Seal for a pressurized container

A technology for pressure vessels and sealing components, applied in structural parts, electrical components, battery pack components, etc., can solve problems such as the dependence of sealing components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

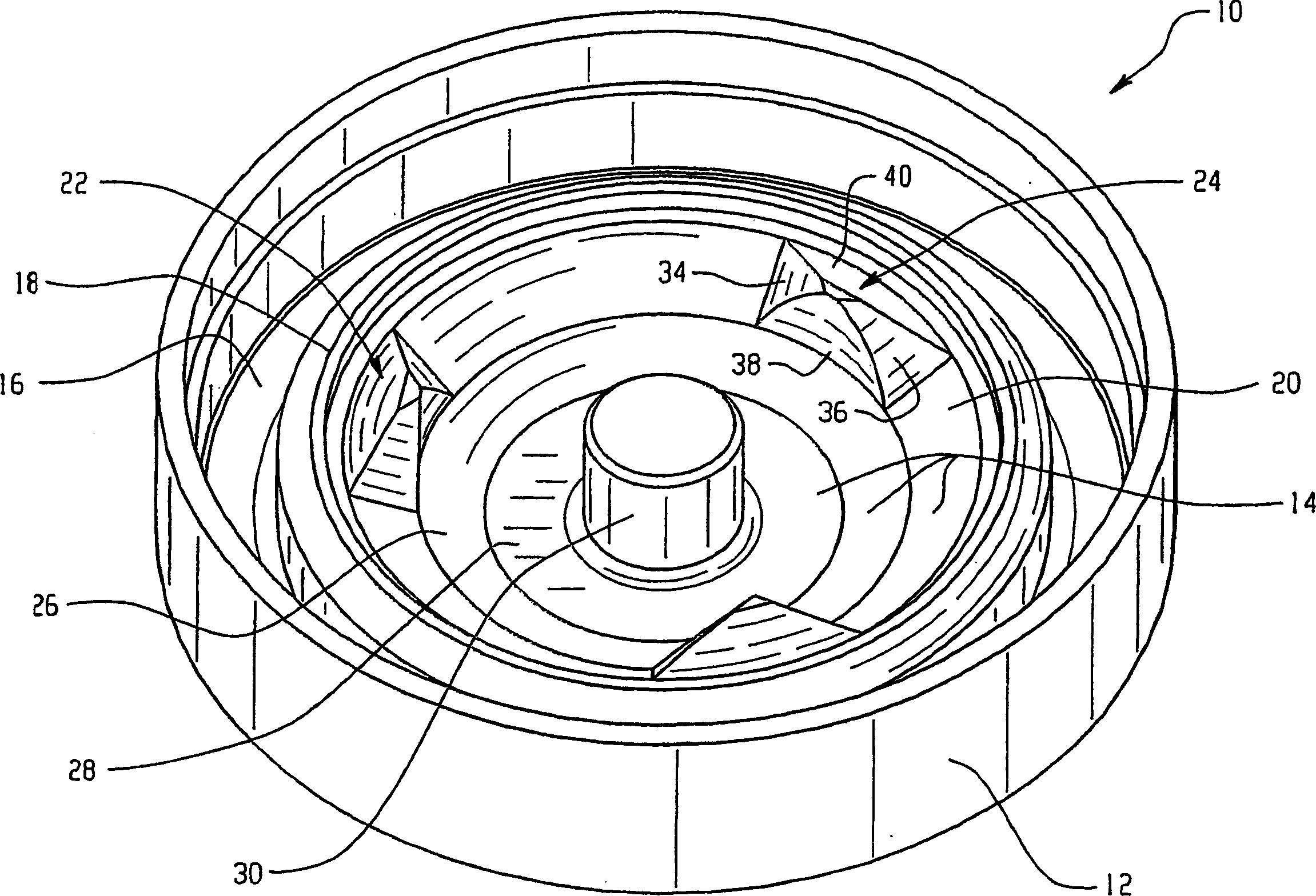

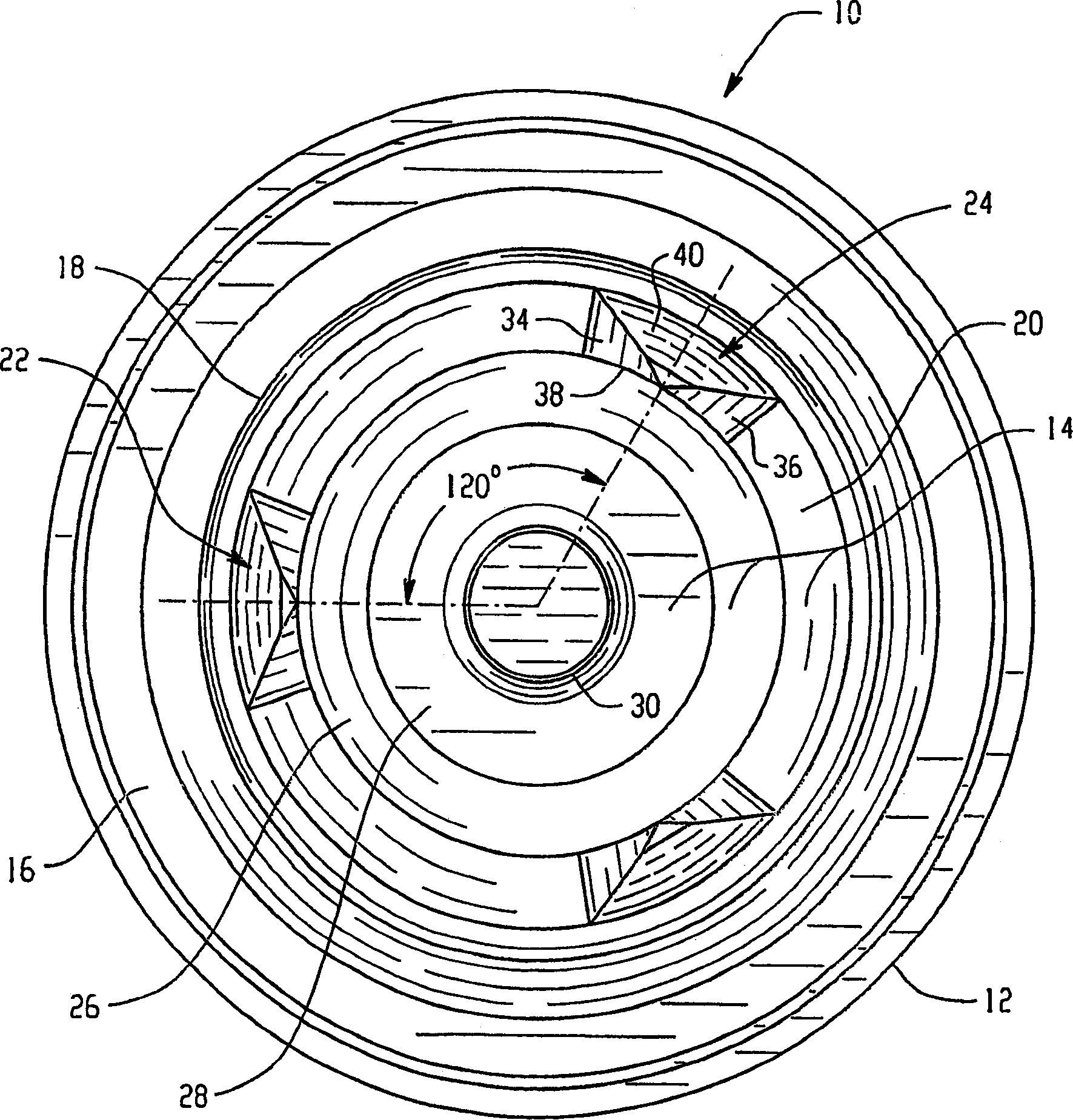

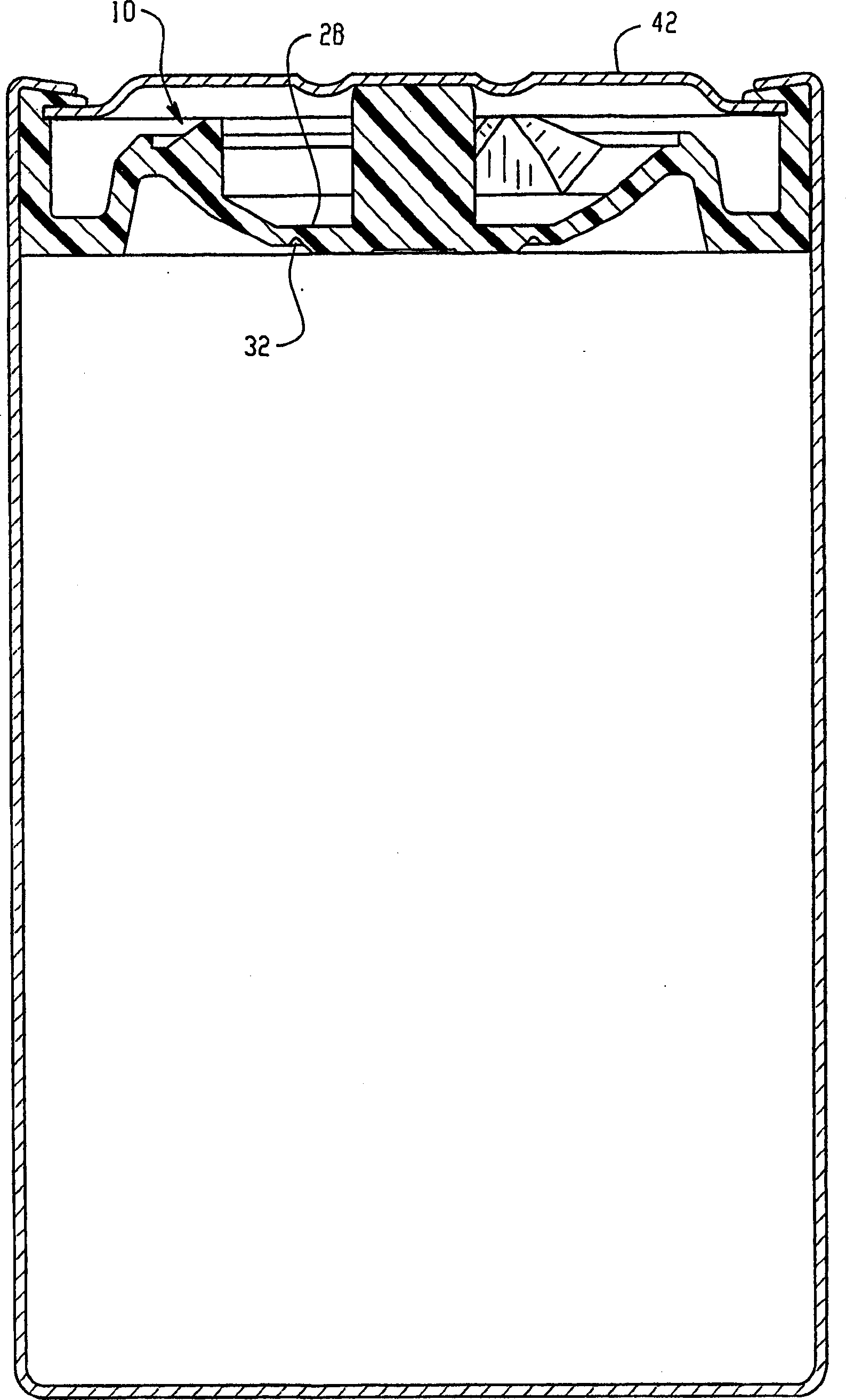

[0016] figure 1 6 to 6 show various views of a sealing member and a pressure vessel including one of said sealing members. Taken together, these drawings and the following description teach those skilled in the art how to practice the claimed invention. In one aspect, the invention is a pressure vessel 50 having a vent assembly 52 including a sealing member 10 and at least one cover 42 . The vent assembly covers the opening 54 in the pressure vessel wall 56 and is secured to the vessel. The vent assembly functions as a pressure-activated safety valve that releases the pressure in the container when the pressure exceeds a predetermined value. The sealing member 10 has a design that can be ruptured along a line of weakness 32 in the membrane region 28 of the sealing member. The torn septum then flexes towards the lid 42 in response to the gas being expelled from within the container. Due to the presence of two or more protrusions 22 and 24 protruding from the upper surface 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com