Surface acoustic wave device and electronic apparatus

A surface acoustic wave and electronic equipment technology, applied in the direction of electrical components, impedance networks, etc., can solve the problems of reduced yield and unsuitable for high frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

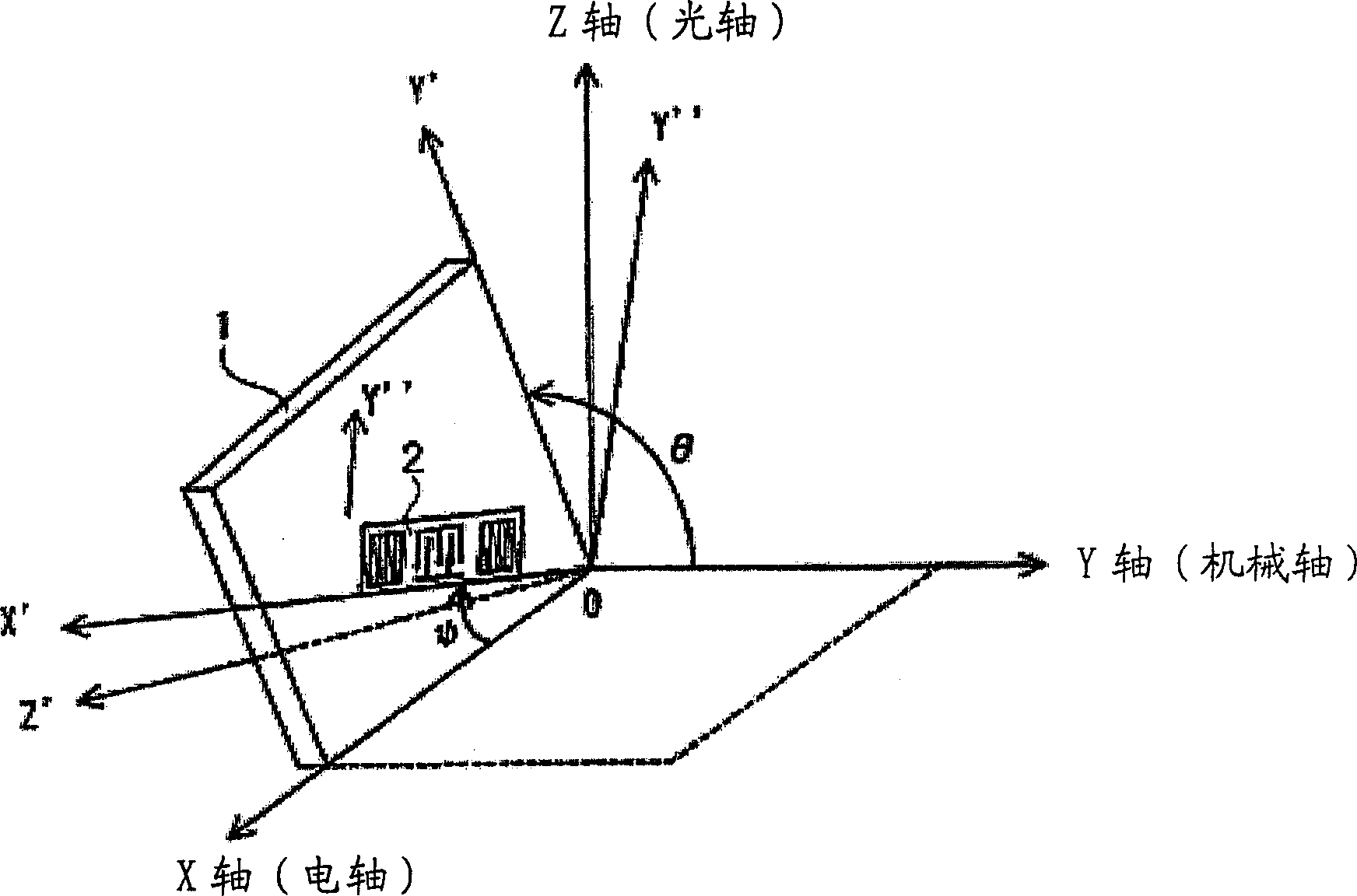

[0046] Next, an embodiment of the present invention will be described by taking a SAW resonator as an example of a surface acoustic wave device.

