Steel cord for rubber track main cord

A technology of rubber crawler and steel cord, which is applied to the reinforcement layer of pneumatic tires, transportation and packaging, tire parts, etc., can solve the problems of low immersion of core wire 82C, increased weight of steel cord 90, narrow gap, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

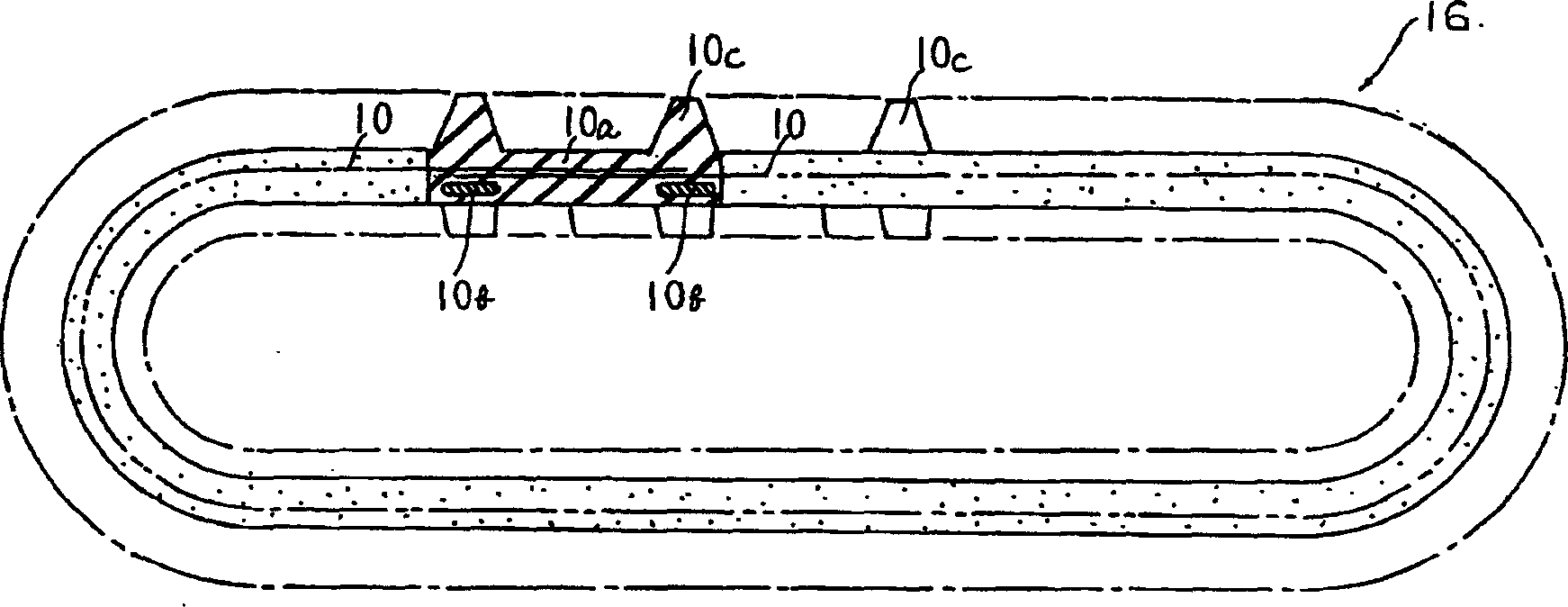

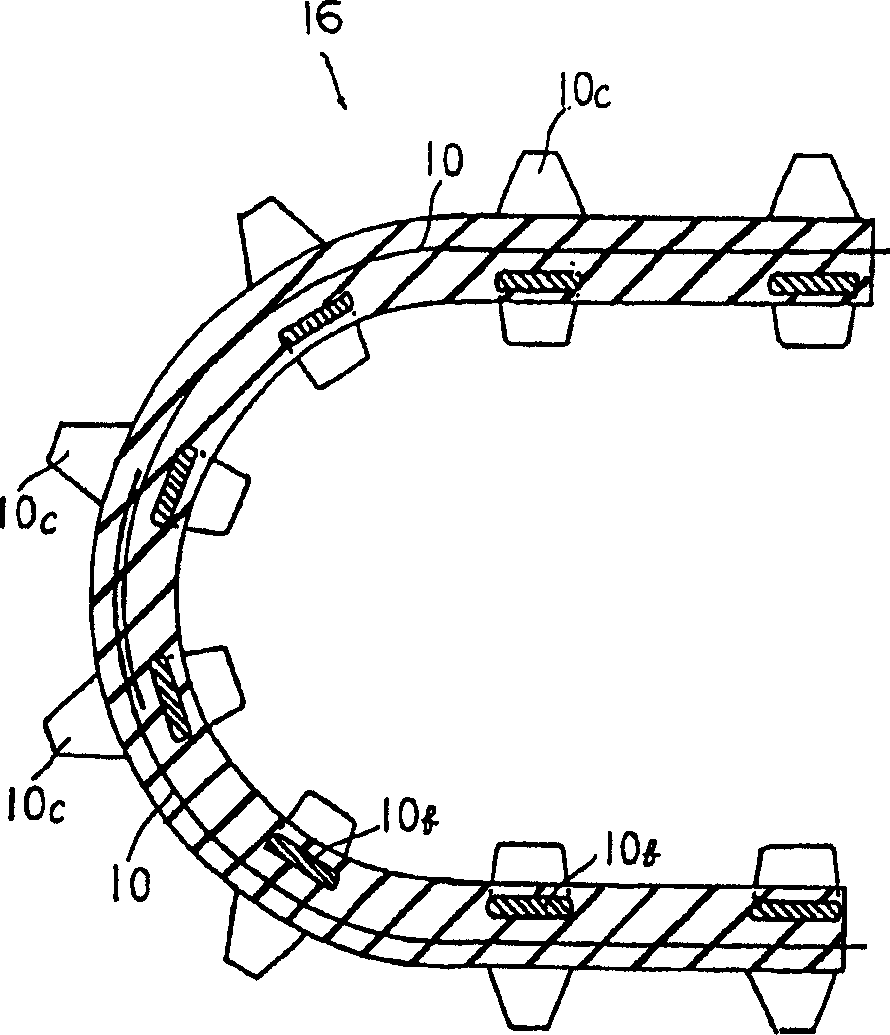

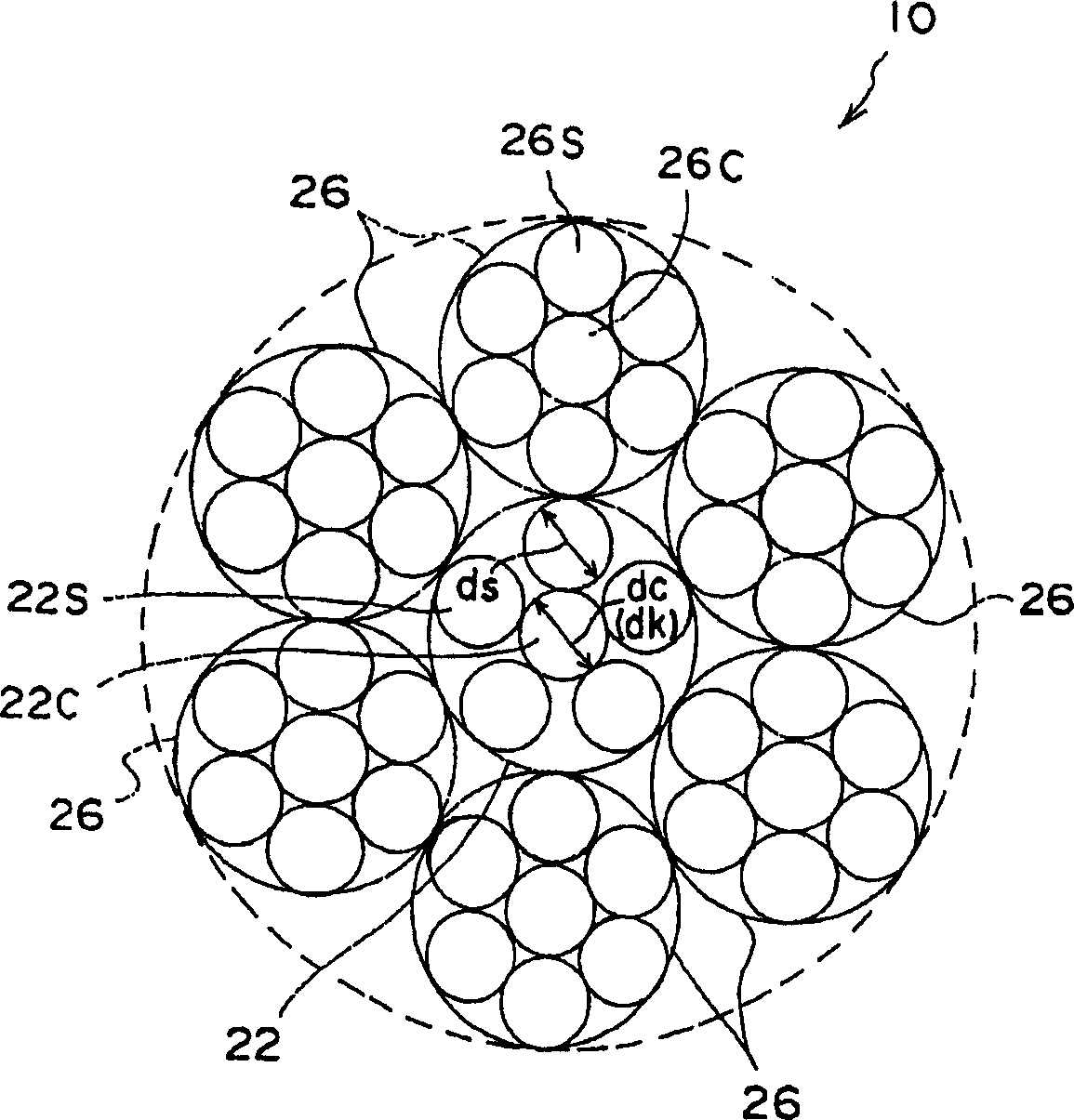

[0028] First, the first embodiment will be described. Such as Figure 1 ~ Figure 3 As shown, the steel cord 10 of the first embodiment is embedded in a rubber track 16 (refer to figure 1 , figure 2 ) in the length direction to serve as steel cords for reinforcing members (main cords). The steel cord 10 is composed of one core strand 22 and six sheath strands 26 twisted around the core strand 22 . The rubber track 16 is initially formed in a jointed belt shape in which both ends of the steel cord 10 protrude. In order to form a jointless loop, a new rubber material 16a is filled with the two ends of the steel cord 10 overlapped and Perform vulcanization molding. In addition, 16b is a core bar embedded in rubber at the same time, and 16c is a plate tooth formed on the outer peripheral side.

