Automatic control system for torque of concentration machine

An automatic control system, torque control technology, applied in the direction of control/adjustment system, torque/mechanical power control, non-electric variable control, etc., can solve the problems of low power factor, lack of thickener, difficult operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

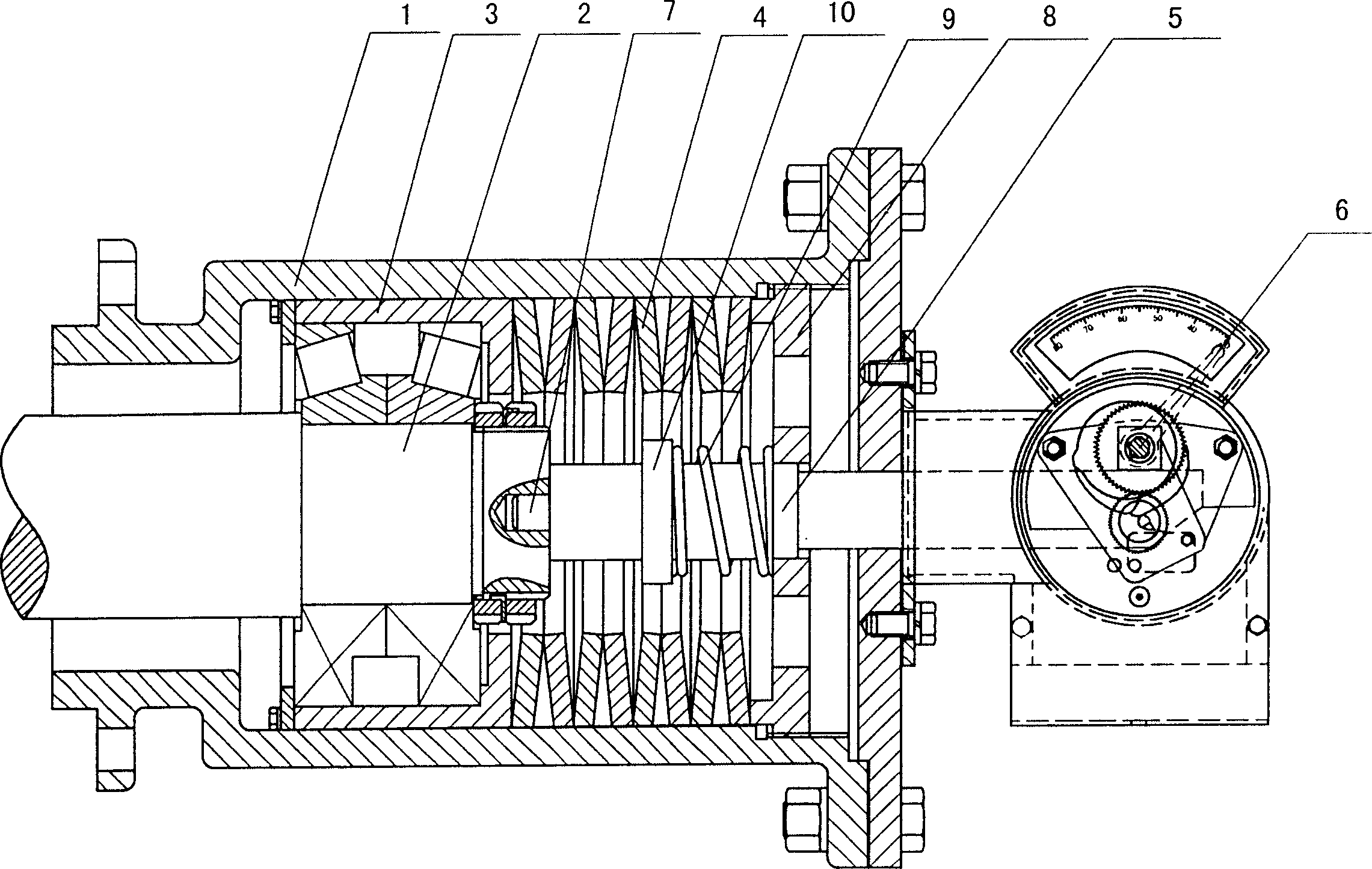

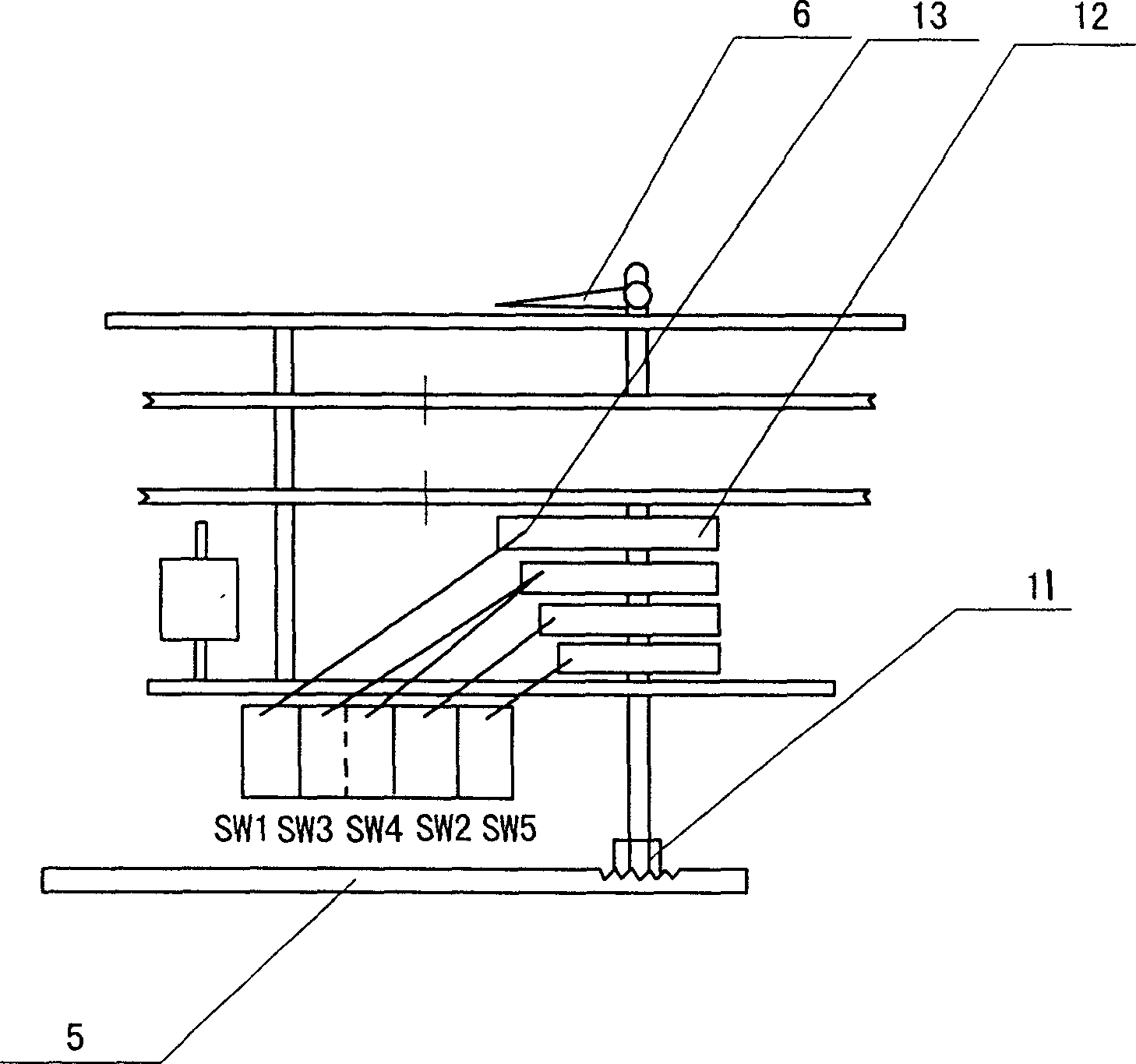

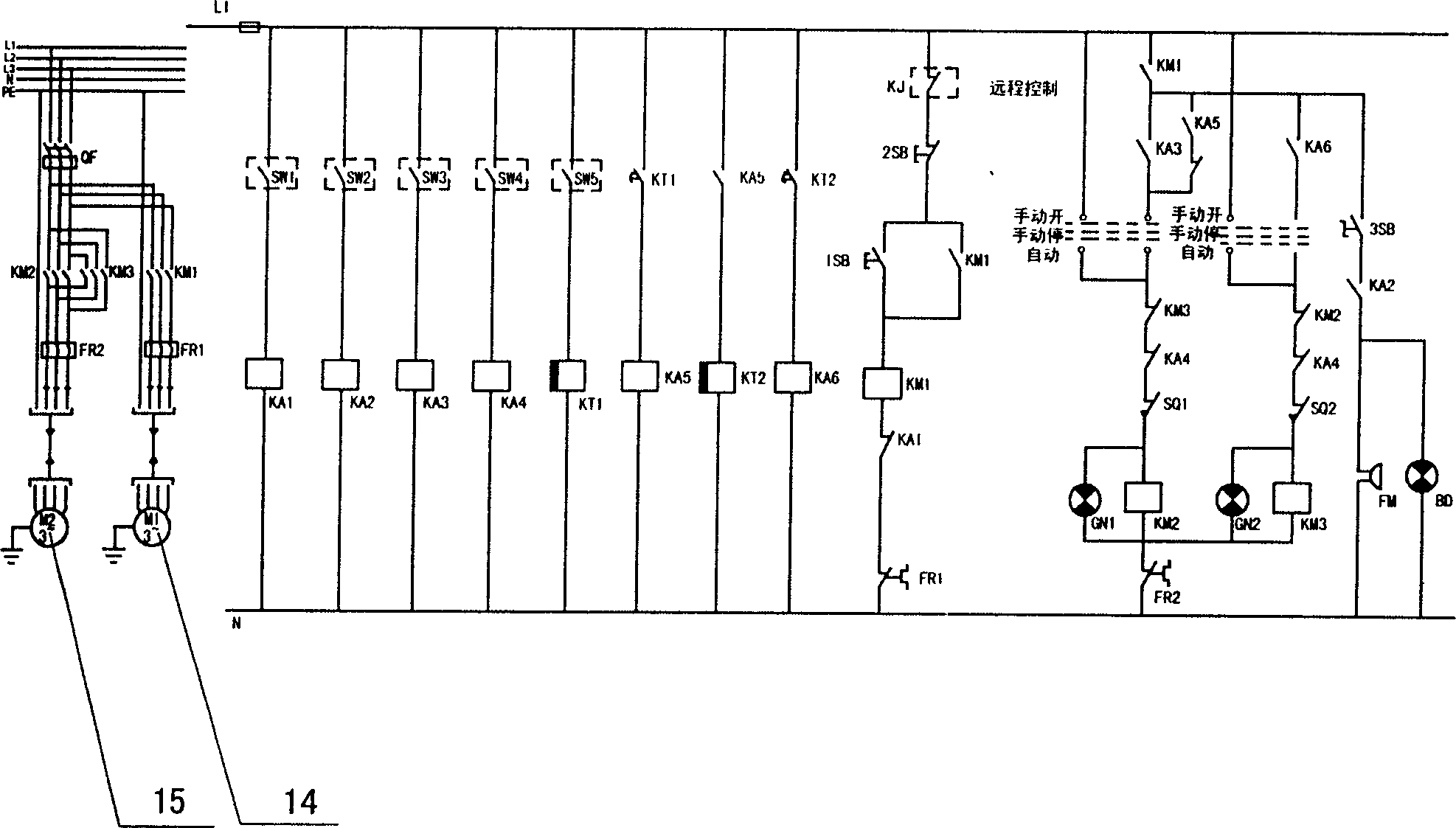

[0013] With reference to the attached drawings, the automatic torque control system of thickener is mainly composed of torque measuring device and torque control part. The torque measuring device is mainly composed of housing 1, spline bushing 2, sliding sleeve 3, butterfly spring 4, sensing shaft 5 and torque pointer 6. The spline bushing 2 and sensing shaft 5 are located on the same axis Inside the housing 1, the front and rear central holes of the housing 1 are respectively passed through. The end of the sensing shaft 5 that is adjacent to the spline sleeve 2 is a mating end 7, and the mating end 7 extends into the center hole of the spline sleeve 2. The spline bushing 2 and the reducer shaft are connected by a spline, and the two can be axially displaced relatively. The sliding sleeve 3 and the butterfly spring 4 are located in the housing 1, and a bearing is provided in the sliding sleeve 3 for supporting the spline shaft sleeve 2. The limit plate 8 is fixed on the inner side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com