Integral multi-oil-wedge tiltable bush hydrodynamic sliding bearing

A sliding bearing, integral technology, applied in sliding contact bearings, rotating bearings, bearings, etc., can solve the problems of inconvenient bearing installation, increased machine power loss, large vibration and noise, etc., to improve anti-vibration performance, reduce Consumable parts, the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

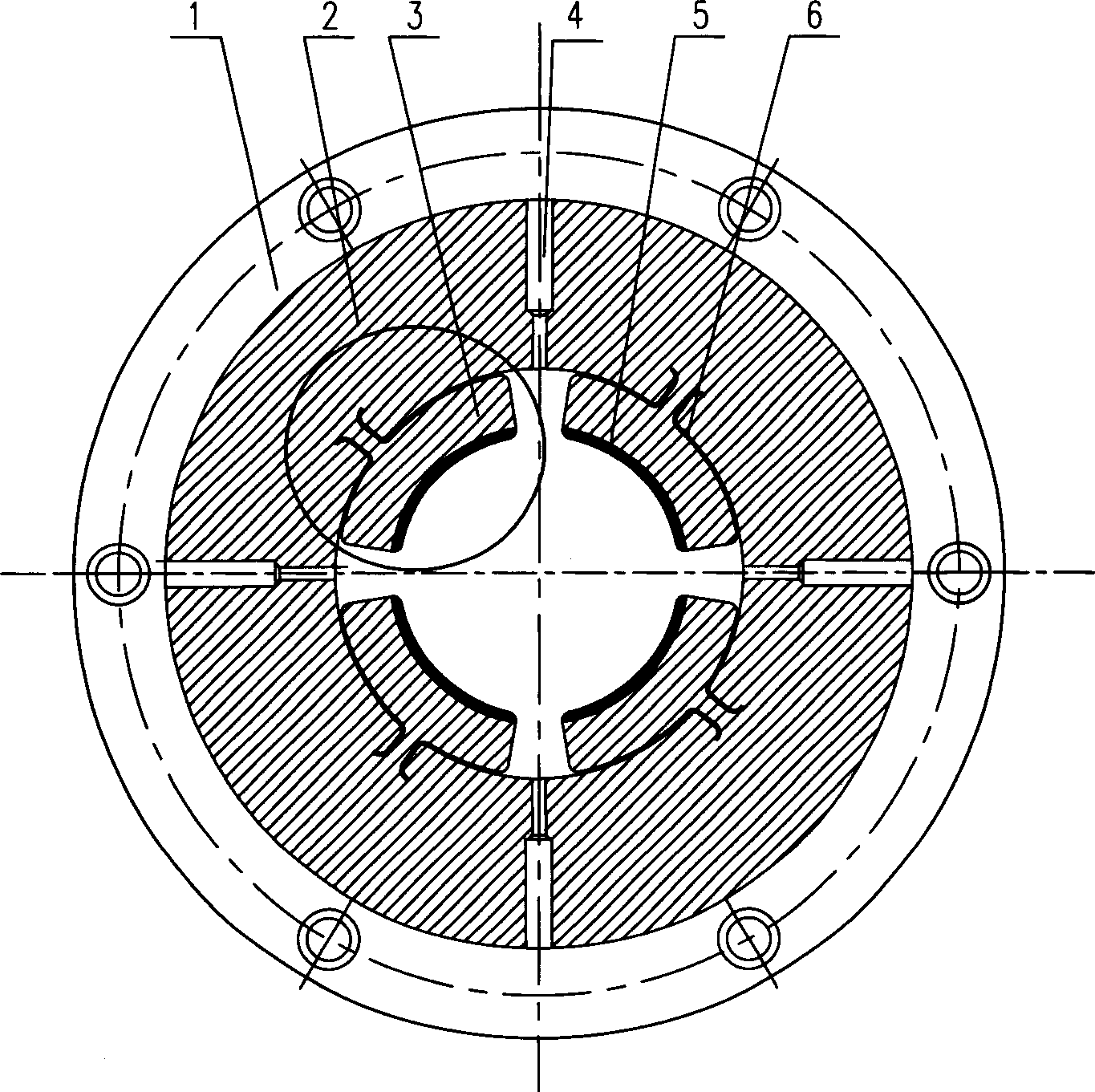

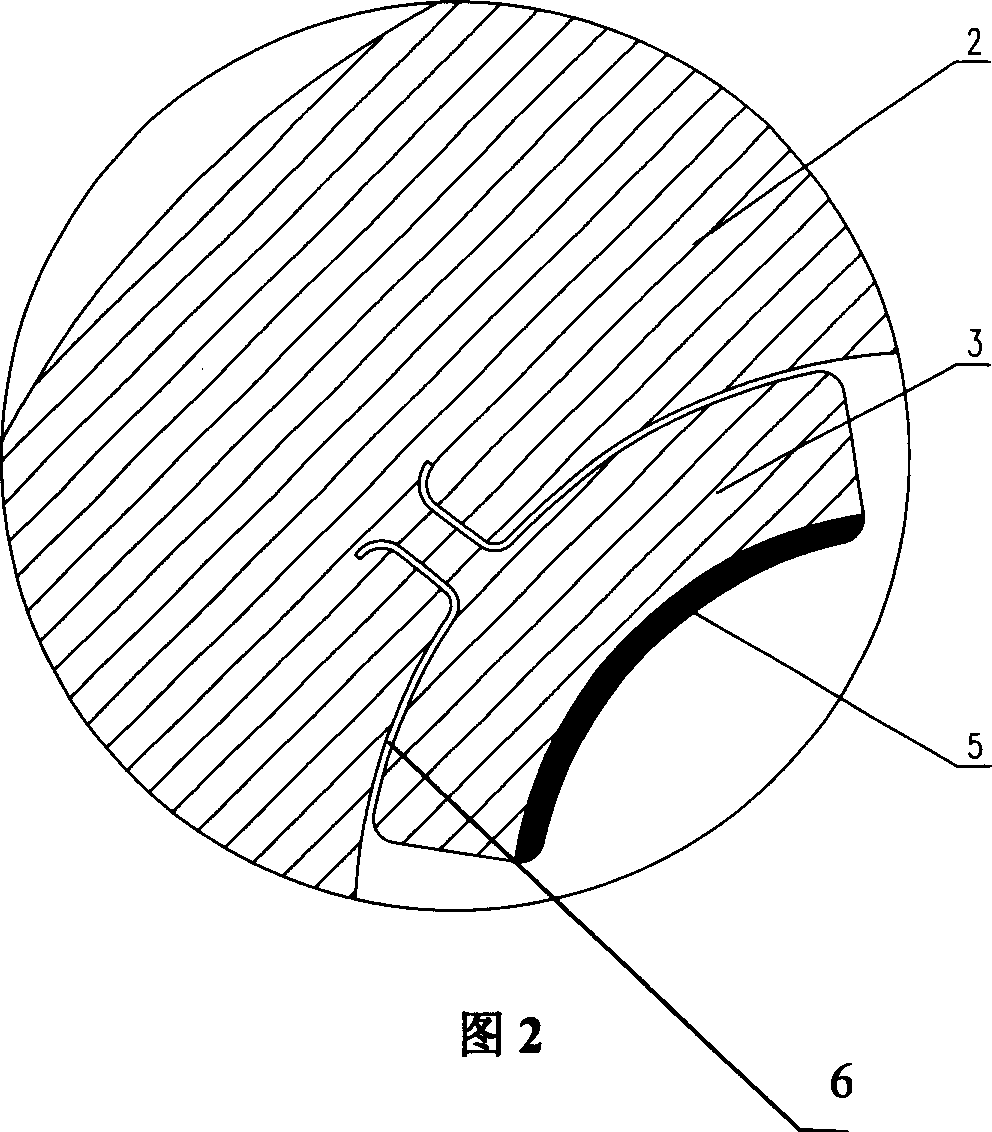

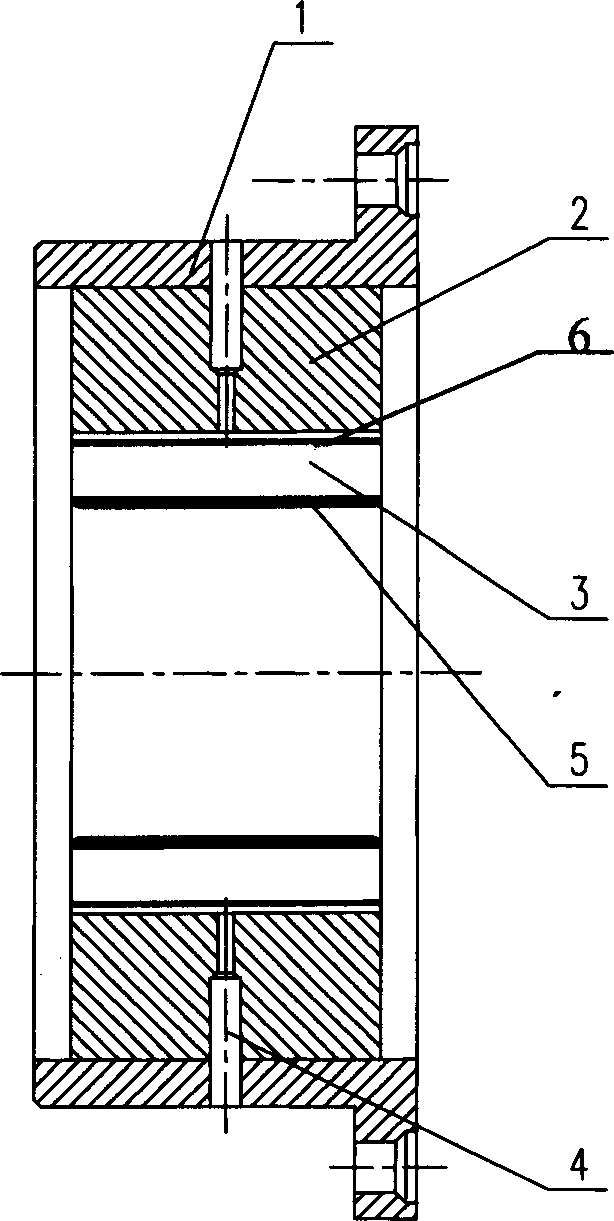

[0015] The device structure of the integral multi-oil wedge tilting pad dynamic pressure sliding bearing of the present invention is as follows: figure 1 As shown, the bearing seat 2 and the bearing bush 3 are integrated, the bearing seat 2 and the bearing bush 3 in the center are an integral structure processed by wire cutting technology, the bearing bush 3 is connected with the bearing seat 2 through the protrusion in the middle of the outer side, and the bearing bush 3. There is a gap 6 between the outer surface of both sides of the protrusion and the bearing seat 2. Wire cutting technology is used during processing. According to the design requirements, the gap 6 between the bearing seat and the bearing bush is precisely processed. The inner surface of the bearing bush 3 is covered with Babbitt alloy 5. The bearing seat 2 is hot-fitted int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com