Facial mounting machine

A technology for surface mounting machines and assembly blocks, applied in electrical components, electrical components, etc., can solve problems such as increasing the number of parts and equipment large-scale, to improve impact absorption, prevent component adsorption position deviation, and improve adsorption stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Preferred embodiments of the present invention will be described below with reference to the drawings.

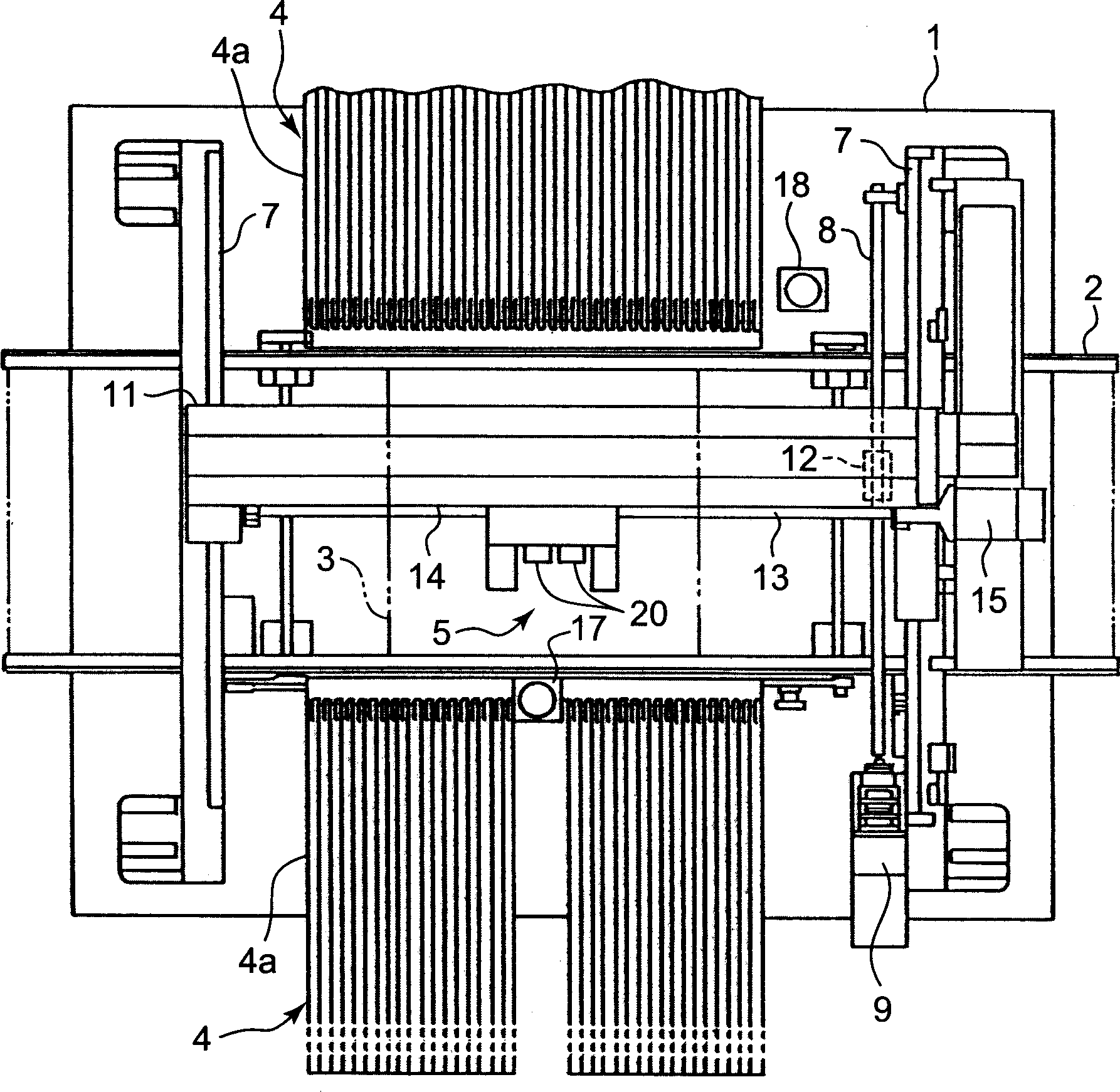

[0039] figure 1 The overall structure of the surface mounter according to the embodiment of the present invention is schematically shown. In this figure, a conveyor belt 2 constituting a conveyor line is provided on a base 1, and a printed circuit board 3 is conveyed on the conveyor belt 2 and stopped at a predetermined work position.

