Linkage mechanism of drive-free self-adapting artificial hand

A linkage mechanism and self-adaptive technology, which is applied in the direction of manipulators, chucks, manufacturing tools, etc., can solve the problems of weak self-adaption and inability to realize linkage, etc., and achieve strong self-adaptability, overall weight reduction and stable grip Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

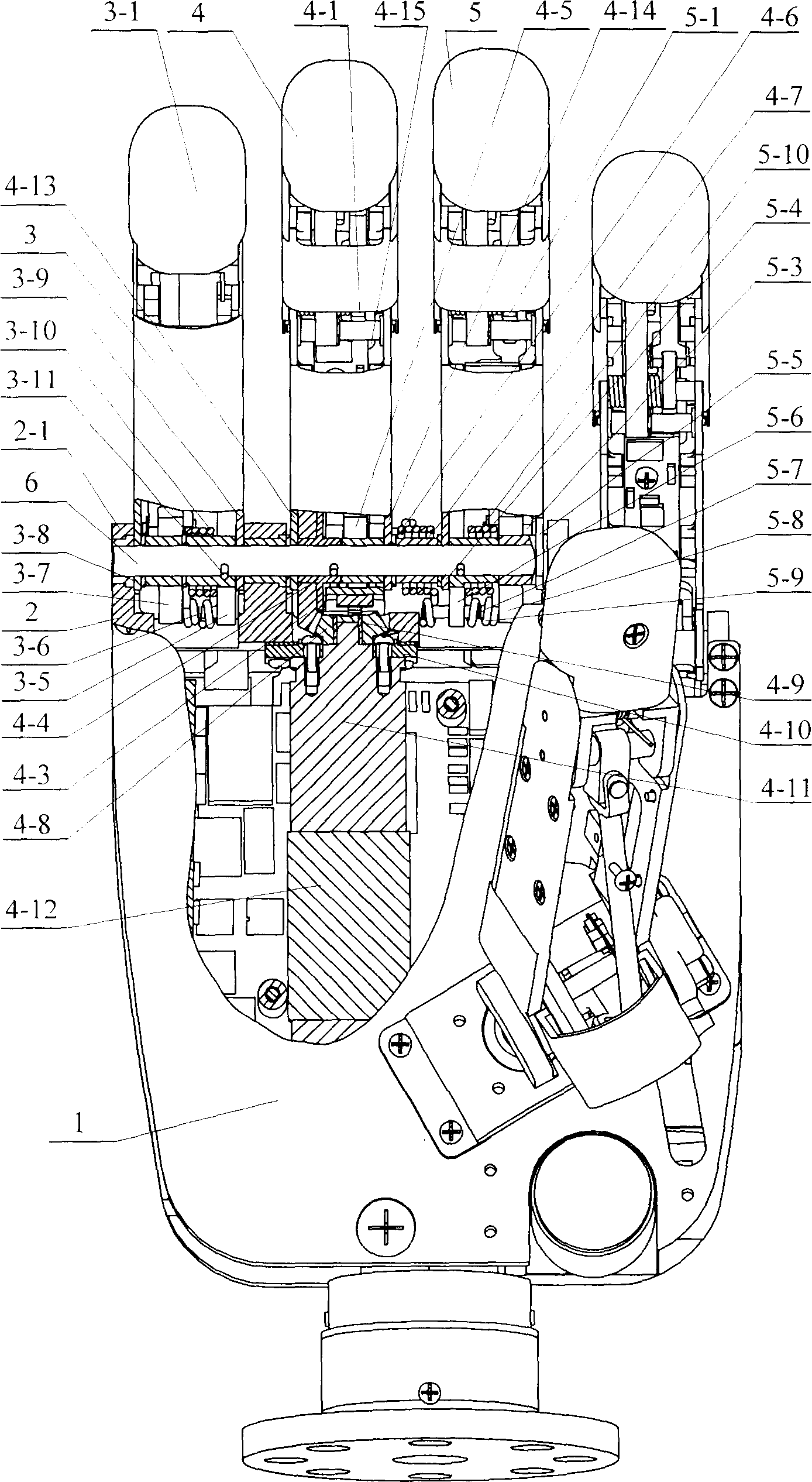

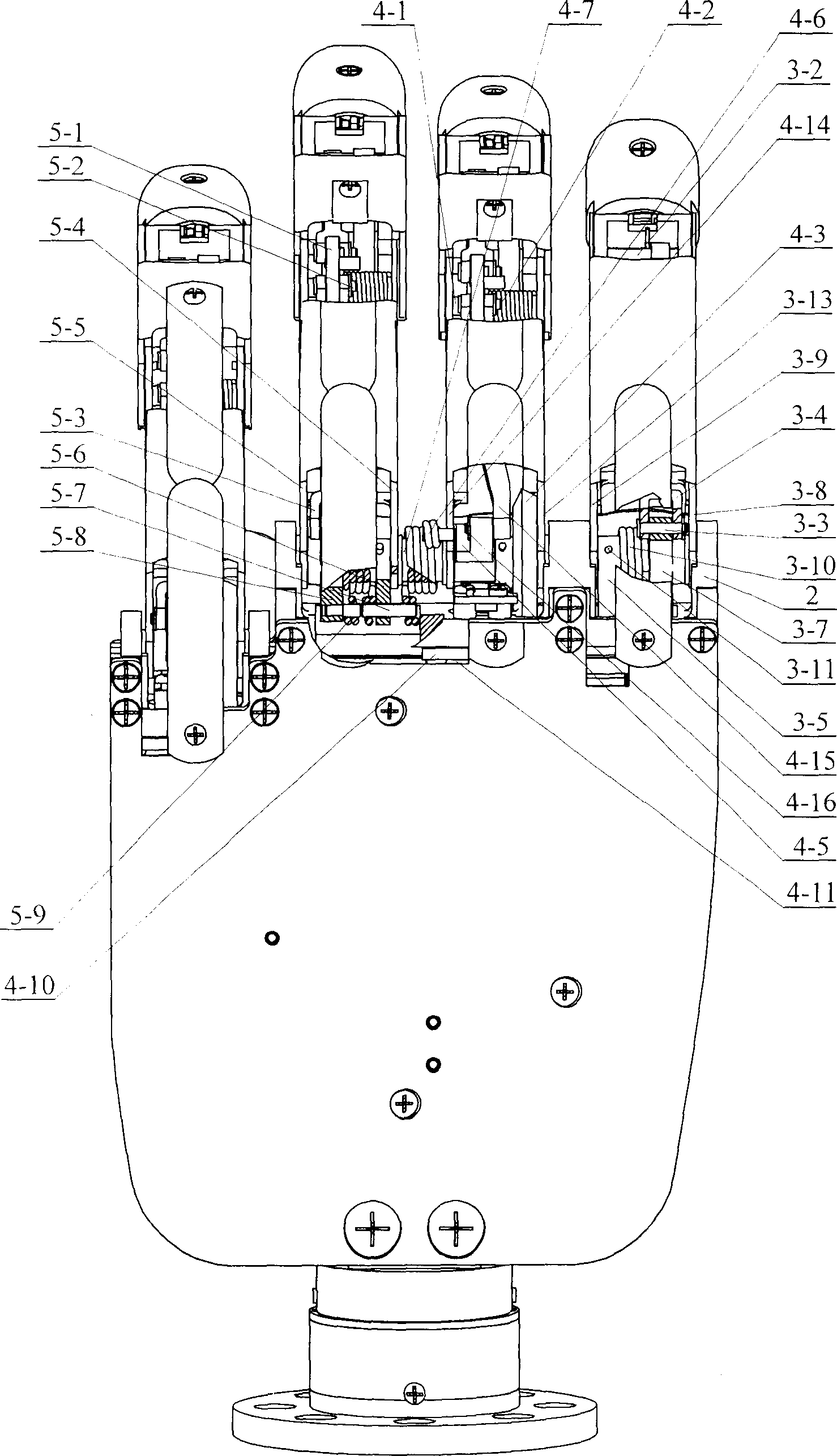

[0007] Specific implementation mode one: combine figure 1 , figure 2 Describe this embodiment, this embodiment is made up of palm 1, the base 2 that is fixedly connected with palm 1, the little finger 3 that is contained in the groove of base 2 in turn, ring finger 4 and middle finger 5, base joint shaft 6; The little finger 3 is by the little finger tip shaft 3-2 connected with the little finger tip 3-1, the little finger connecting rod pin shaft 3-3, the little finger connecting rod 3-4, the spring support 3-5, the spring stop pin 3-6 , little finger torque sensor 3-7, little finger left side plate 3-8, little finger right side plate 3-9, little finger torsion spring 3-10; described ring finger 4 is made up of the ring finger fixed on the middle joint shaft 4-1 of the ring finger Middle joint connecting rod pin 4-2, large bevel gear 4-3, large bevel gear bushing 4-4, ring finger torque sensor 4-5, ring finger torsion spring 4-6, ring finger torsion spring sleeve 4-7, small...

specific Embodiment approach 2

[0009] Specific embodiment 2: This embodiment is described in conjunction with the drawings. The difference between this embodiment and specific embodiment 1 is: the little finger 3 of this embodiment also has a spring support positioning pin 3-11; the spring support 3-5 The positioning pin 3-11 of the spring support is fixedly connected with the base joint shaft 6. The above-mentioned structure has the advantages of simple structure, safe and reliable use.

[0010]Working principle: the output shaft of the motor 4-12 drives the reducer 4-11 to rotate, the output shaft of the reducer 4-11 drives the small bevel gear 4-8 to rotate, and the small bevel gear 4-8 drives the large bevel gear 4-3 to move; The movement of the large bevel gear 4-3 drives the base joint shaft 6 to rotate through the large bevel gear bushing 4-4, thereby driving the spring support 3-5 of the middle finger 5 and the little finger 3 and the spring support 5-6 of the middle finger to move, and the spring s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com