Convection portion structure of convection electronic microwave oven

A microwave oven and electronic technology, which is applied in household stoves/stoves, electric heating fuel, household heating, etc., can solve the problems of rising manufacturing costs and increasing assembly processes, and achieve the effects of reducing manufacturing time and manufacturing costs and improving structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0041] In the following description, the parts that have the same structure as those of the conventional convection microwave oven use the same numbers, and the detailed description is omitted here.

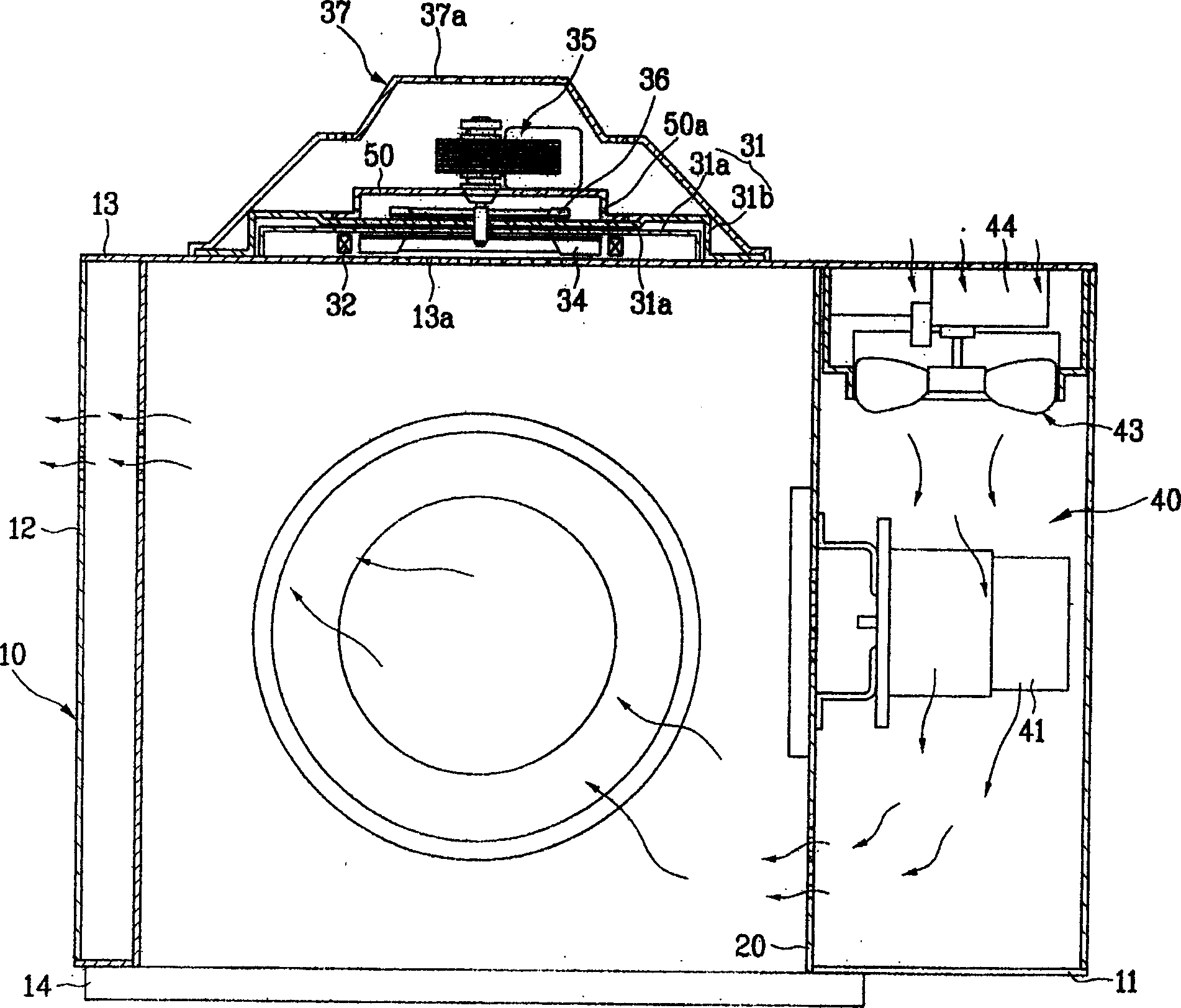

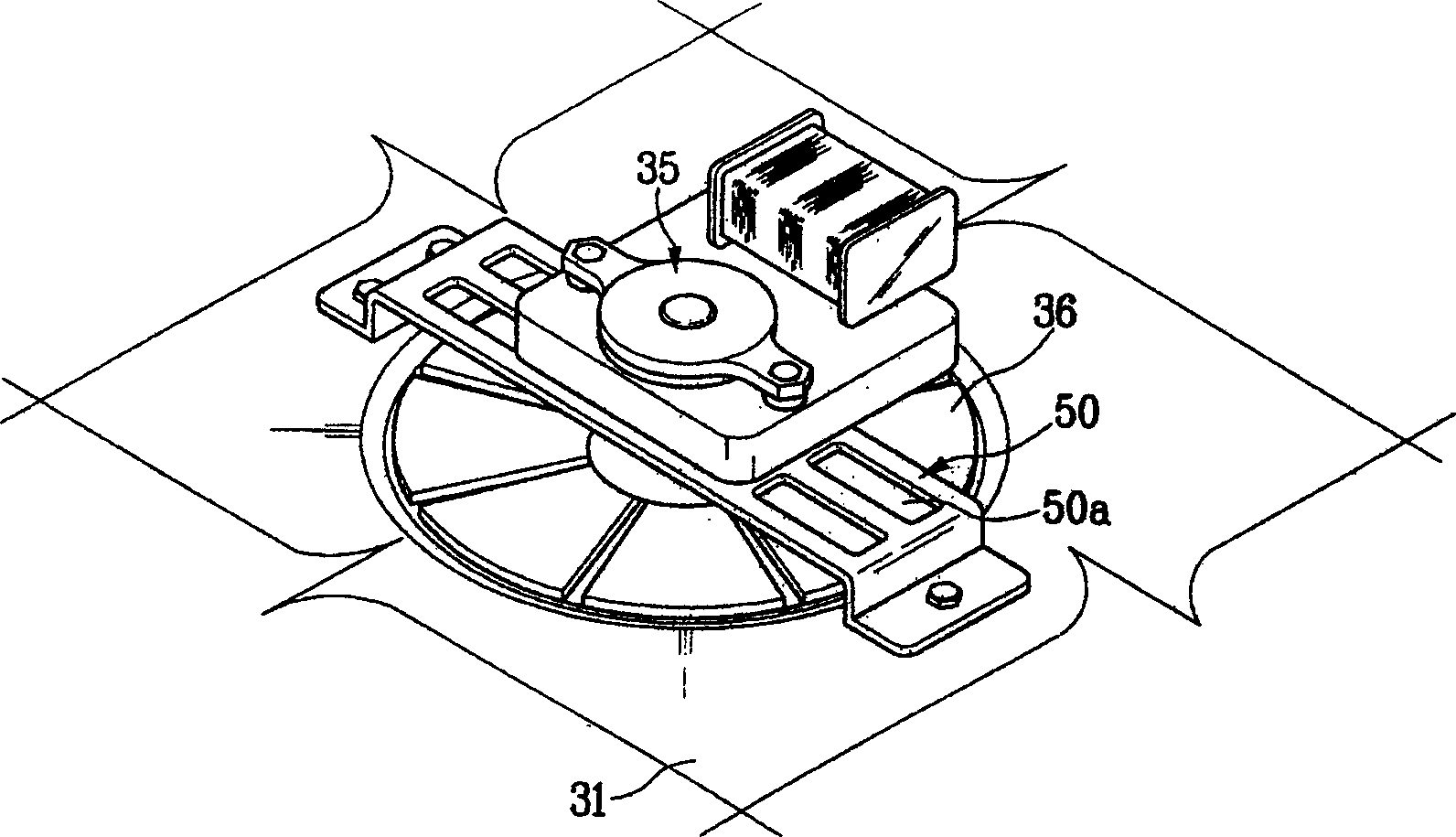

[0042] Figure 4 It is a horizontal cross-sectional view of a preferred embodiment of the internal structure of the convection microwave oven of the present invention.

[0043] Such as Figure 4 As shown, the convection type electronic microwave oven in the preferred embodiment of the present invention mainly includes: a microwave oven body 10, a cavity 20, an electronic accessory chamber 40, and a convection part.

[0044] The microwave oven body 10 forms the appearance of the microwave oven, and consists of a front panel 11 forming the front side of the microwave oven, a shell 12 forming the two sides and the upper side of the microwave oven, and a rear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com