Welding seam tracking sight sensor based on laser structure light

A technology of laser structure and visual sensing, applied in the field of robotics, can solve the problems of lack of general, flexible and independent welding sensors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

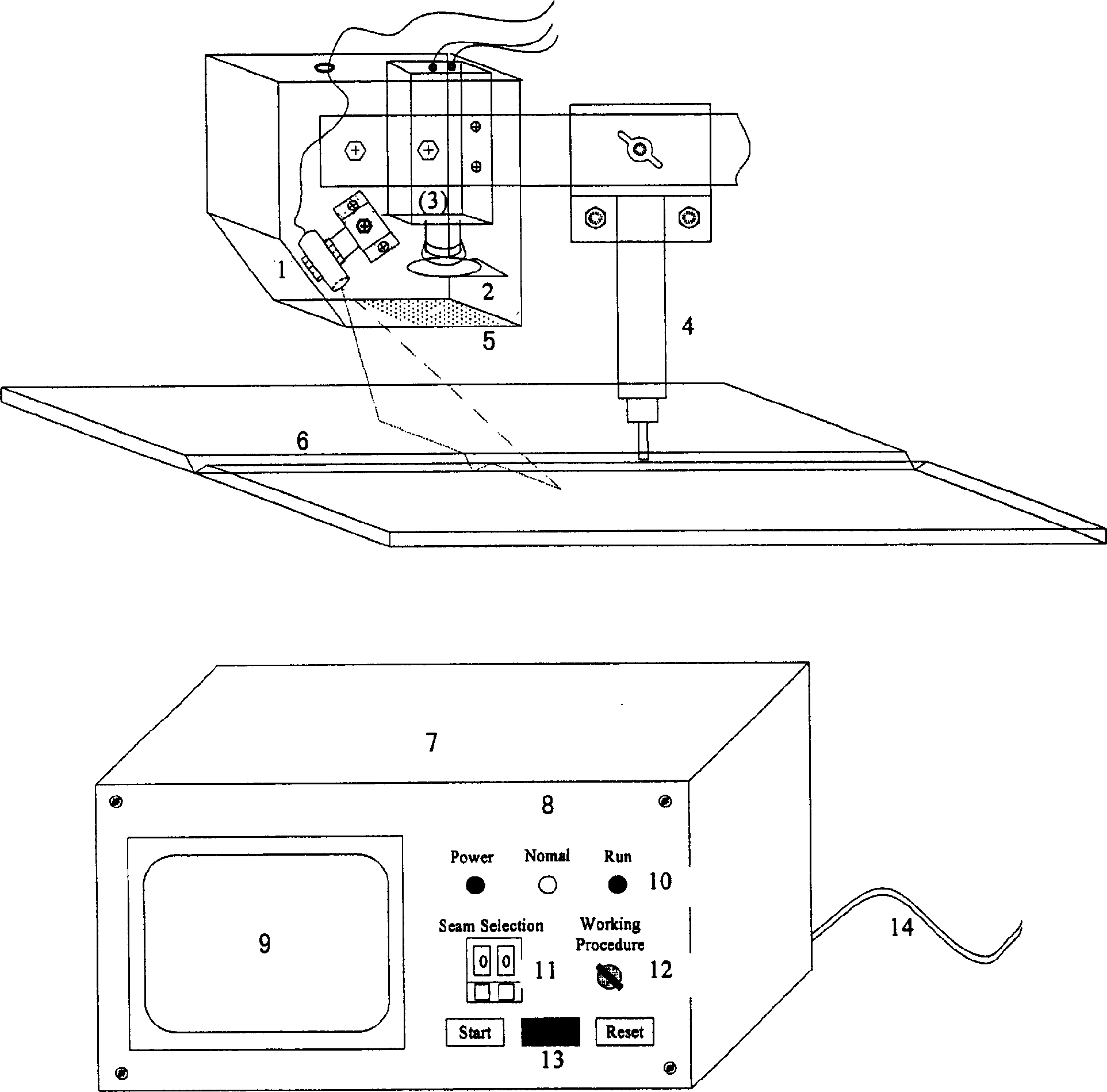

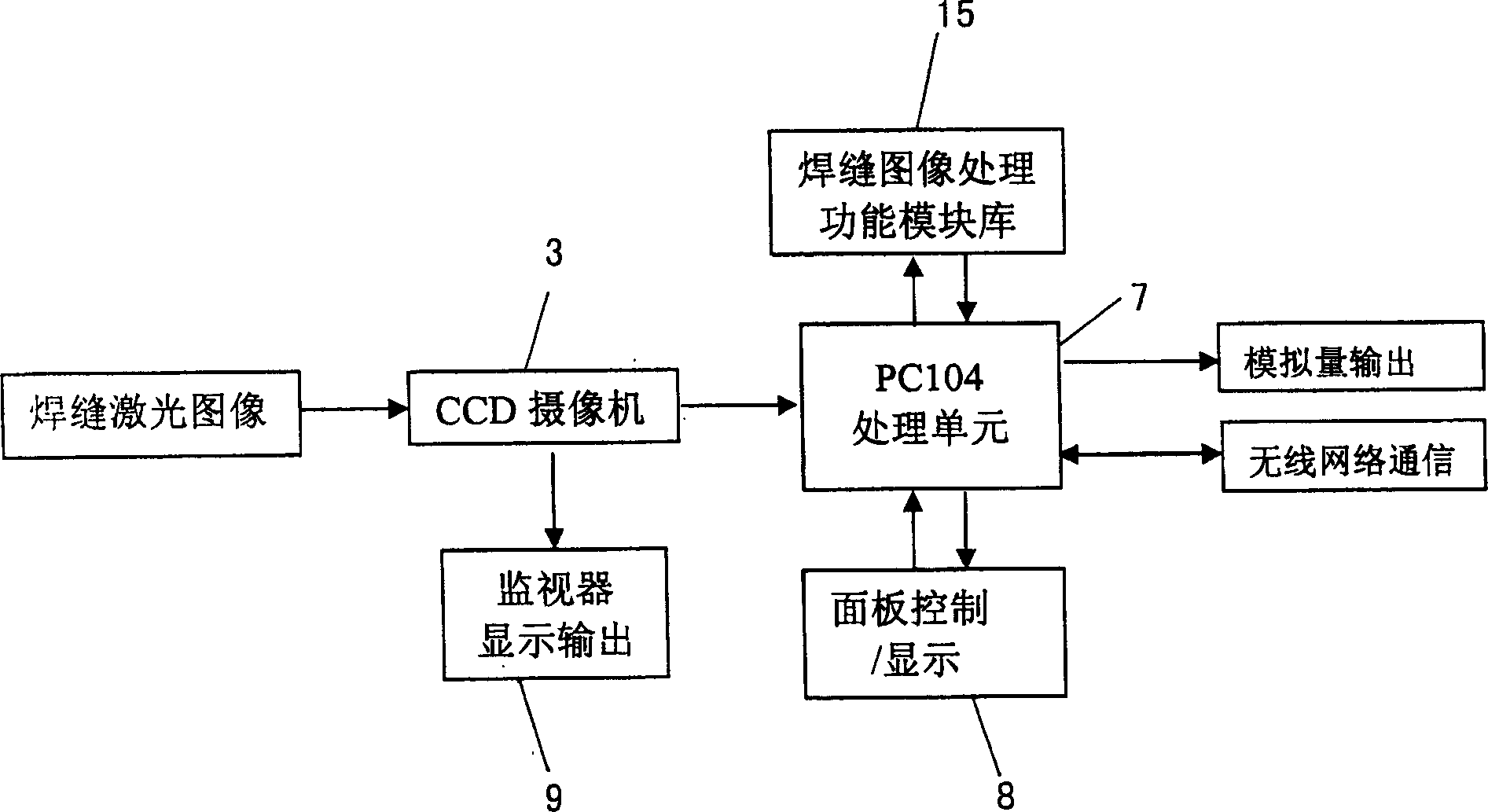

[0020] see figure 1 . exist figure 1 Among them, the laser beam emitted by the semiconductor flat-line laser (LD650-5-3) 1 produces a structured light plane, which irradiates the surface of the welding workpiece to form the characteristic laser stripes of the weld 6. The laser line width is 0.5mm, the spread angle is 20°, and the power is 5mw. WATEC505 black-and-white industrial camera 3 has a filter on it, which can transmit light waves with a wavelength of 670nm. A splash guard 5 is installed below the video camera 3, which can block welding spatter and protect the video camera. The laser 1 , optical filter 2 , camera 3 and splash guard 5 are packaged in the sensor housing, and the sensor is rigidly connected with the welding torch 4 . The position and angle of the inline laser 1 can be adjusted. Adjust the angle between the laser 1 and the camera 3 so that the center line of the optical axis of the camera 3 forms an angle of 30° to 60° with the laser structured light su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com