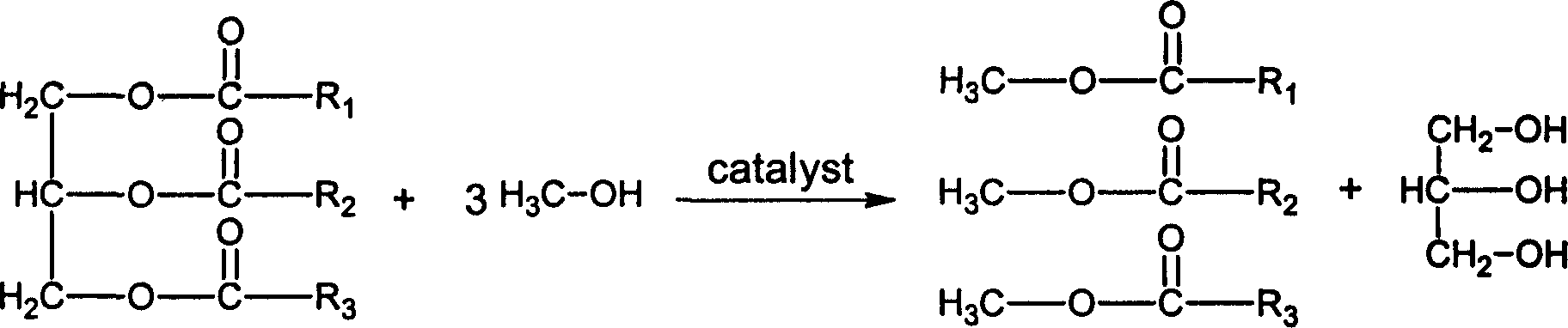

Organic solvent slow-releasing system and its preparation and application for catalyzing reaction of enzyme thereof

A technology of organic solvent and liquid organic matter, which is applied to the slow release system of organic solvent and its preparation and application in enzyme catalyzed reaction, can solve the problems of excess, catalyst deactivation and the like, achieves low cost and is beneficial to large-scale industrial production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Preparation of Ethanol Silica Sustained Release System

[0031] Soak 10 grams of 3nm microporous silica gel (granular) that has been dehydrated with 40 ml of absolute ethanol for 7 hours to reach saturation, filter it out, and dry the surface to obtain a methanol-saturated silica gel slow-release system.

