Method for machining clutch shafts

The technology of a clutch shaft and processing method, which is applied in the processing field of the fourth-speed clutch shaft, can solve the problems of high raw material requirements, low yield rate, complex production process, etc., and achieve the effects of simple processing technology, long product life and simple process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

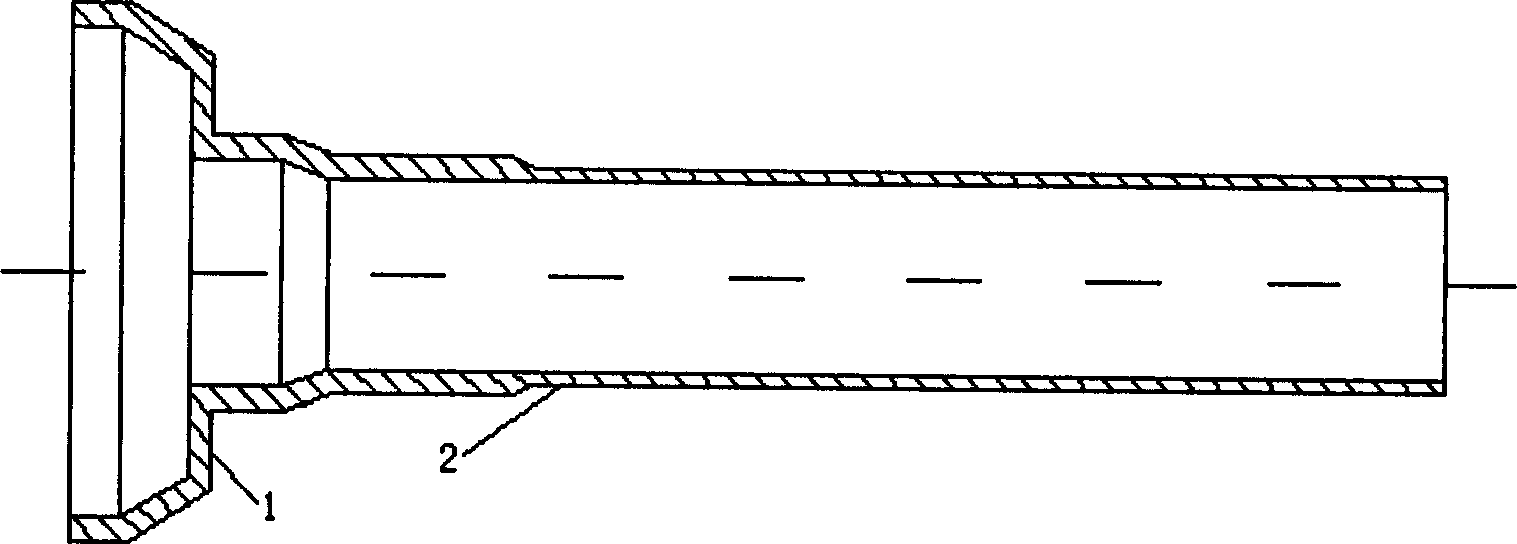

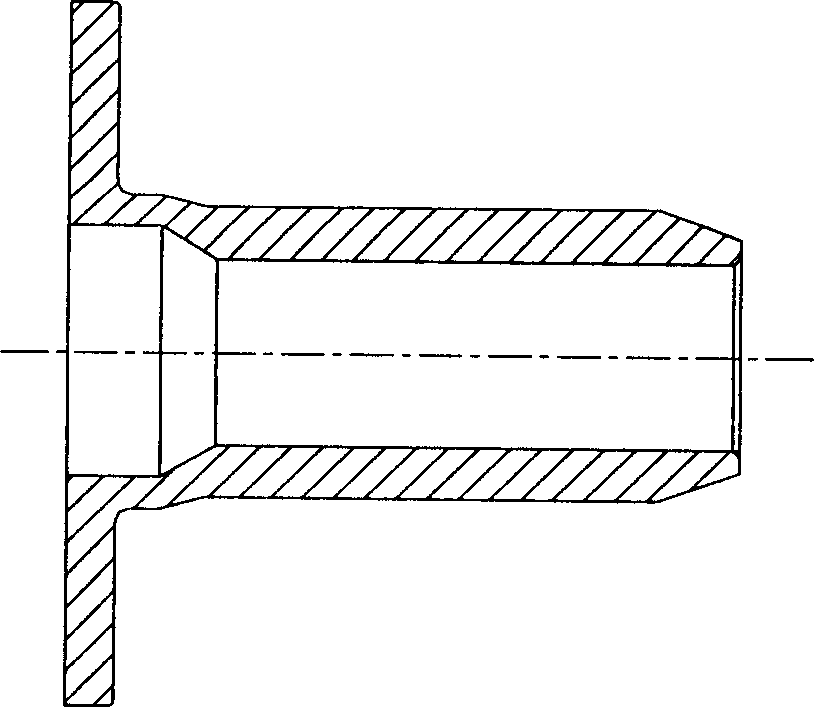

[0021] see figure 1 , it can be seen that the traditional clutch shaft includes a hub 1 and a shaft 2, and the joint part 3 between the hub 1 and the shaft 2 is connected by laser welding. see figure 2 , the clutch shaft obtained by the method of the present invention includes a hub 1 and a shaft 2, the hub and the shaft are an integral component and seamlessly connected.

[0022] see figure 2 , image 3 , Figure 4 with Figure 5 , the processing method of clutch shaft of the present invention comprises the steps:

[0023] a) will image 3 The shown blank is forged into a "T"-shaped short shaft; it is made of domestic material blanks through forging, drilling, heat treatment, and turning. The pressure during forging is 800 tons, and the drilling diameter is φ26.5±0.3. The hardness is HRB60-74.

[0024] b) Wheel hub forming: use cold spinning process to directly cold spin the head of the "T" shaped shaft into a hub; use CNC automatic 3-spinning roller precision spinn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com