Limsting PID control method of single input single output system

A single-input, single-output, control method technology, applied to controllers with specific characteristics, adaptive control, electric controllers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

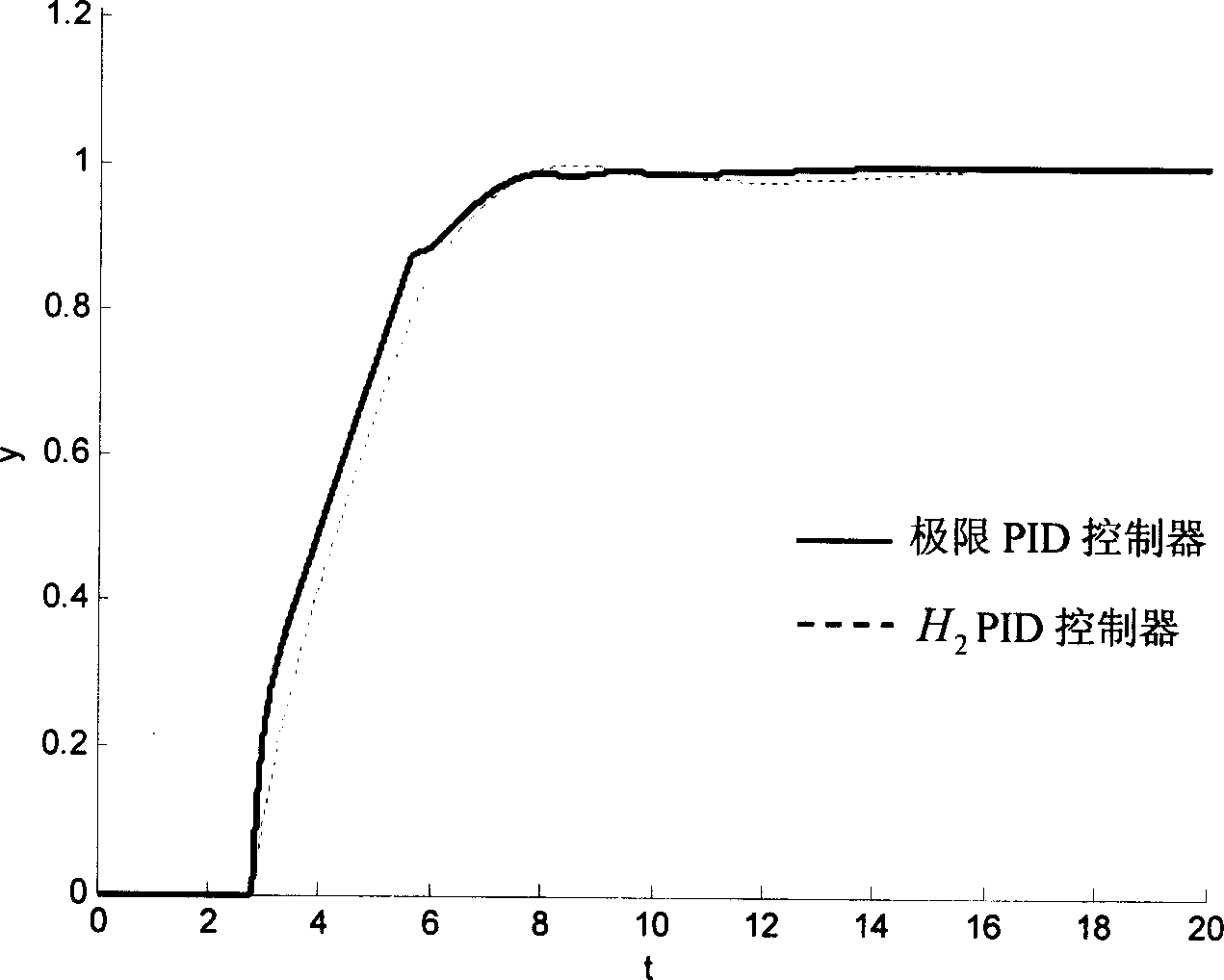

Image

Examples

Embodiment

[0051] The control method proposed by the present invention is used in the automatic control system of the papermaking production process, and its purpose is to produce paper with constant weight. The so-called quantitative here is the weight of paper per square meter. The control object of the system is a typical fourdrinier paper machine. In the papermaking process, the medium-consistency pulp sent from the beating section is mixed with the recovered white water under the wire to become low-consistency pulp suitable for online feeding, which is transported to the headbox, which can be the input of the paper machine. Then it is sprayed from the outlet of the slice plate of the headbox to the net, and the pulp is filtered on the net to remove most of the water to form a wet paper sheet and then enter the press section. Most of the remaining moisture then enters the drying section and is heated in a series of drying cylinders filled with high-temperature steam, so that the moi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com