Drum-style drill for sowing-disk base material

A drum type, matrix technology, applied in the direction of excavation/covering trenches, application, planting methods, etc., can solve the problems of precise positioning, high cost, difficult control, etc., and achieves the effect of good versatility and flexible and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

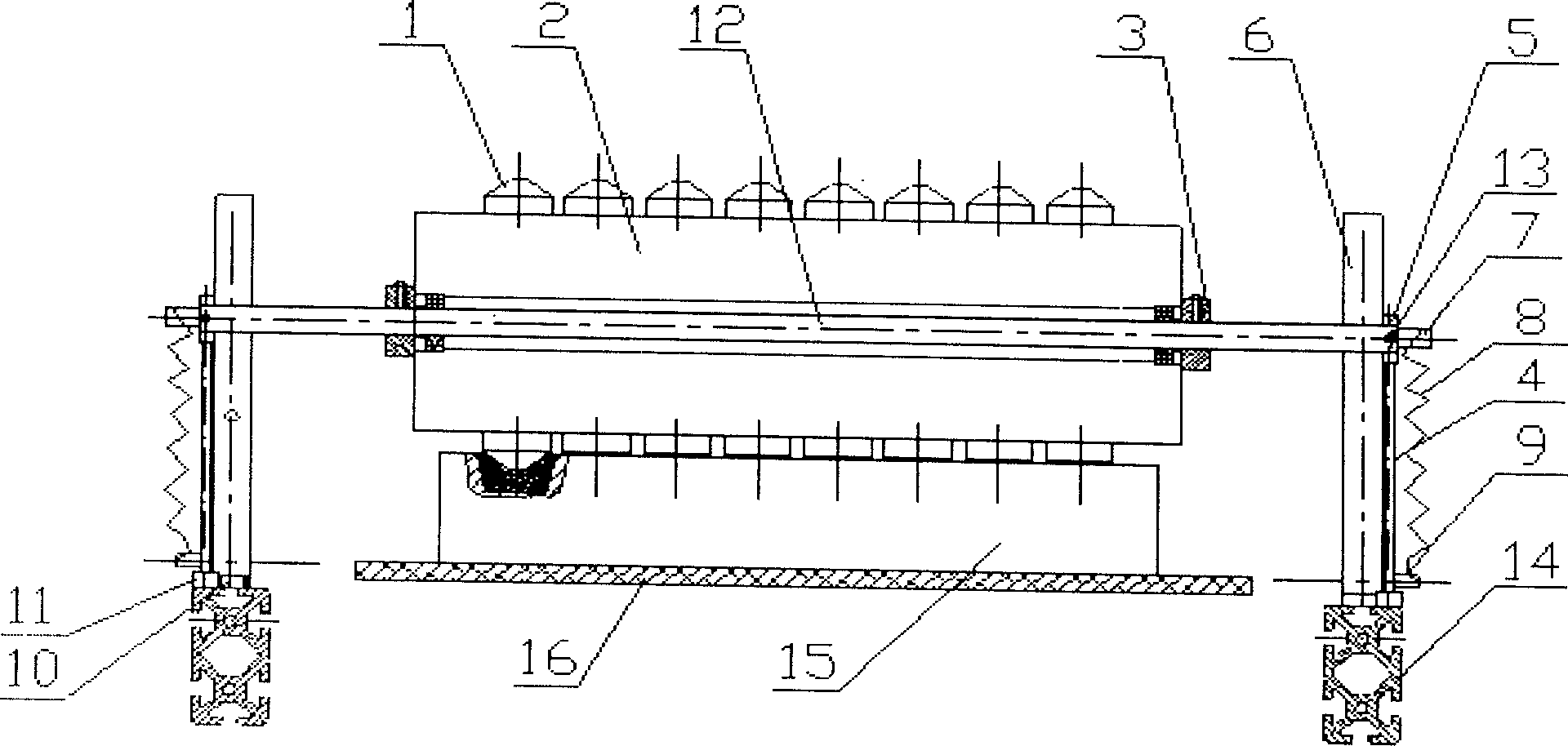

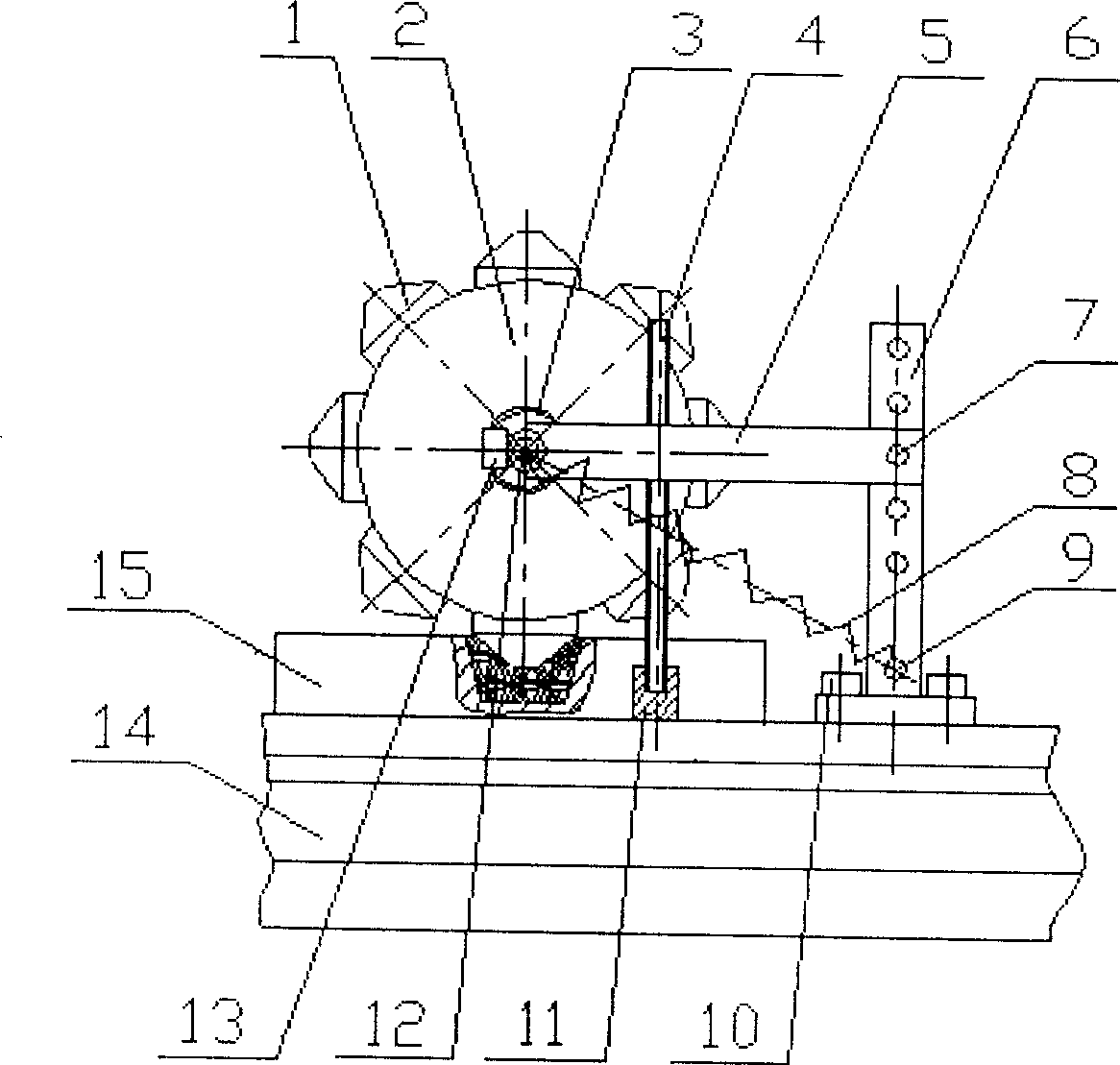

[0011] Such as figure 1 , figure 2 As shown, the hole plate matrix roller type hole punching device includes two adjustment supports 6 fixed on the sowing support 14 by screws 10, and a cross bar 5 is connected to each of the two adjustment supports 6 through two rotating shafts 7. A crossbar 5 is provided with a drum rotating shaft 12, on which the drum rotating shaft 12 is provided with a drum 2 that is all covered with a conical punching head 1, and two drum rotating shaft stoppers 3 for fixing the drum rotating shaft, and the drum rotating shaft is fixed by screws 13 On the cross bar 5, a spring 8 is connected to the spring pin 9 of the adjustment support 6 at both ends of the drum rotating shaft 12 and the adjustment rod 4 and pad 11 for adjusting the height of the drum 2 .

[0012] The whole working process of the tray matrix roller type hole punching device of the present invention is as follows: the tray 15 advances under the drive of the conveyor belt 16, and when i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com