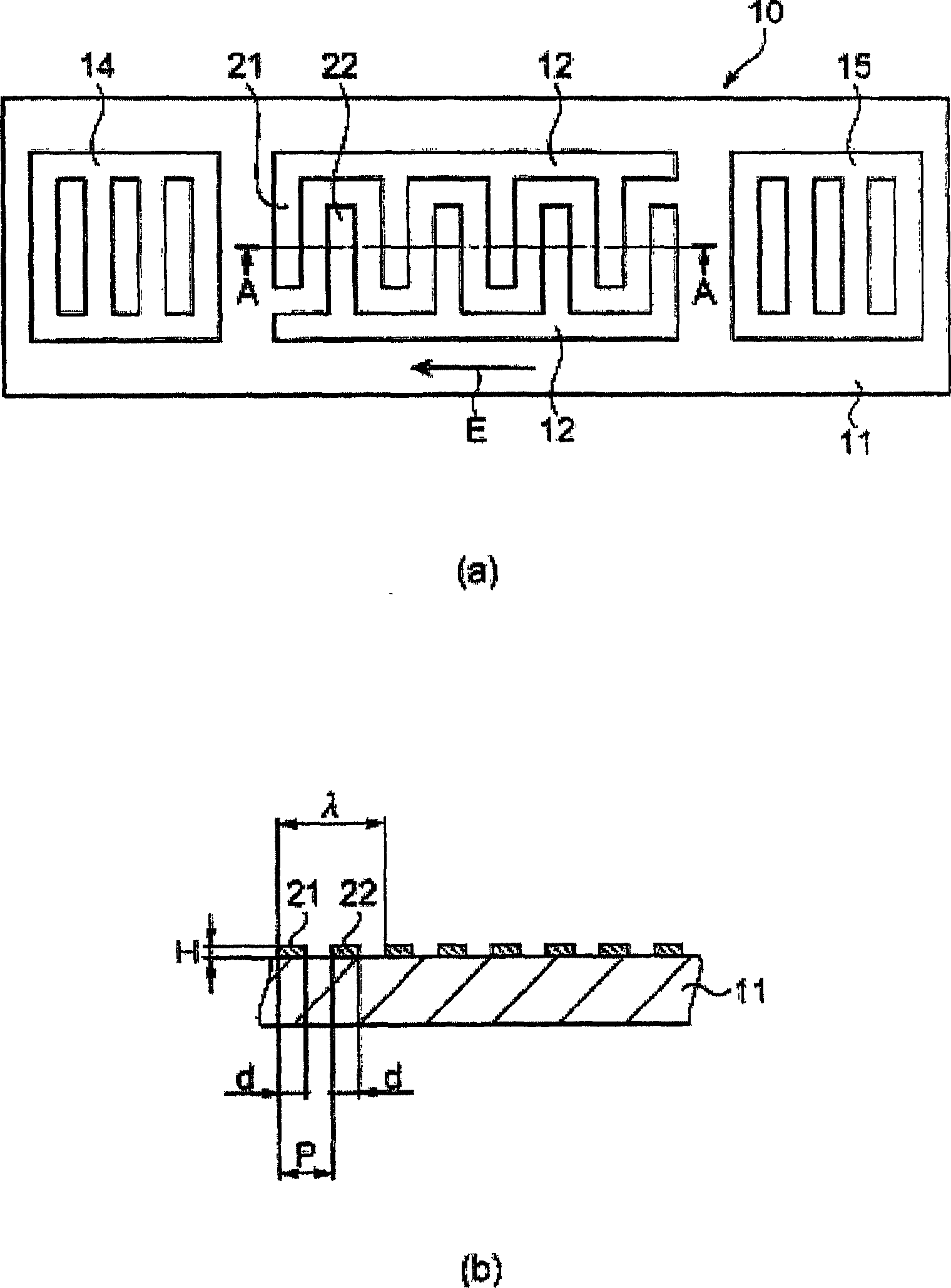

[0047] image 3 is a schematic diagram of a SAW resonator as a surface acoustic wave device with a single-type IDT electrode. image 3 (a) is a schematic plan view of a SAW resonator, image 3 (b) is a schematic cross-sectional view along the section line A-A of (a) of the figure.

[0048] The SAW resonator 10 is composed of: an IDT electrode 12 having electrode fingers 21 , 22 on the surface of a quartz substrate 11 ; and reflectors 14 , 15 provided at both ends of the IDT electrode 12 . The IDT electrode 12 is arranged such that the respective electrode fingers 21 , 22 engage with each other. The electrode fingers 21 and 22 are formed according to the thickness H and the electrode width d, and the interval (pitch) P between the electrode fingers 21 and the electrode fingers 22 is continuously formed at equal intervals. In addi...

no. 2 Embodiment approach

[0069] Alternatively, the image 3 The cut-out angle of the quartz substrate 11 of the shown SAW resonator and the propagation direction of the surface acoustic wave are set within the range of Euler angles (0°, 0°≤θ≤180°, 9°≤|ψ|≤46°) .

