Plasma display panel and method producing same

A display panel, plasma technology, applied in the direction of alternating current plasma display panel, cold cathode manufacturing, electrode system manufacturing, etc., can solve the problems of increased processing time, increased manufacturing cost, decreased productivity, etc., to prevent alignment errors, improve productivity, The effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0042] image 3 The structure of the PDP according to the first embodiment of the present invention is illustrated.

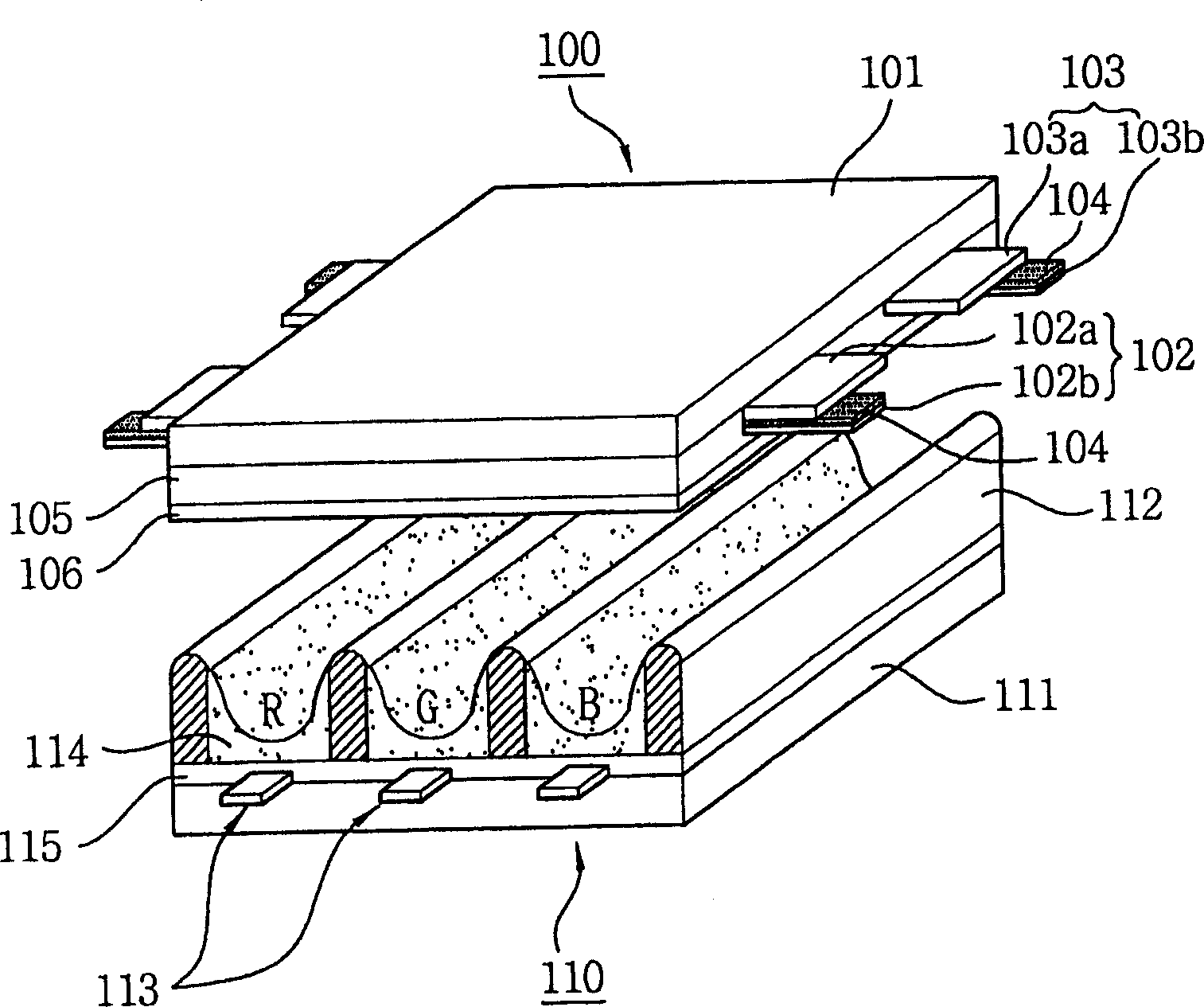

[0043] refer to image 3 , in the PDP according to the first embodiment of the present invention, the front panel 300 and the rear panel 310 are combined with each other and run parallel to each other at uniform intervals, wherein by arranging a plurality of pairs of scan electrodes 302 and sustain electrodes 303 The front panel 300 is obtained by sustain electrode pairs, and the rear panel 310 is obtained by arranging a plurality of address electrodes 313 to cross the plurality of sustain electrode pairs.

