Fluid bearing device

A technology of fluid bearings and bearing components, applied in the directions of bearings, shafts and bearings, mechanical equipment, etc., can solve the problems of bearing rigidity decline, bearing distortion, adverse effects of NRRO, etc., and achieve the effect of stable transportation and handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

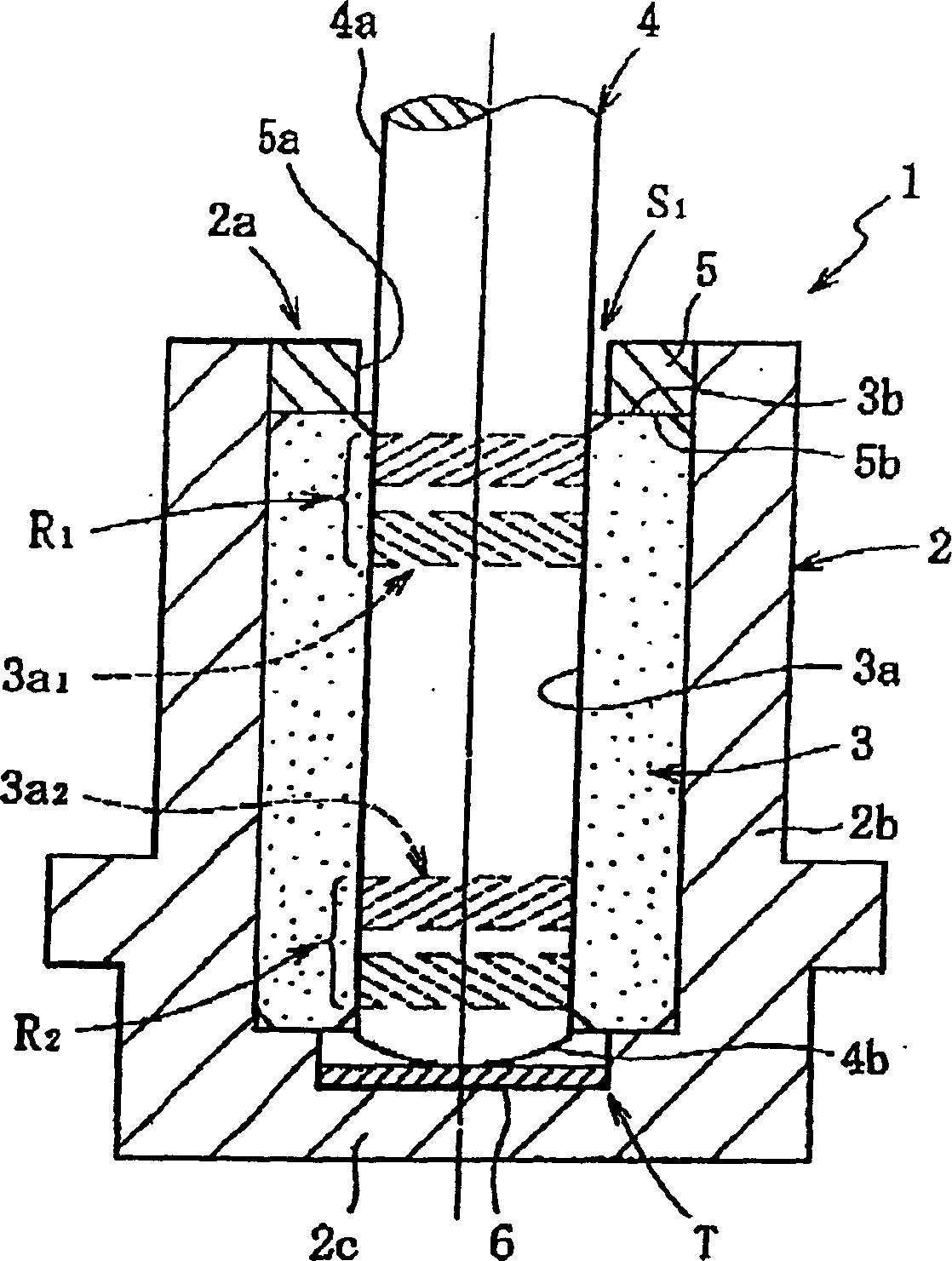

[0159] In the fluid bearing device 1 of the form shown in FIG. 1, lubricating oil is injected under the above-mentioned form (vacuum immersion oil), and by changing the vacuum degree in the vacuum chamber at that time, the inner space of the sleeve 2 after being opened under atmospheric pressure is manufactured. Five types of test bearing devices (Examples 1 to 2, Comparative Examples 1 to 3) with different amounts of residual air were produced. It is difficult to measure the amount of residual air in the inner space of the sleeve after vacuum oil immersion, but for example, if the vacuum degree in the vacuum tank is reduced to 380 Torr (1 / 2 of the atmospheric pressure), it can be estimated that it is open in the atmospheric pressure. 50vol% of the air in the inner space remains in the rear sleeve, so the residual air volume is calculated in this way.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com