Embodiment 2

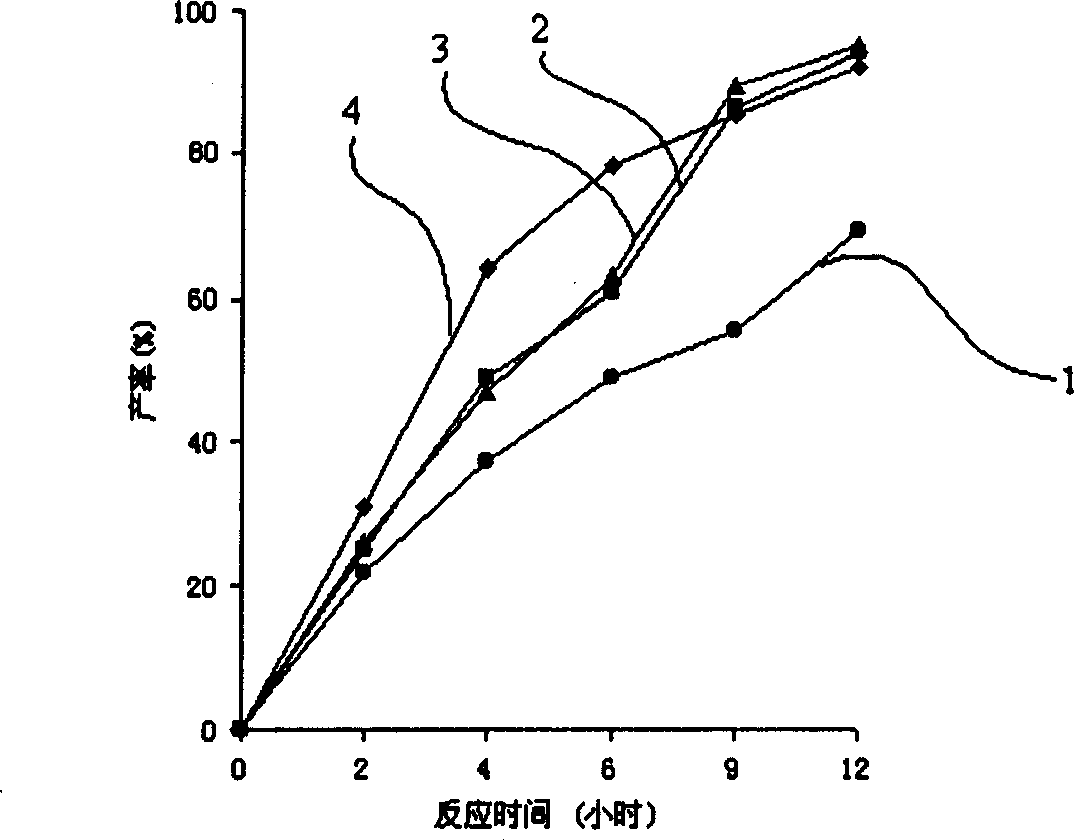

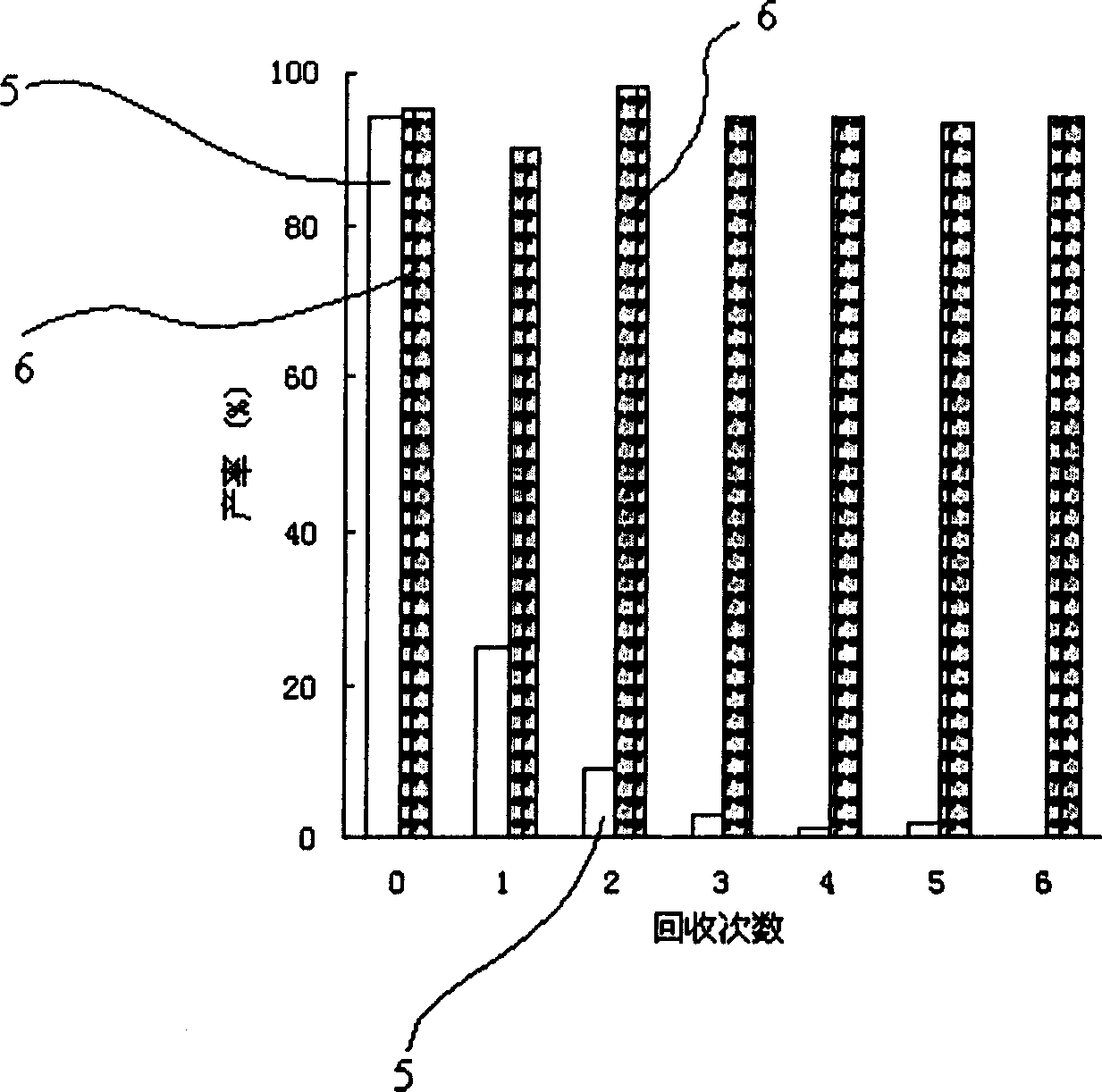

[0033] Yield comparison of methanol silica gel slow-release system and traditional three-step methanol addition method for biodiesel production

[0034] Soak 10 grams of 4nm microporous silica gel (granular) that has been dehydrated in 40 ml of anhydrous methanol for 10 hours to reach saturation, filter it out, and dry the surface to obtain a methanol-saturated silica gel slow-release system for use.

[0035] Dissolve 1.5 grams of soybean oil in 7.5 milliliters of n-heptane, add 0.5 grams of immobilized lipase, and add methanol respectively: 1) Traditional three-step methanol addition method, every 2 hours, add 70 microliters of anhydrous methanol ; 2) 0.3 g, 1.0 g, and 2.0 g of methanol-saturated silica gel slow-release systems were added at one time, respectively.

[0036] 3 The reaction was shaken at 180rpm at 30°C for 12 hours. The obtained system was vacuum rotary evaporated at 45°C to remove the solvent and methanol, and the residue was extracted from the unreacted raw m...

Embodiment 3

[0040] Production of Biodiesel with Methyl Acetate Silica Gel Sustained Release System

[0041] Soak 10 grams of 2nm silica gel (granular) dewatered in 40 milliliters of anhydrous methyl acetate for 4 hours to reach saturation, filter it out, and dry the surface to obtain a silica gel slow-release system saturated with methyl acetate.

[0042] Dissolve 1.5 g of sesame oil in 7.5 ml of cyclohexane, add 0.5 g of immobilized lipase, and add 2.0 g of methyl acetate-saturated silica gel slow-release system at one time. 4 The reaction was shaken at 180rpm at 30°C for 24 hours, and the obtained system was vacuum rotary evaporated at 40-50°C to remove the solvent and methyl acetate, and the residue was extracted from the unreacted raw materials with methanol, and vacuum rotary evaporation was performed again, then Crude biodiesel is available. Sampling and testing product yield can reach 90%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com