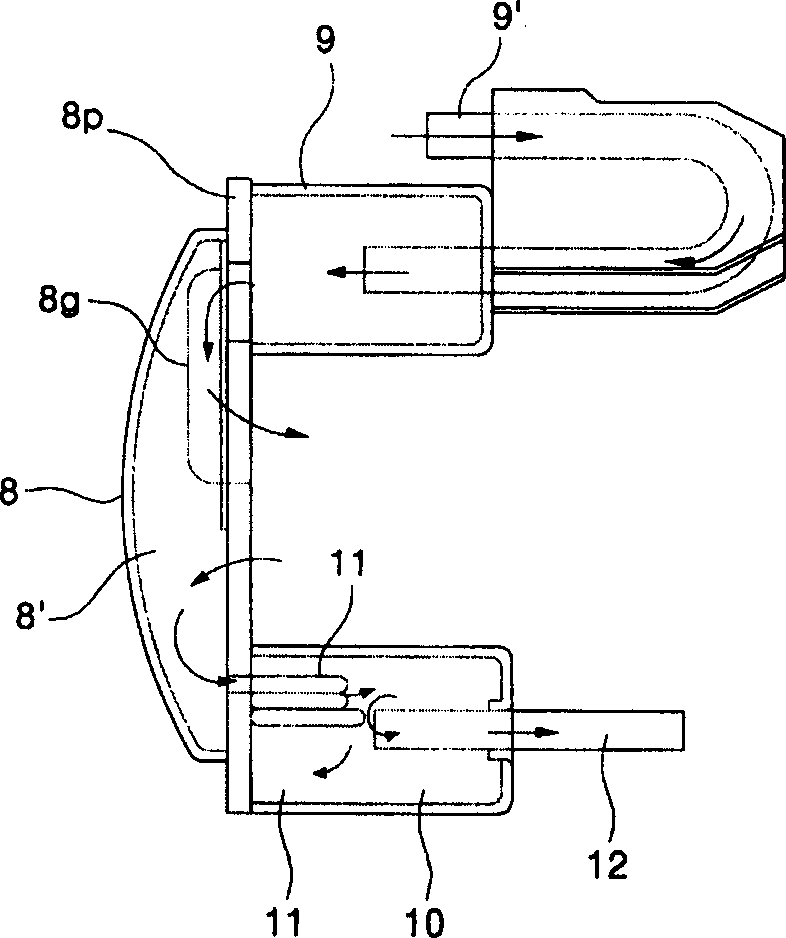

Top hood assembly of closed compressor

A compressor, a closed technology, applied in the field of compressors, can solve the problems of large vibration and noise, vibration of the discharge pipe 12, short passage, etc., achieve good pulsation and noise, and reduce noise and pulsation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0037] First, the process of compressing the working fluid by the compressor of the present invention will be described. When the motor unit 22 operates, the crankshaft 24 rotates. Under the action of the rotation of the crankshaft 24 , the eccentric member 25 performs a circular motion, and one end of the connecting rod 26 connected thereto moves together with the eccentric member 25 . The piston connected to the other end of the connecting rod 26 performs linear reciprocating motion inside the compression chamber of the cylinder 28 to compress the refrigerant.

[0038] The working fluid flows through the suction muffler 55 and is directed to the compression chamber. That is, the working fluid whose noise has been eliminated in the suction muffler 55 flows into the compression chamber under the control of the valve assembly 29 .

[0039] As ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com