Co-axial middle-set motor driving device of electric vehicle

A mid-mounted motor and driving device technology, applied in electric vehicles, electromechanical devices, motors, etc., can solve problems such as unreasonable center of gravity, poor reliability, and short mileage, and achieve reasonable center of gravity, fast starting speed, and output torque big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

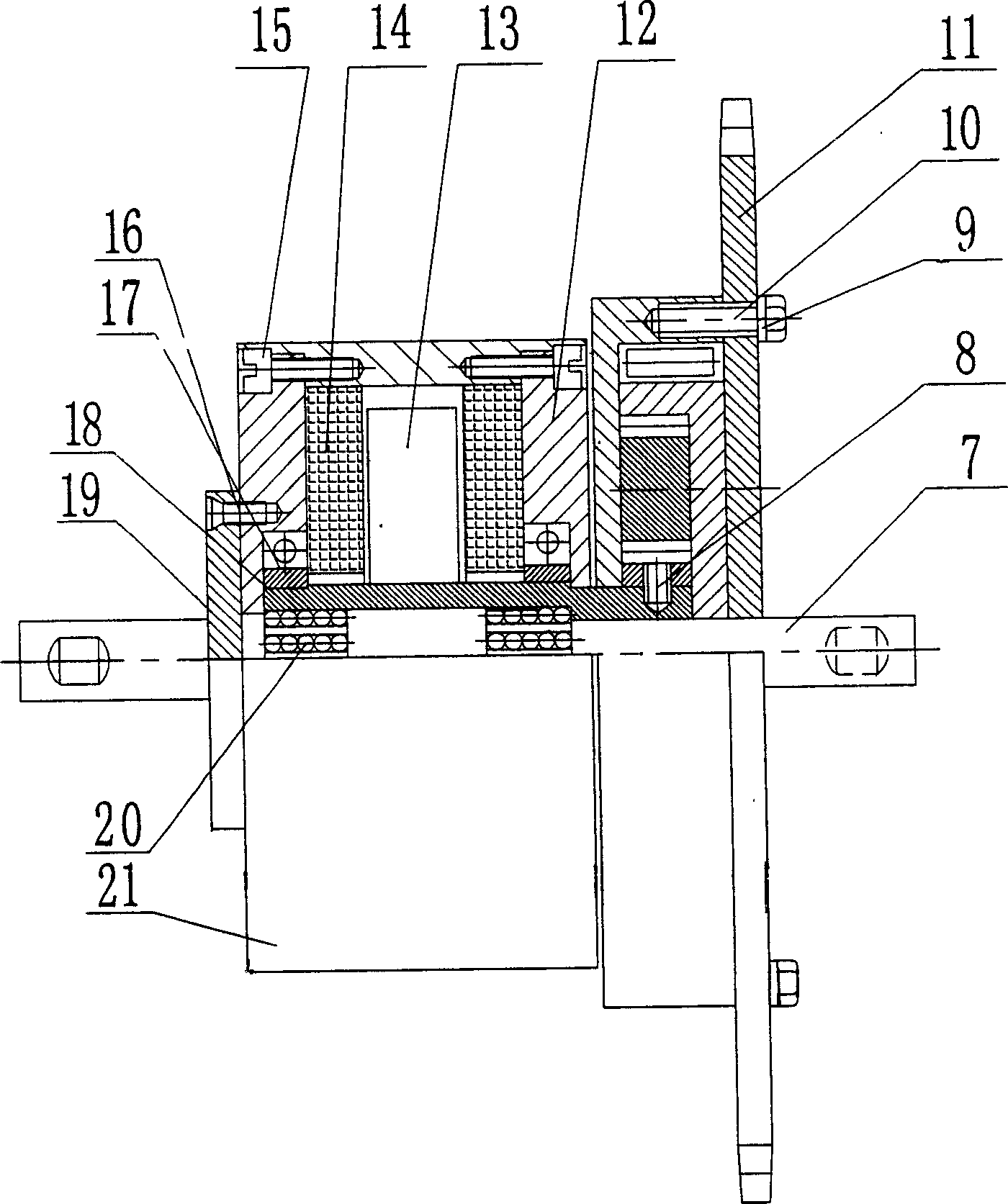

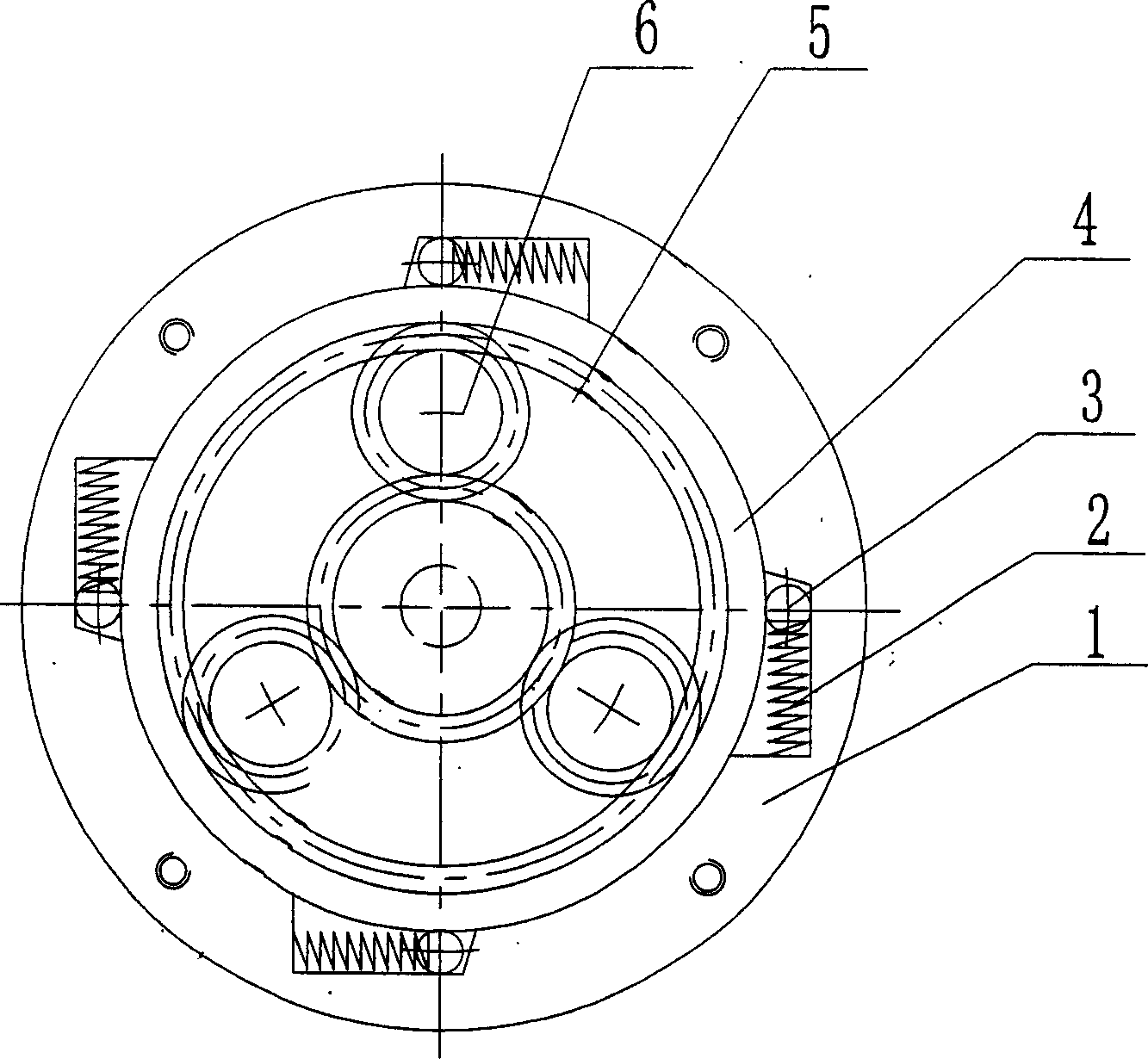

[0014] Such as figure 1 As shown, what this embodiment adopts is a brushless motor. The left half is the motor drive mechanism, and the right half is the variable speed clutch mechanism. Pedal is installed in the two ends of central shaft 7, and central shaft 7 is installed in the axle position of vehicle frame by bearing. The hollow shaft 18 is concentric with the central shaft 7 for the rotor shaft of the motor. It is installed on the central shaft 7 through two sets of multi-row steel balls 20, the rotor permanent magnet 13 is fixed in the middle of the hollow shaft 18, the coils 14 on both sides of the rotor are fixed in the inner cavity of the motor casing 21, and the casing 21 passes through two bearings 17 Fixed on both ends of the hollow shaft 18. When the coil 14 supplies power, the rotor permanent magnet 13 rotates under the action of the magnetic force line and drives the hollow shaft 18 to rotate around the central axis 7 at a high speed, and the power is driven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com