[0029] Such as image 3 As shown, the core strand 22 is composed of one core wire 22C and five sheath wires 22S twisted around the core wire 22C. Each of the sheath strands 26 is c...

no. 2 Embodiment approach

[0032] Next, a second embodiment will be described. In the second embodiment, the same reference numerals are attached to the same components as those in the first embodiment, and description thereof will be omitted.

[0033] Such as Figure 4 As shown, the steel cord 30 of the second embodiment is composed of one core strand 32 and six sheath strands 26 twisted around the core strand 32 .

[0034] The core portion 32C of the core strand 32 is composed of three core wires 32C1 to C3 twisted with each other. Thereby, the surface area of the core part 32C can be enlarged, and the impregnation property of the rubber into the core part 32C can be further improved. In addition, in this case, the diameter dk of the core portion 32C (refer to Figure 4 ) is the same as the diameter of the projected locus of the core 32C in the cord length direction.

[0035] As mentioned above, although an Example was given and demonstrated embodiment of this invention, these Examples are only ...

experiment example

[0037] Rubber crawlers using four types of steel cords as steel cords for reinforcement, the steel cord 10 (Example 1), The steel cord 30 (Example 2) described in the above-mentioned second embodiment, the steel cord composed of one core strand and four sheath strands (comparative example), the conventional steel cord (conventional example) . The test condition is 200 hours of walking with rubber tracks. Table 1 shows the core strand structures and filament diameters of Example 1, Example 2, Comparative Example, and Conventional Example (core strand diameter dc of core strand, sheath filament ds of core strand, core portion of core strand) diameter dk) and test results.

[0038] Example 1

Example 2

comparative example

Past example

Core Strand Construction

1+5

3+5

1+4

1+6

Core wire diameter dc(mm)

0.34

0.16

0.34

0.34

Core wire sheath wire diameter ds(mm)

0.34

0.34

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com