Image display device and method of manufacturing the same

A technology of image display device and manufacturing method, which is applied to image/graphic display tubes, identification devices, lighting devices, etc., and can solve problems such as incomplete packaging, leakage, and impairment of performance and life of display devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

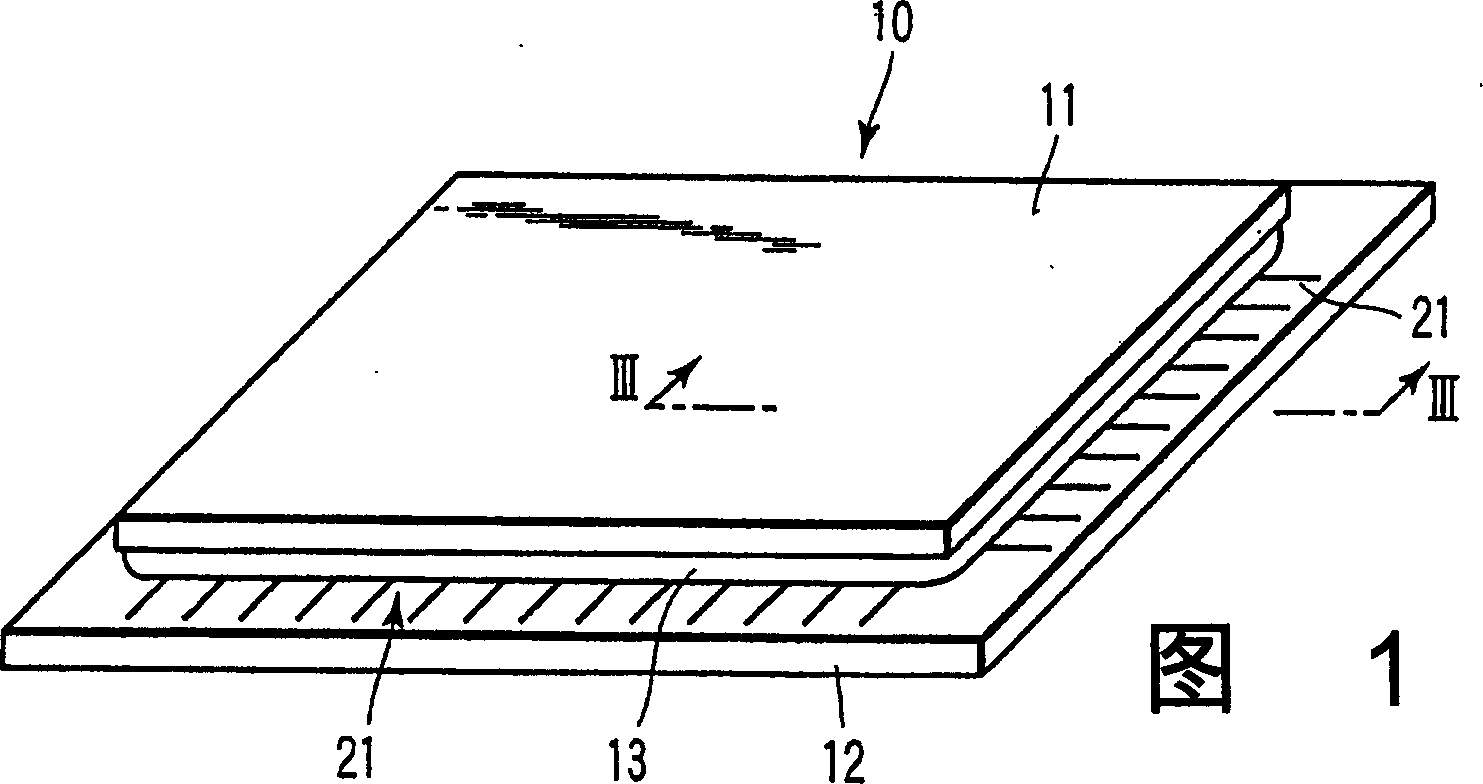

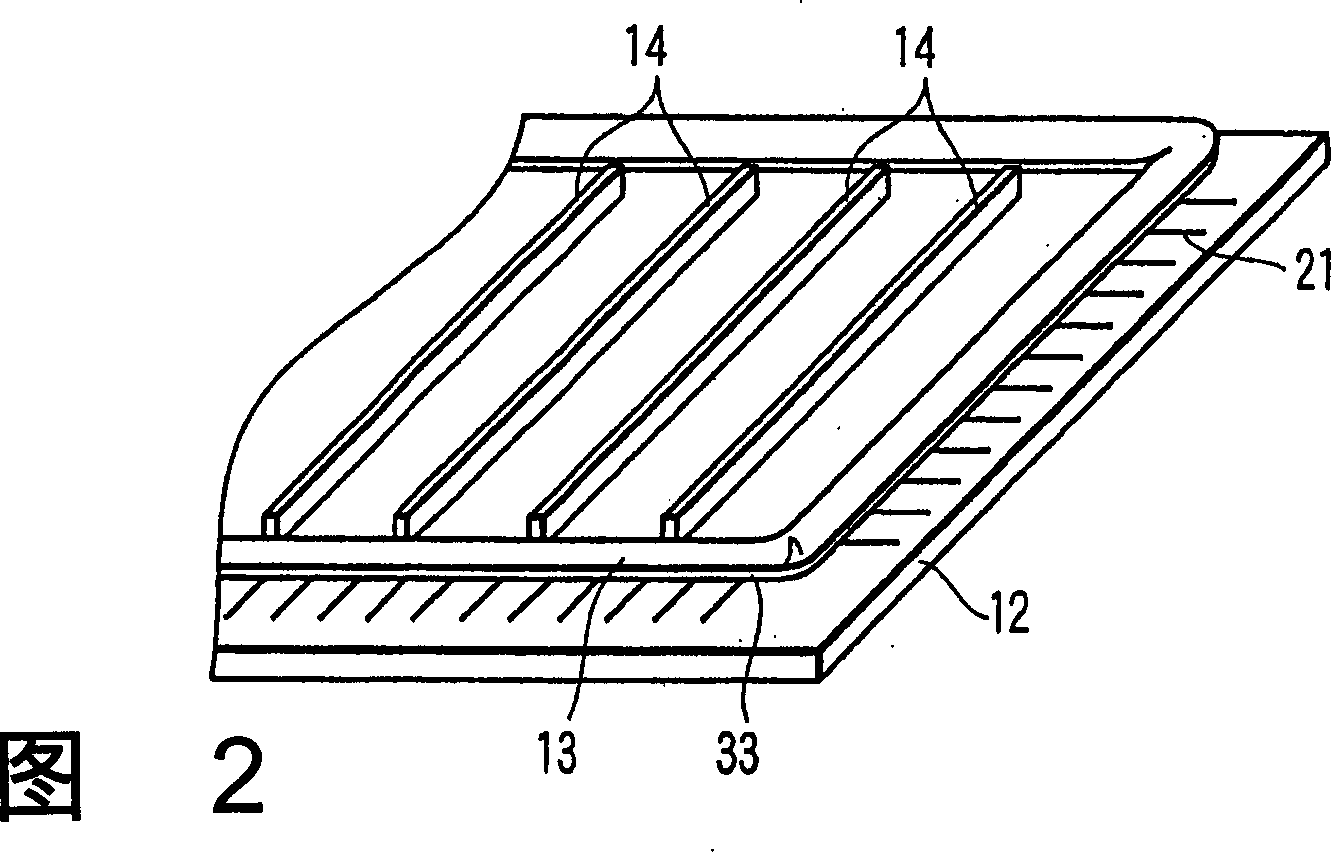

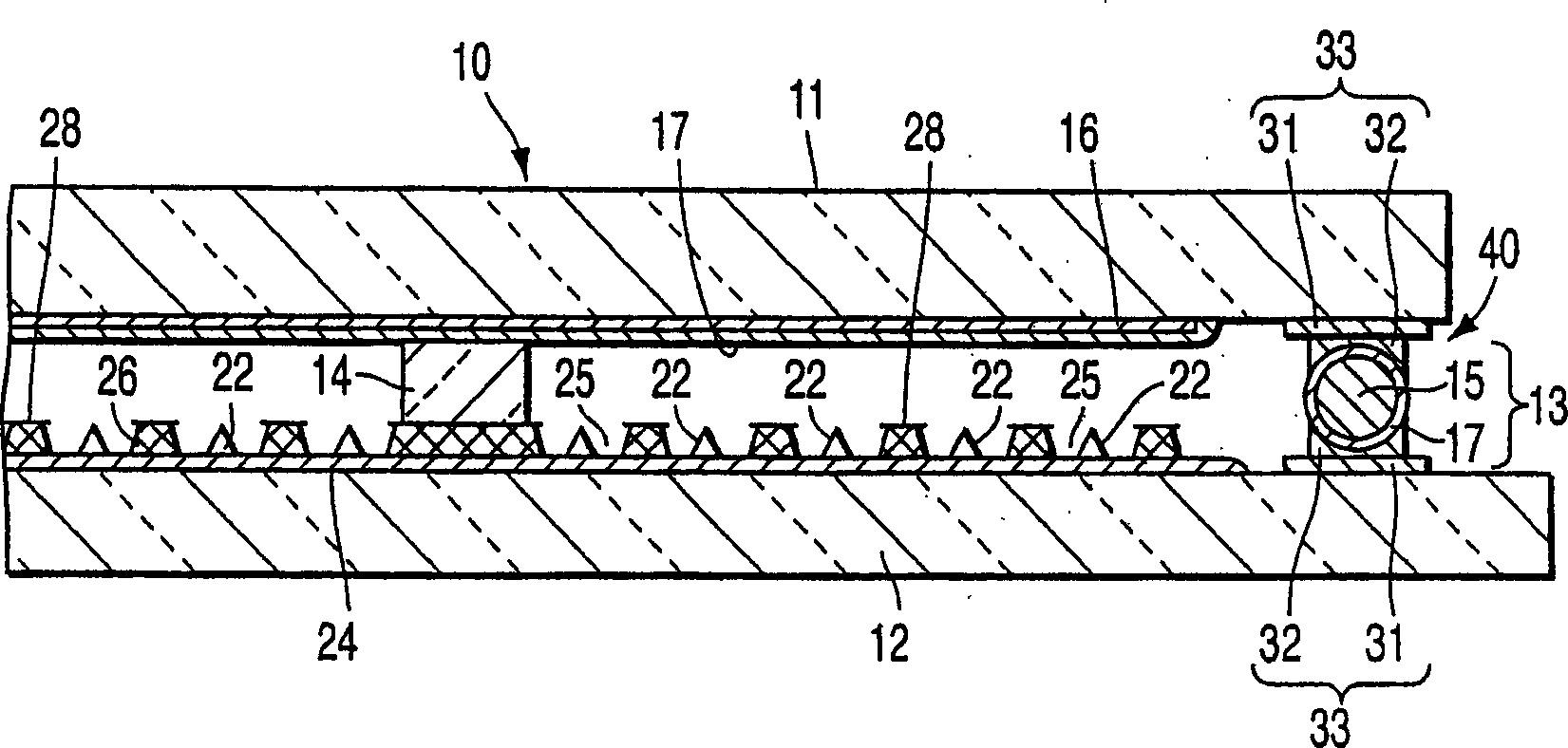

[0026] Embodiments in which an image display device according to the present invention is applied to an FED will now be described in detail with reference to the accompanying drawings.

[0027] As shown in FIGS. 1 to 3, the FED includes a front substrate 11 and a back substrate 12 each composed of a rectangular glass plate as an insulating substrate. These substrates are placed facing each other with a gap of about 1.5 to 3 mm between them. The front substrate 11 and the back substrate 12 have their peripheral edge portions joined together by side walls 13 in the form of rectangular frames, thereby forming a planar rectangular enclosure 10, the inside of which is kept vacuum.

[0028] The respective peripheral edge portions of the front substrate 11 and the back substrate 12 are bonded together by the sealing portion 40 . In particular, the side wall 13 functioning as a frame is located between the sealing surface on the peripheral edge portion on the inner surface of the fro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com