (ビイ·テイ·アイ·ジヤパンProduced by the company, trade name "CG-1200"...

Embodiment 2

[0324] As the scaly particles, the trade name "NANOFIL" manufactured by Tomi-Industry Co., Ltd. (aspect ratio after dispersion: 100 to 500, particle diameter: 0.1 to 0.5 μm, minimum particle thickness: 0.001 μm) was used. In Example 1, a multilayer printed circuit board was produced in the same manner.

Embodiment 3

[0326] Except that the flaky particle-containing kneaded product and the epoxy resin-containing solution were prepared in accordance with the following (A) to (B), a multilayer printed wiring board was manufactured in the same manner as in Example 1 except that the kneaded product was prepared.

[0327] (A) Production of kneaded product containing scaly particles

[0328] In a mixed solvent of 33g of MEK and 67g of xylene, 15g of scaly particles (manufactured by Hyjyun Co., Ltd., trade name "Espen C", aspect ratio during dispersion: ~500, crystal size: ~0.5μm) was added, and Three rolls are kneaded to form a kneaded product containing scaly particles.

[0329] (B) Preparation of epoxy resin solution

[0330] To a mixed solvent of MEK11g and 23g xylene, 85g of solid epoxy resin (manufactured by Nippon Epoxy Resins Japan Epoxy Resin Co., Ltd., trade name "Epco Eto 1007") was added and mixed to obtain a solution containing epoxy resin .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average length | aaaaa | aaaaa |

| Average width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com