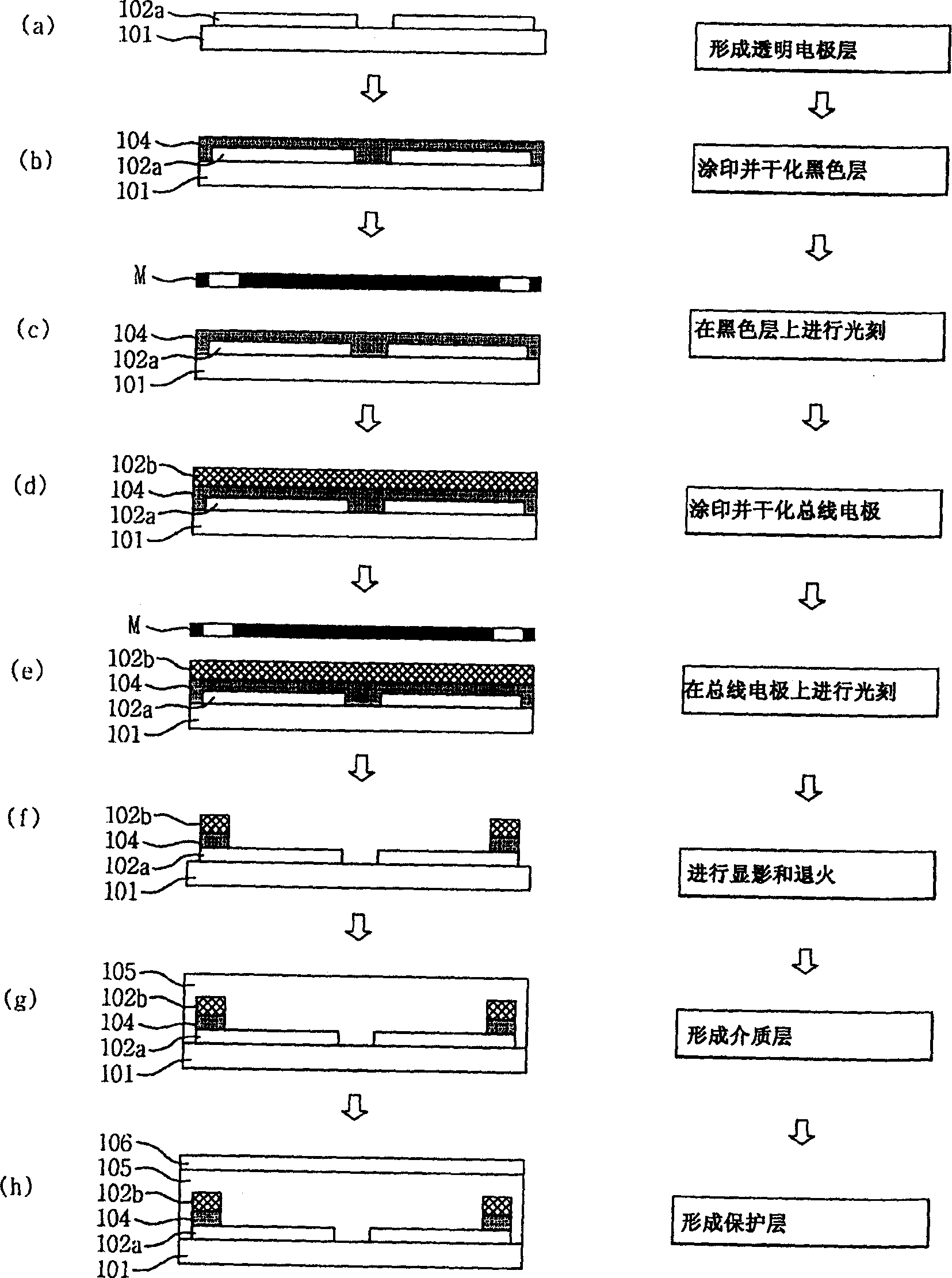

[0044] In the front panel 300, a scan electrode 302 and a sustain electrode 303 are formed on a front glass 301, which are used to mutually discharge within one cell to sustain emission of the cell. The scan electrodes 302 and the sustain electrodes 303 include transparent electrodes 302a and 303a made of a transparent material, and bus electrodes 302b an...

