Brake assembly, particularly for a hydraulic wheel drive

A driving device and hydraulic wheel technology, applied in the directions of brake actuators, brake components, brake types, etc., can solve the problems of system redundancy, problems, and can no longer guarantee the brake function, and save design space and space. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

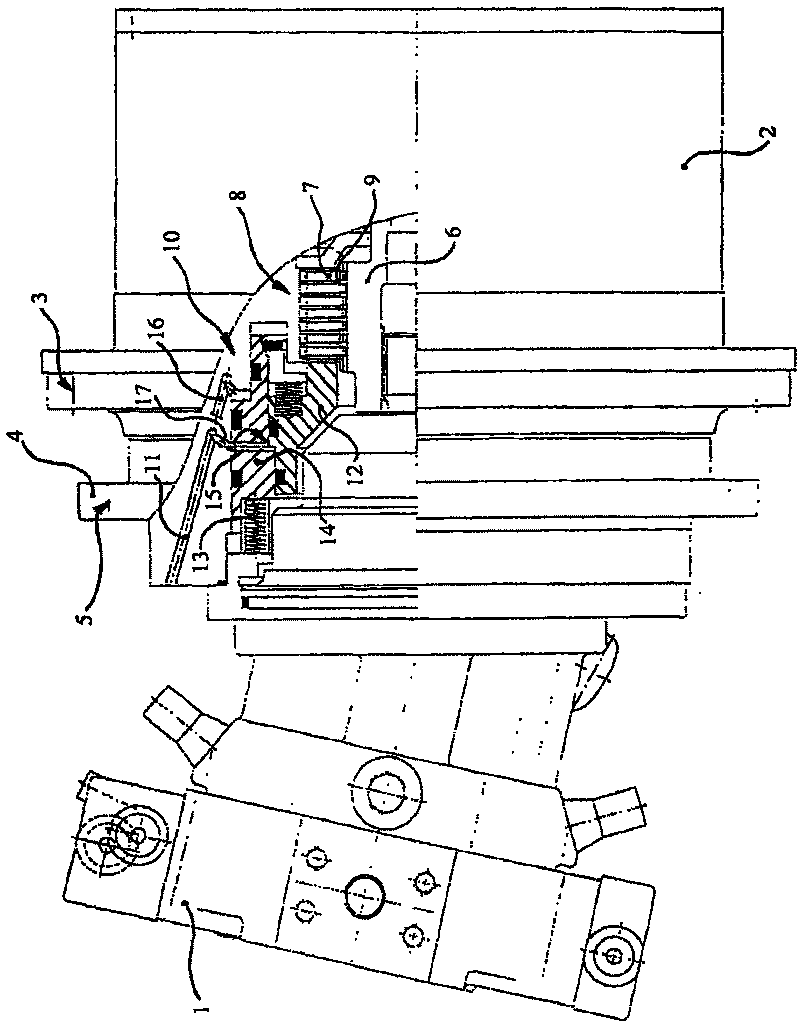

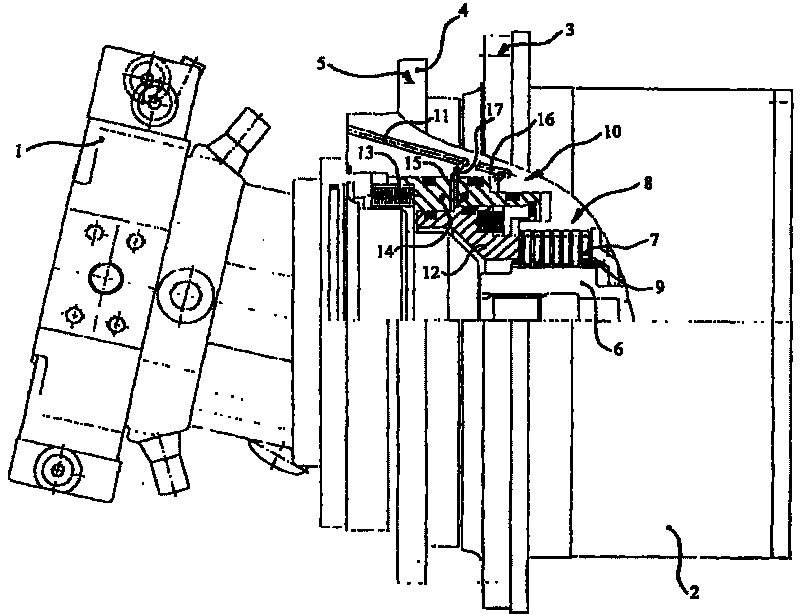

[0017] The wheel drive essentially consists of a hydraulic motor 1 which is flanged to a planetary gearbox 2 and whose housing is provided with holes 3 for the connection of a motor vehicle wheel (not further shown in the figures). The wheel drive further comprises a support shaft 4, through an outer radial hole 5 of the support shaft, the entire wheel drive is mounted on a motor vehicle (not further shown in the figures).

[0018] The inner disk 7 of the disk pack 8 is arranged on the drive side of the planetary gearbox 2 on the drive shaft 6 interacting with the hydraulic motor 1 . The inner disk 7 interacts with a relatively narrow outer disk 9 of the disk package 8 , which is fixedly arranged relative to the bearing shaft 4 .

[0019] The friction plate set 8 can be braked by pressing the piston structure 10 . The piston arrangement 10 consists of a service brake piston 12 , which is pressed by a first hydraulic circuit 11 , and a parking brake piston 14 , which is presse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com