[0040] A component supply unit 4 is provided on the side of the conveyor belt 2 . Multiple rows of tape feeders 4 a are provided on this component supply unit 4 . Each tape feeder 4a draws out from a reel a paper tape containing and holding small electronic components such as ICs, transistors, and capacitors at predetermined intervals, and intermittently takes out the electronic components by the head unit 5 described later.

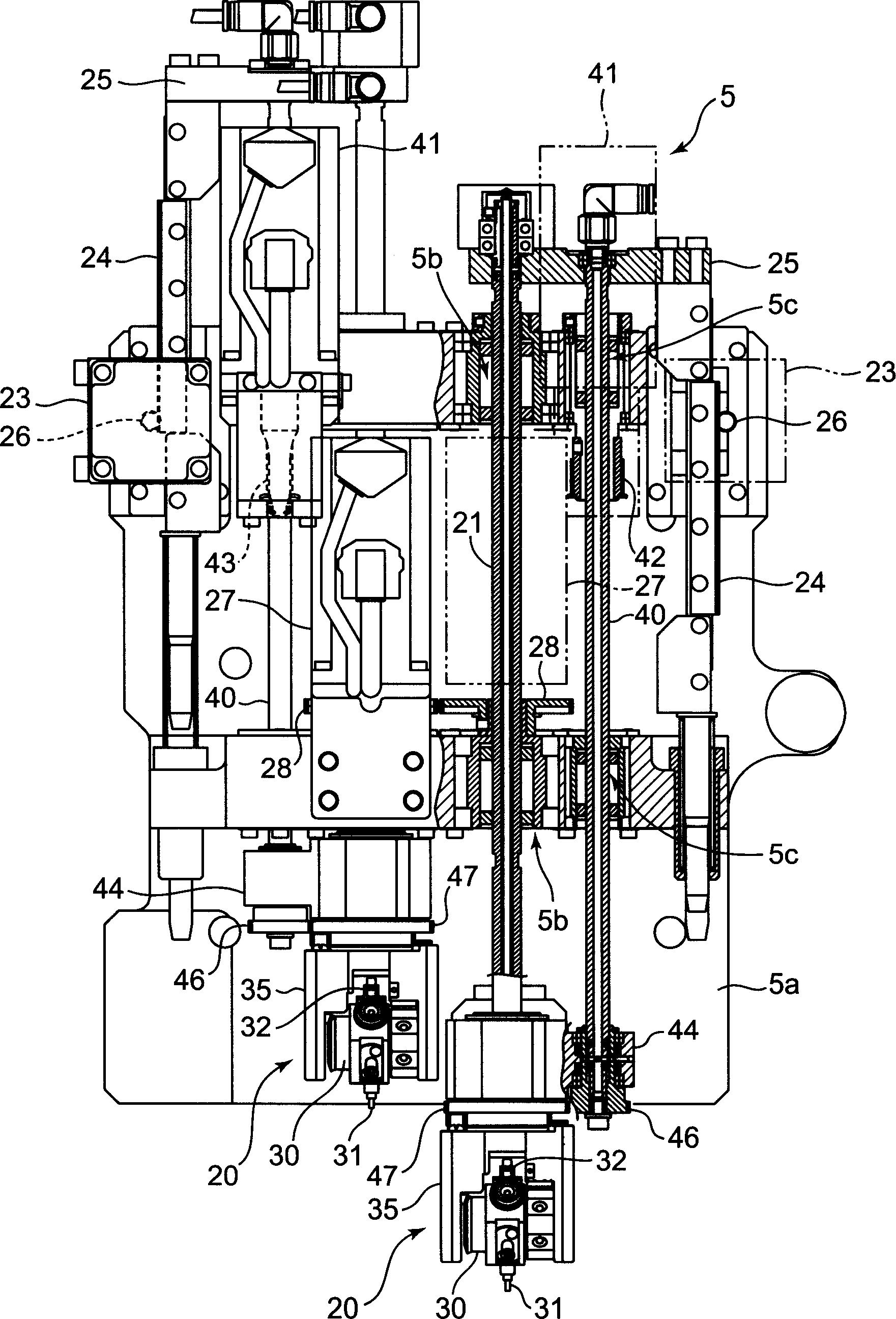

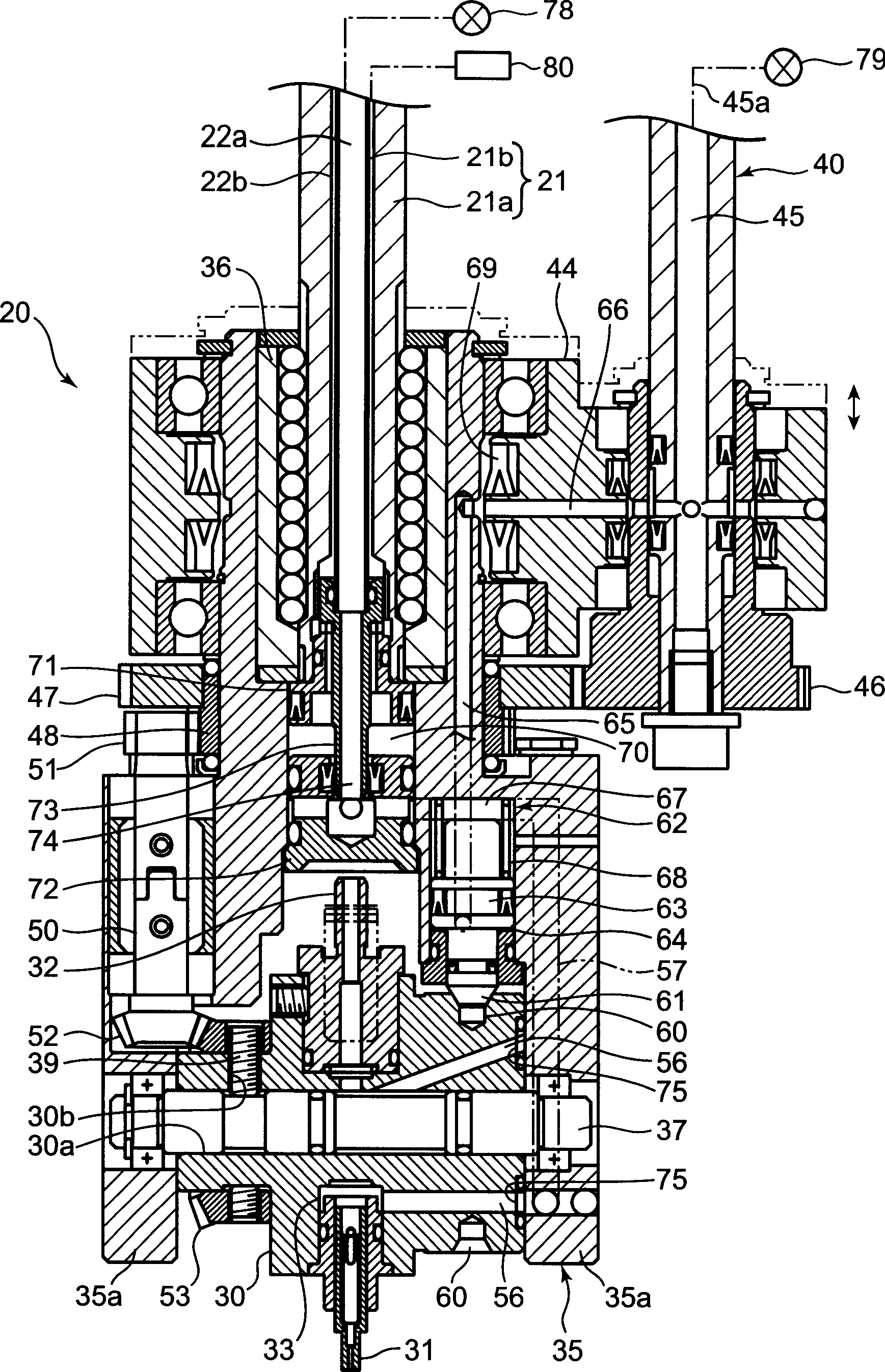

[0041] In addition, a head unit 5 for loading electronic components is provided above the above-mentioned ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com