Production and producer for nanometer ferric oxide

A technology of nano-iron oxide and oxygen, applied in the direction of iron oxide, ferrous oxide, iron oxide/iron hydroxide, etc., can solve the problems of complex process, large particle size, poor quality, etc., and achieve simple process, good product quality, The effect of high tinting strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

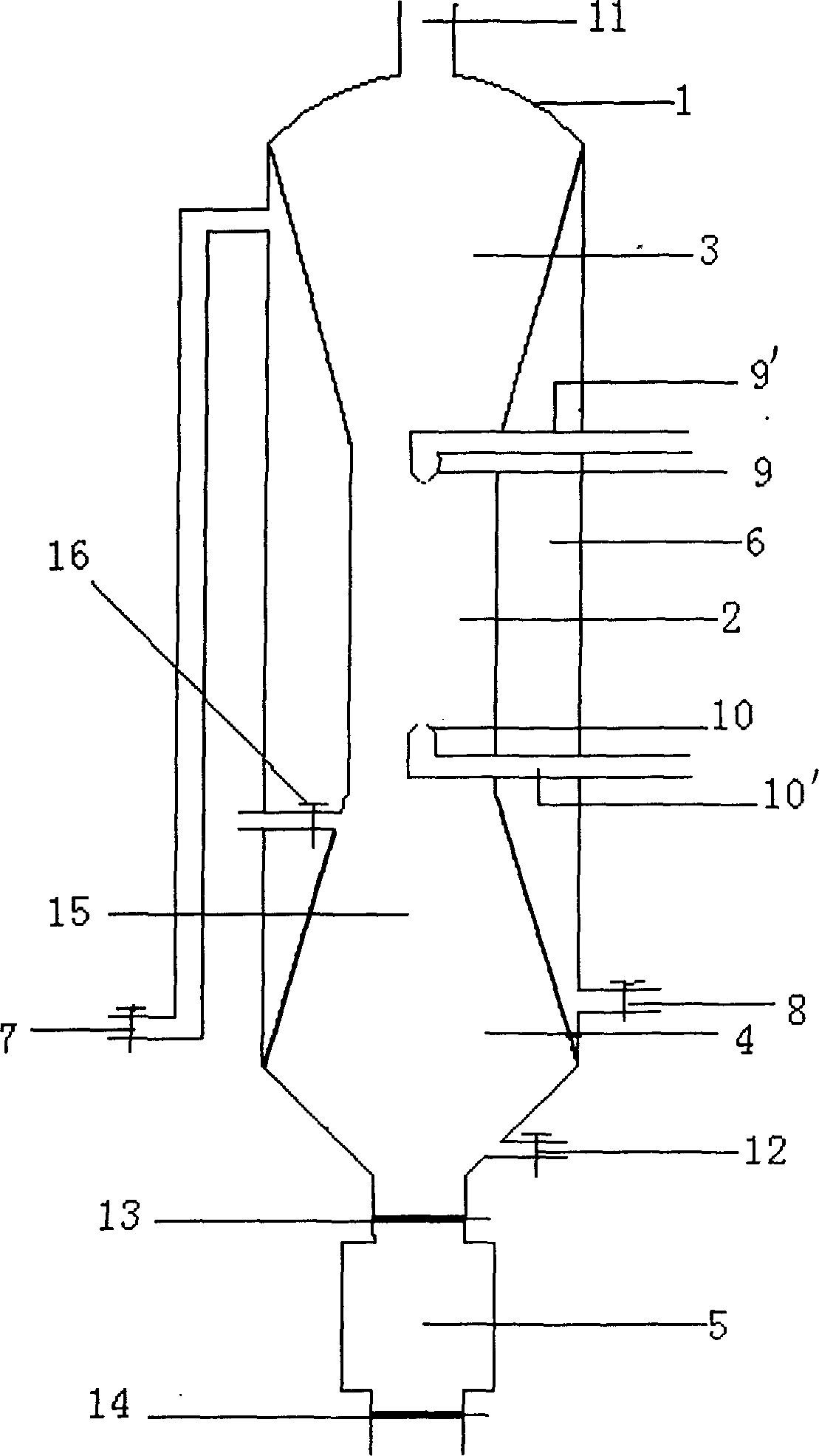

[0021] The present invention will be further described below in conjunction with the drawings and embodiments.

[0022] In the equipment of the present invention, the reactor 1 includes a combustion chamber 2, a settling chamber 4, a receiver 5, and a dust chamber 3. The cooling chamber 6 surrounds the outside of the reactor 1, and has inlet and outlet valves 7 and 8 on it.

[0023] The combustion chamber 2 is provided with two pipes extending out of the reactor 1, namely the raw material spray pipe 9'and the gas pipe 10'. They are placed in the combustion chamber 2 at one end of the port with nozzles 9, 10 respectively for pentacarbonyl Iron and oxygen or air undergo combustion reaction, the nozzle 10 with oxygen or air is placed in the lower part of the combustion chamber 2 and sprays upward, and the nozzle 9 with pentacarbonyl iron is placed in the upper part of the combustion chamber 2 and sprays downward;

[0024] The sedimentation chamber 4 is located at the lower part of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com