High-pressure water jet drill bit capable of punching and cutting by switching of water pressure

A high-pressure water jet and punching technology, which is applied to drill bits, liquid/gas jet drilling, drilling equipment, etc., can solve problems such as single operation mode, complex structure, and no repeated switching, and achieve the effect of simplifying the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

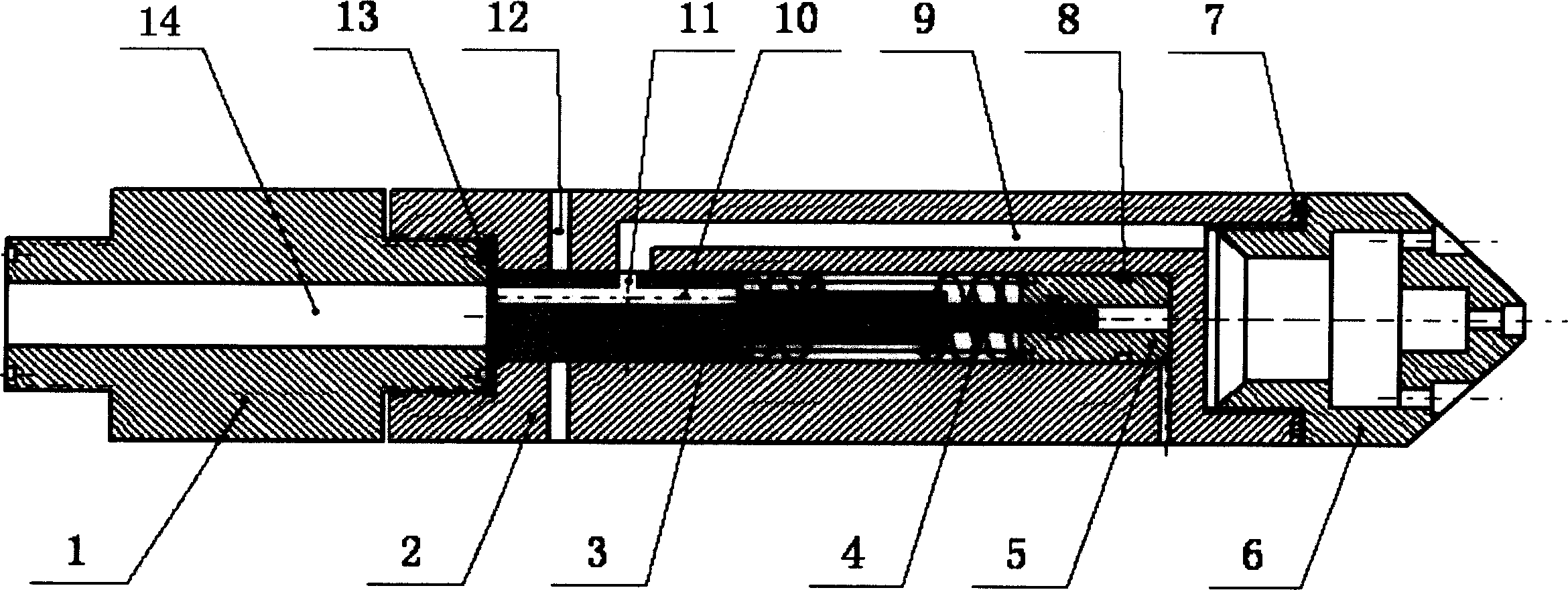

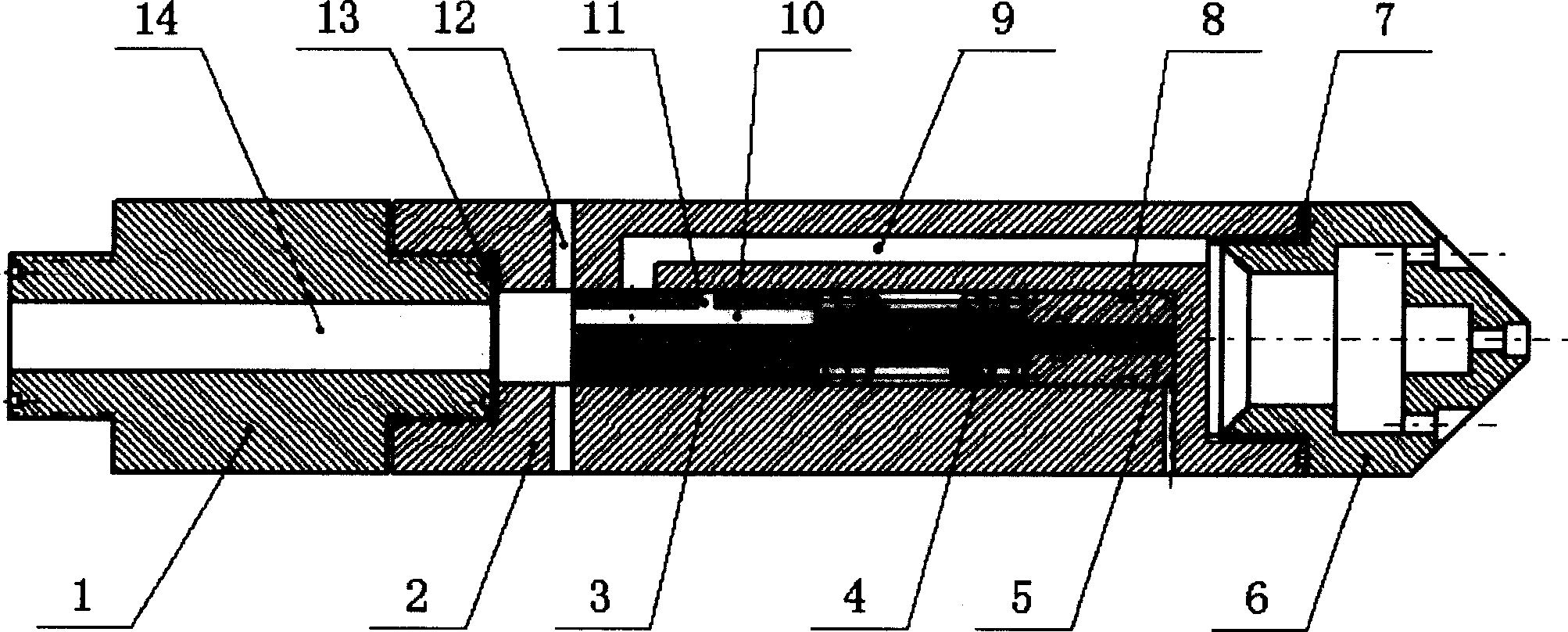

[0012] Such as figure 1 , 2 As shown, a high-pressure water jet drill bit capable of hydraulically switching punching and slotting includes a housing 2 and a nozzle 6 connected to the top of the housing. A drill core 3, a return spring 4, and a pressure regulating valve 5 are sequentially installed in the inner cavity of the housing. The drill core 3 is a stepped shaft structure with three different diameters. The shaft section with a large diameter is slidingly fitted with the inner cavity of the casing 2, and a diversion channel 10 and a vertical diversion hole 11 are arranged along the axis. The inner hole of the pressure regulating valve 5 is slidingly fitted, the return spring 4 is set in the middle section of the step shaft, the housing 2 is provided with a horizontal diversion channel 9 and a vertical diversion channel 12, and the tail of the housing 2 is installed with a positioning guide hole 14 Indenter 1.

[0013] The diameter of the guide hole 14 of the position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com