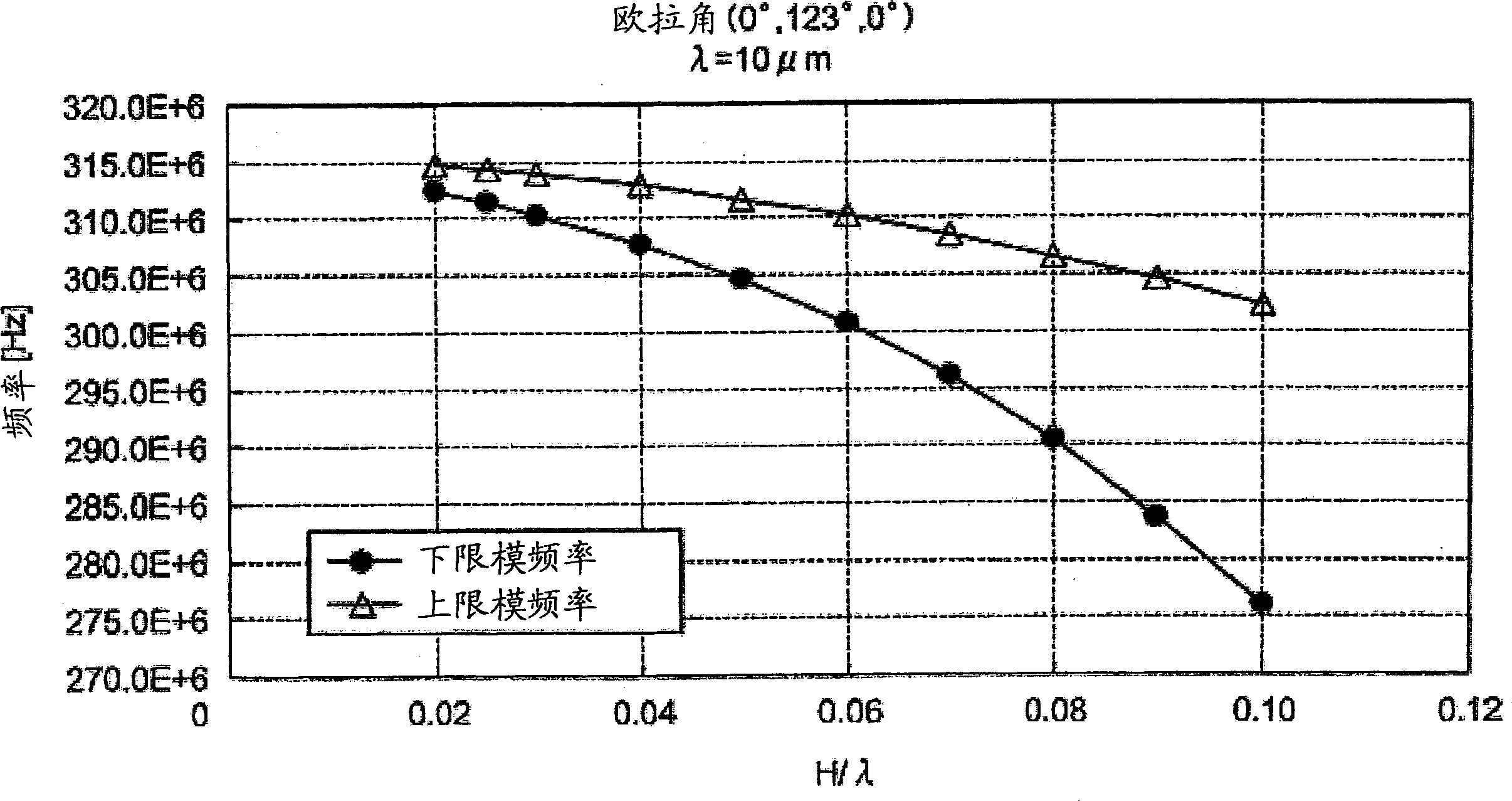

[0070] At this time, if Figure 4 As shown, when the temperature range is -40°C to 90°C, the amount of frequency variation is a maximum of about 127ppm. The secondary temperature coefficient of the ST-cut quartz substrate is generally -3.4×10 -8 (1 / °C 2 ), when the temperature range is -40°C to 90°C, the frequency variation is about 144ppm.

[0071] In this way, by setting the cutting angle of the quartz substrate 11 of the surface acoustic wave device and the propagation direction of the surface acoustic wave within the range of Euler angles (0°, 0°≤θ≤180°, 9°≤|ψ|≤46°) Within, the amount of frequency variation can be reduced compared to the case of using an ST-cut quartz substrate.

no. 3 Embodiment approach

[0073] Also, you can add image 3 The cut-out angle of the quartz substrate 11 of the shown SAW resonator and the propagation direction of the surface acoustic wave are set within the range of Euler angles (0°, 95°≤θ≤155°, 33°≤|ψ|≤46°) .

[0074] At this time, if Figure 4 As shown, in the case where the temperature range is -40°C to 90°C, the amount of frequency variation becomes a maximum of about 59ppm. In addition, in the in-plane rotating ST-cut quartz substrate, according to the document "Temperature Stability of Surface Acoustic Wave Resonators onIn-Plane Rotated 33°Y-Cut Quartz" JJAP, Vol.42(2003)pp.3136-3138, in Europe In the case of pulling angles (0°, 123°, 43.4°), the second temperature coefficient of the lower limit mode of the stop band is -1.4×10 -8 (1 / °C 2 ), when the temperature range is -40°C to 90°C, the frequency variation is about 59ppm.

[0075] In this way, by setting the cutting angle of the quartz substrate 11 of the SAW resonator and the propagat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com