Colour ink-jet ink and its preparing method

A color and inkjet printing technology, which is applied in printing, ink, household utensils, etc., can solve the problems of environmental pollution, poor light resistance and water resistance, and reduce the life of nozzles, etc. fast time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] Preparation method, the steps are as follows:

[0025] 1) Take each component in proportion, stir and mix the colored nano light fast dye with deionized water to form a uniform color paste;

[0026] 2) Under stirring conditions, heat the color paste to 60-70°C and keep the temperature constant for 1.5-2 hours;

[0027] 3) Cool the color paste to normal temperature, add ethylene glycol, absolute ethanol and glycerin, and stir evenly;

[0028] 4) Put it into a multi-stage filter, and filter it at least three times under a pressure of 1.5-2Kg to obtain a color jet printing ink.

Embodiment 1、2

[0029] Examples 1 and 2, the color paste was heated to 60°C, kept at a constant temperature for 2 hours, and filtered three times under a pressure of 1.5Kg.

Embodiment 3

[0030] Examples 3 and 4, the color paste was heated to 70°C, kept at a constant temperature for 1.5 hours, and filtered three times under a pressure of 2Kg.

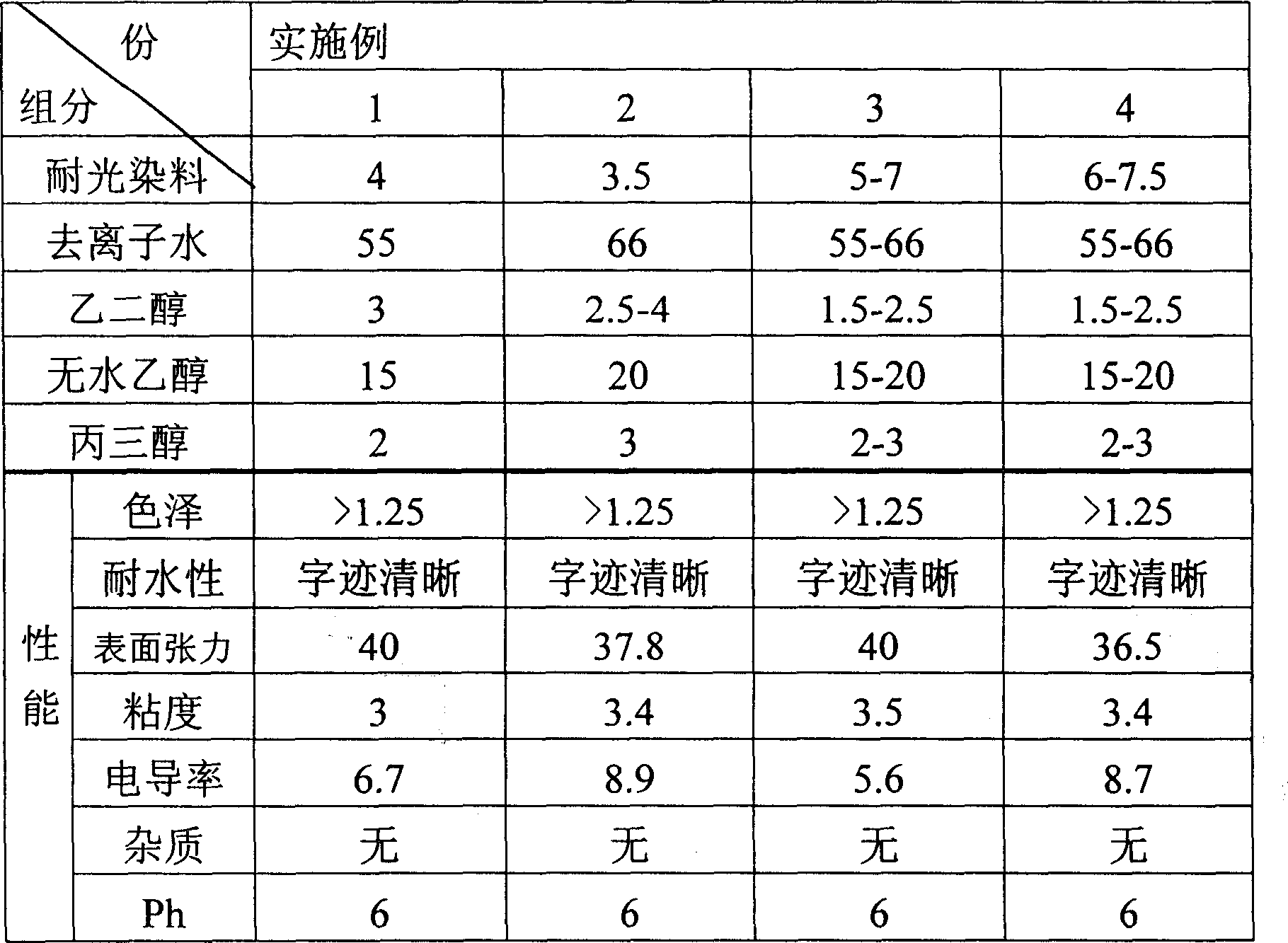

[0031] Table 1

[0032]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com