Low head, dynamic variable pitch, submersible hydro generator

A technology for hydroelectric generators and generators, which is applied to the control of generators, ocean energy power generation, engine components, etc. It can solve the problems of doubtful reliability and high cost, and achieve the effect of no pollution and increased power generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

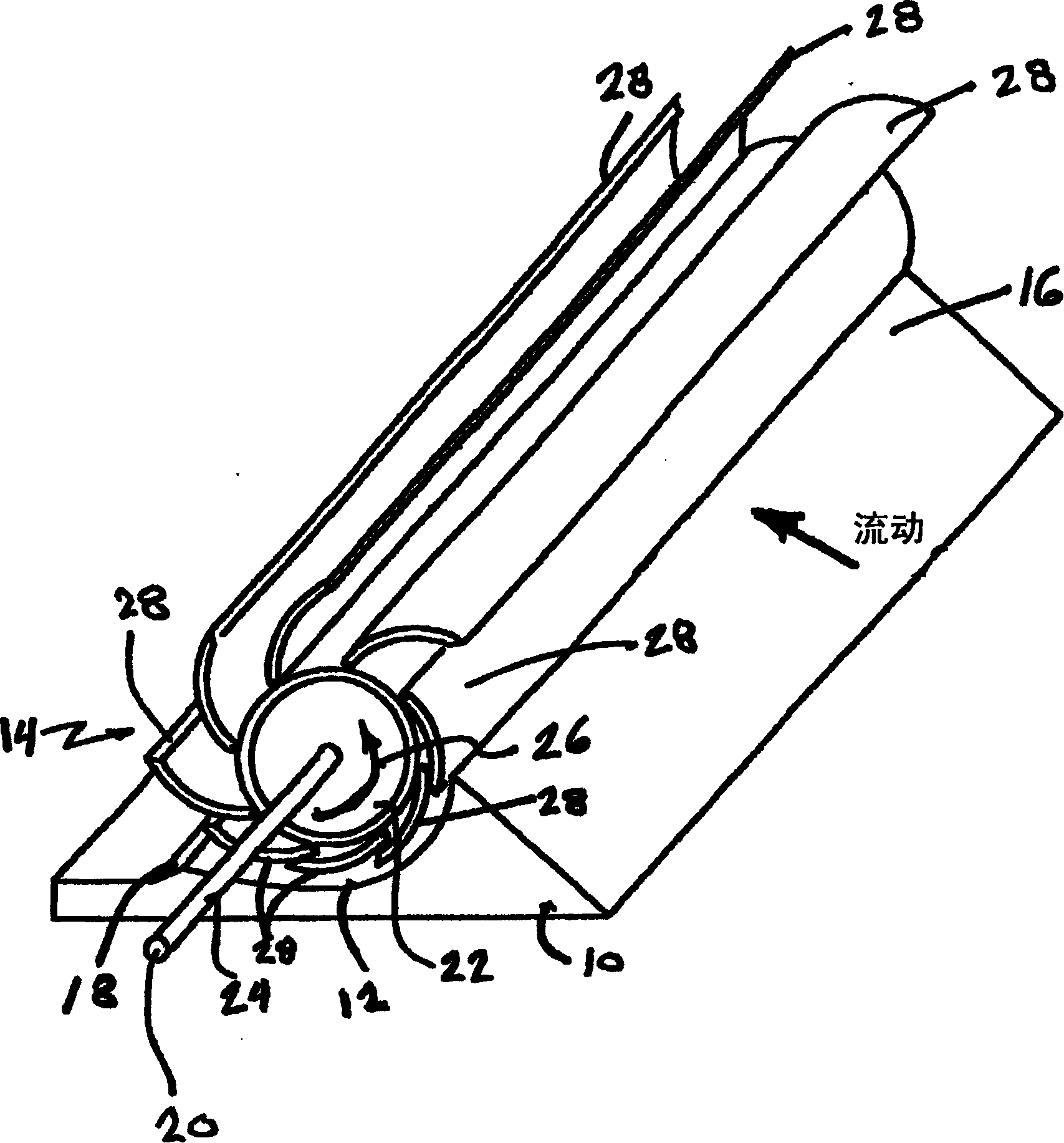

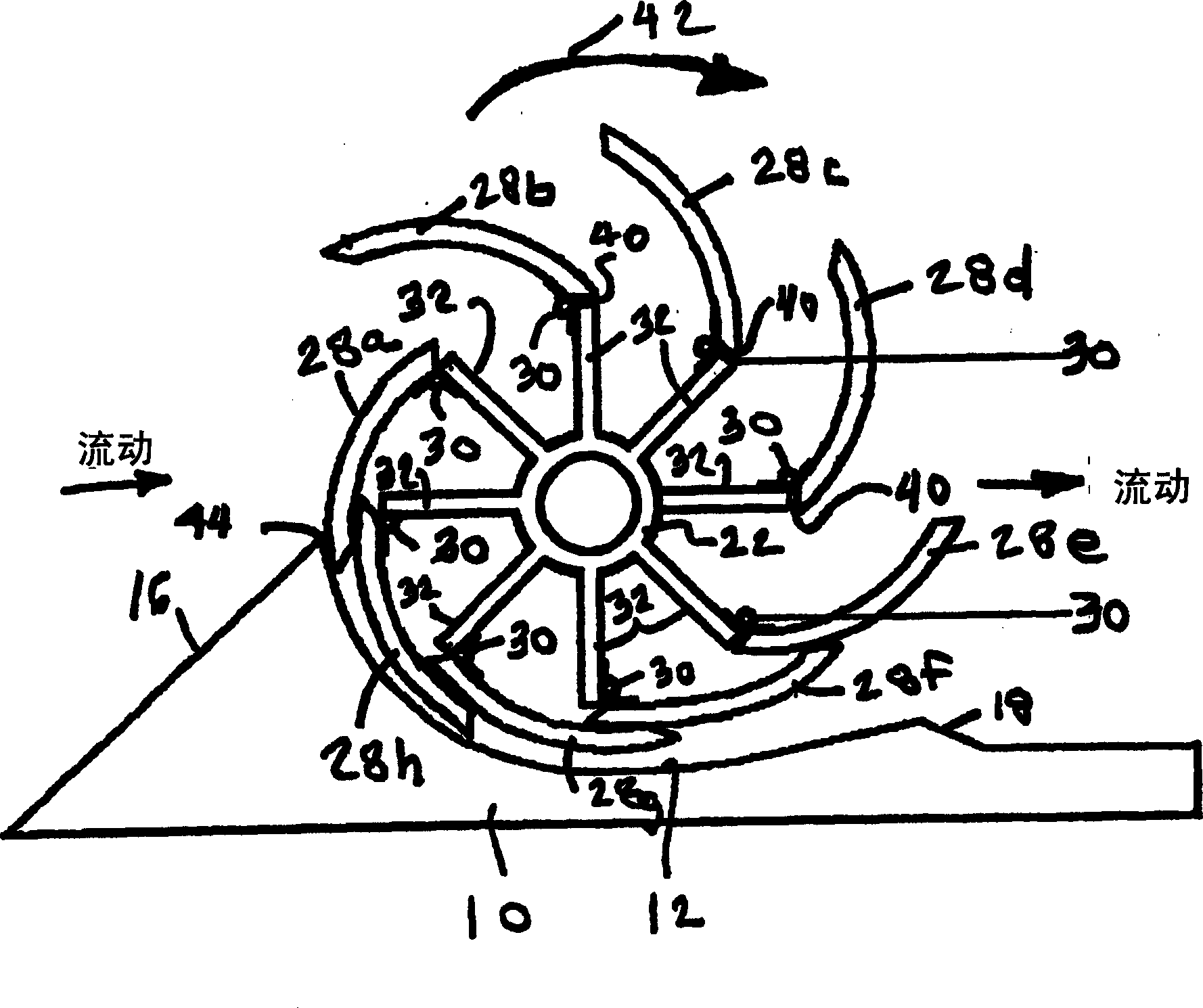

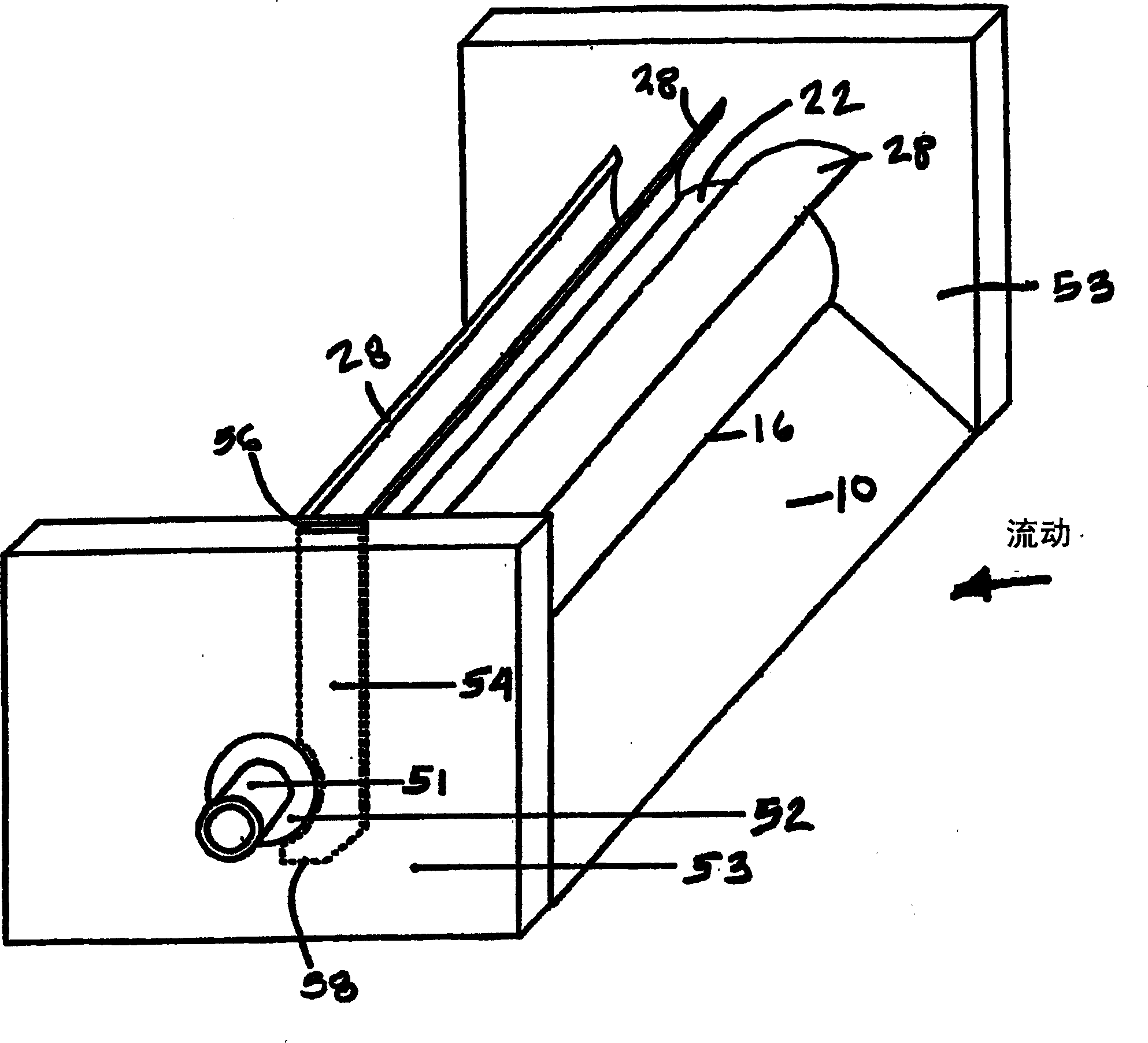

[0036] figure 1 Basic working components are shown. The base 10 is provided so that it is suitable for installation on the bottom surface of a waterway. The longitudinal axis of the base extends to the width or span of the channel and is perpendicular to the direction of flow. In a preferred embodiment, the base is constructed of a heavy inert material such as reinforced concrete. The base can also consist of a hollow high strength plastic so that the hollow can be filled with concrete at the installation site. The base includes a shaped slot 12 for receiving a mandrel and blade assembly 14 . The upstream side 16 of the base is higher than the downstream side 18 and the vane assembly ensures that water flows into the system above the axis of rotation 20 of the mandrel 22 . An axial power shaft 24 connects the spindle. Arrow 26 indicates the direction of rotation.

[0037] Typically, the mandrel 22 is made of a material having high stiffness and high fracture toughness, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com