no. 2 example

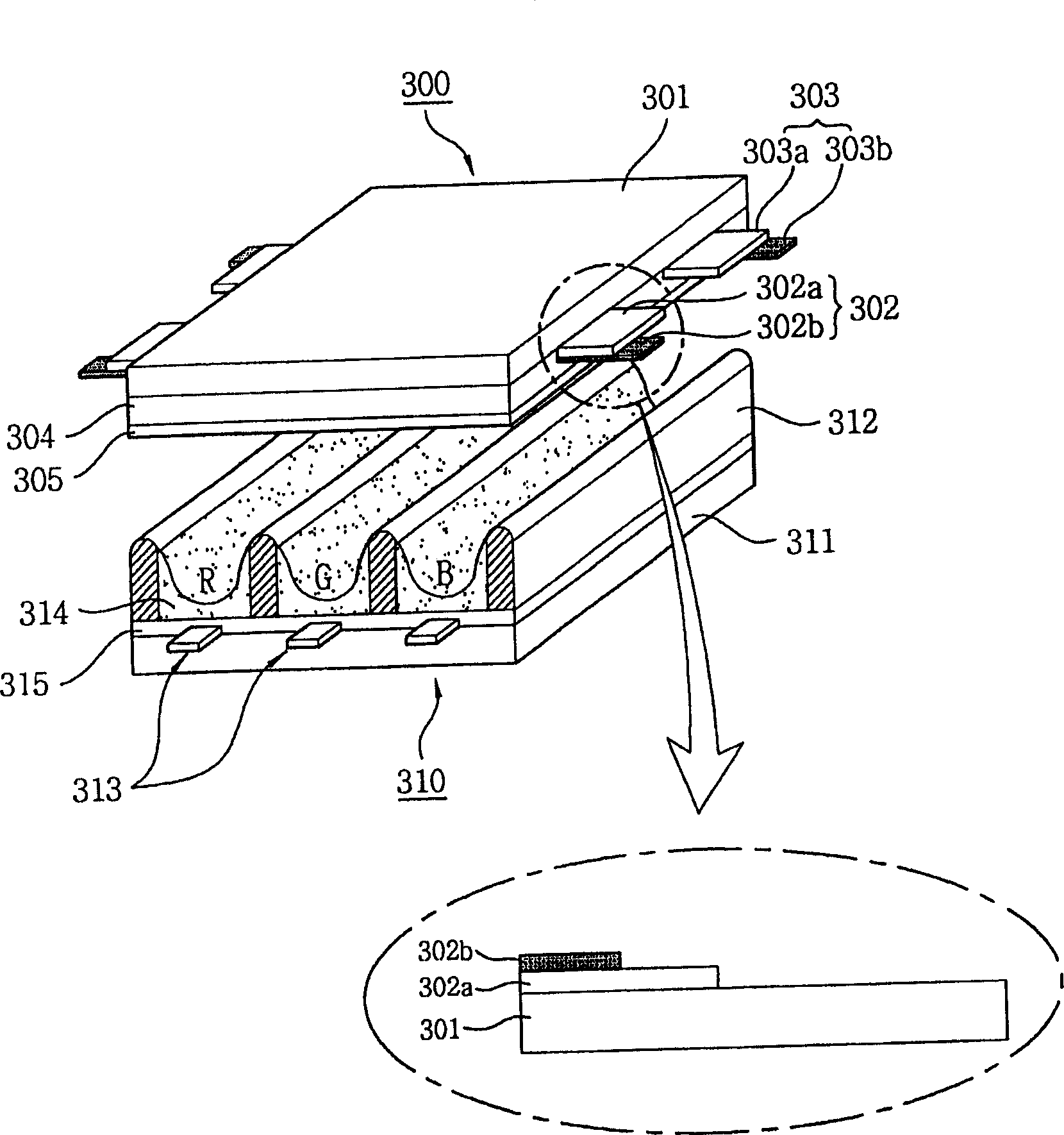

[0072] Figure 6 The structure of the PDP according to the second embodiment of the present invention is illustrated.

[0073] refer to Figure 6 , the structure of the PDP according to the second embodiment of the present invention is almost the same as that according to the first embodiment of the present invention. Therefore, a description of its structure which is the same as that of the PDP according to the first embodiment of the present invention will be omitted. In the PDP according to the second embodiment of the present invention, scan electrodes 402 and sustain electrodes 403 do not include transparent electrodes but include only bus electrodes 402b and 403b.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com