Yarn heater and its use

A yarn heater and yarn technology, applied in textiles and papermaking, etc., can solve problems such as quality degradation and yarn breakage, and achieve the effects of avoiding yarn balloons, preventing yarn breakage, and minimizing downtime

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

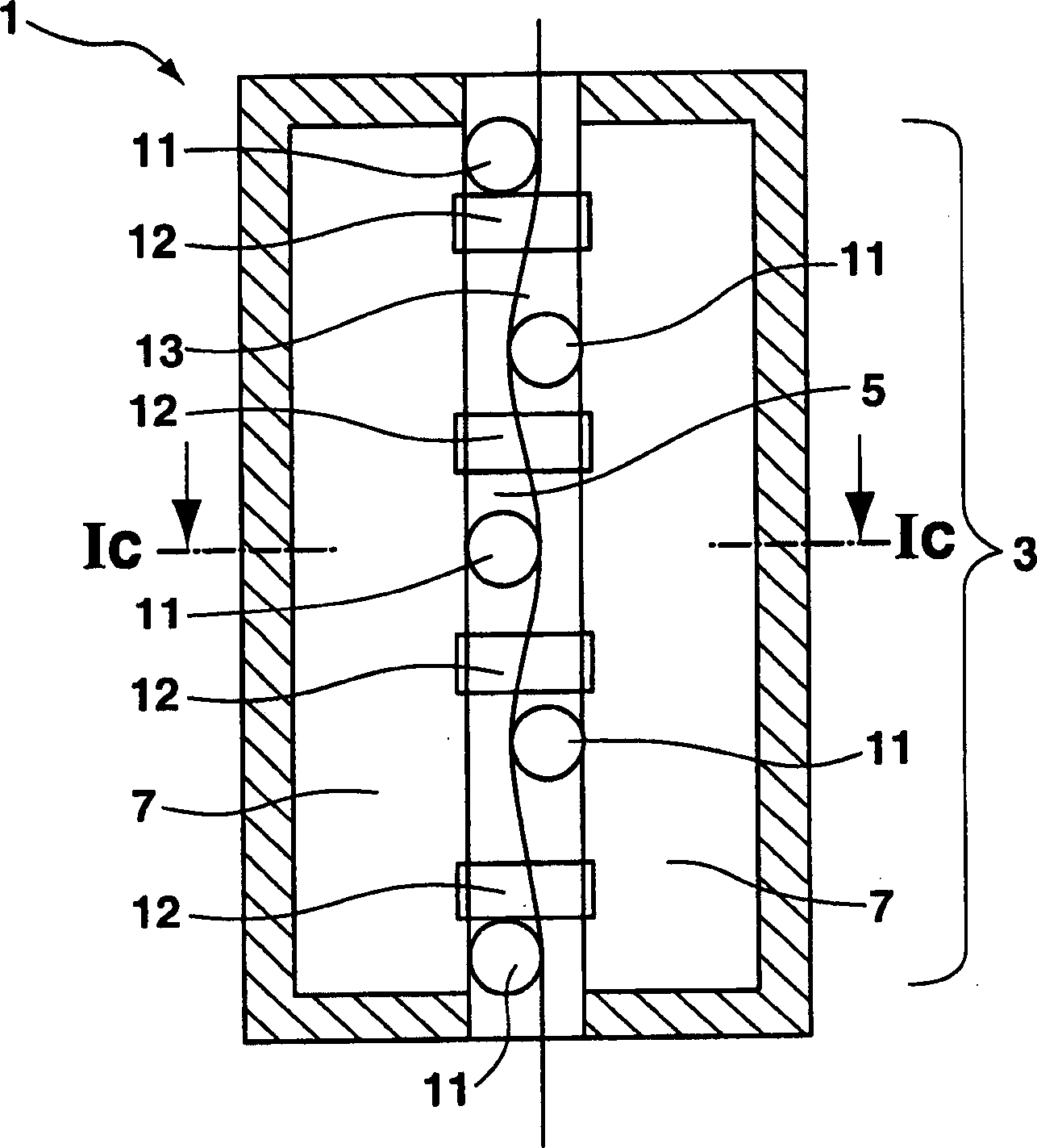

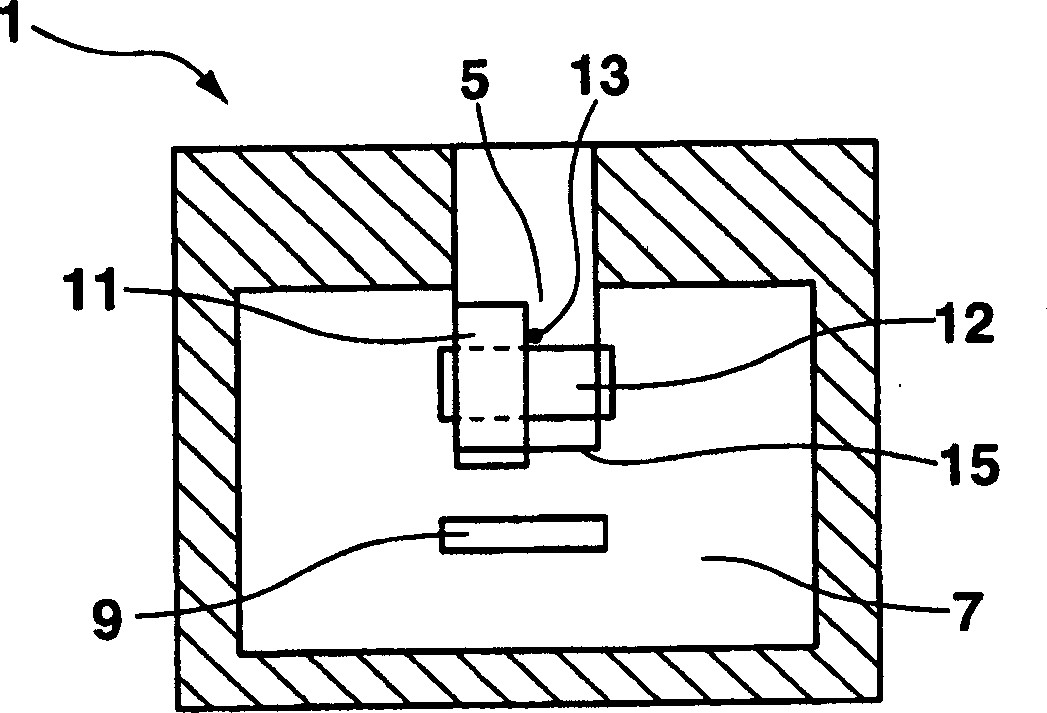

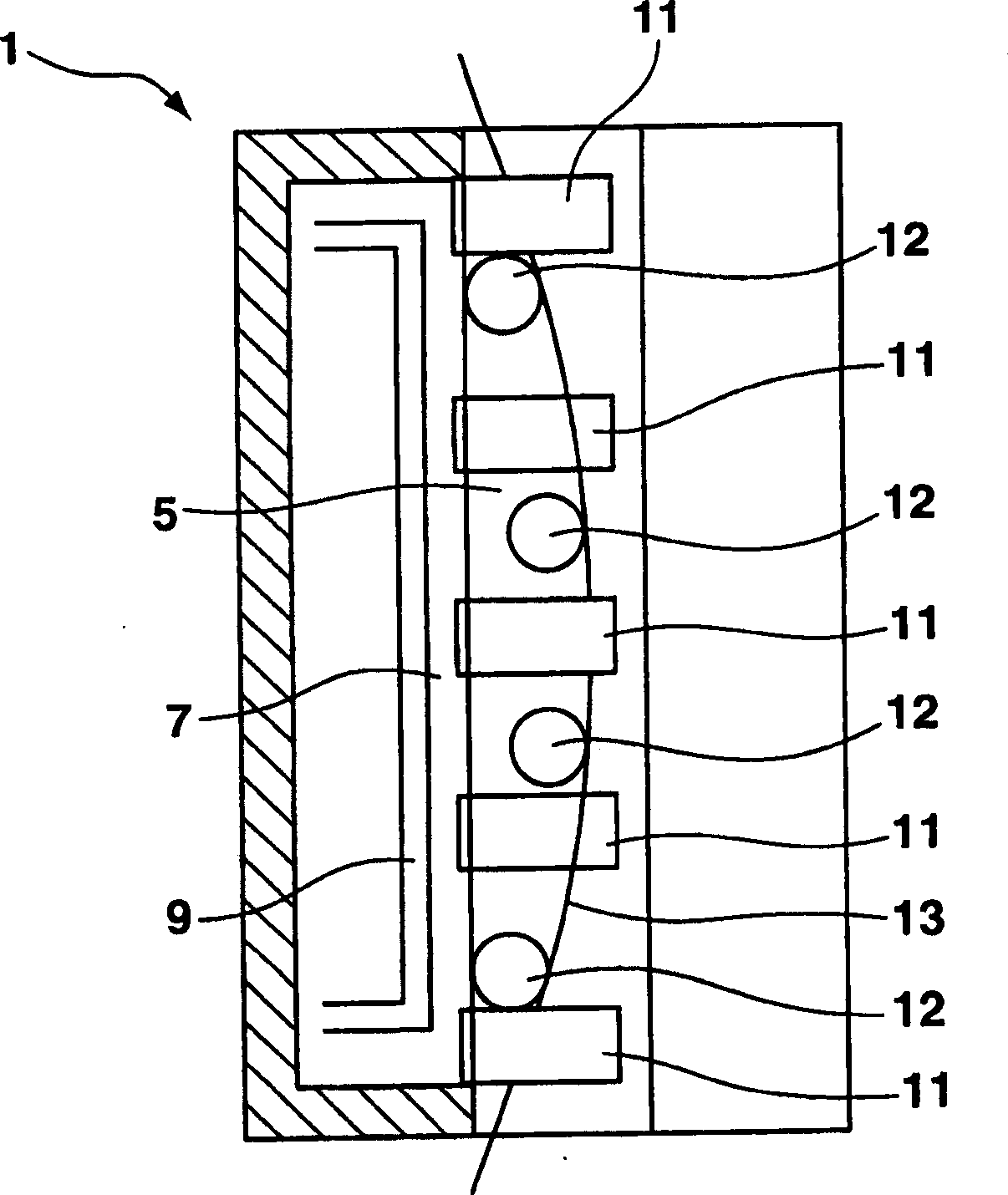

[0019] The subject matter according to the invention is only schematically shown in the drawings and should therefore not be understood as being to scale. The individual components of the subject matter according to the invention are shown in the figures so that their structure can be clearly shown.

[0020] Figures 1a to 1c Three mutually perpendicular sections of a yarn heater 1 according to the invention are shown. The yarn heater 1 according to the invention has a heating zone 3 with a yarn channel 5 . A heating wall 7 arranged on the yarn channel 5 can be heated by a heating device 9 . The heating device 9 comprises, for example, a heating coil which can be heated by means of an electric current. The temperature of the heating wall 7 can be adjusted by means of a regulating module, not shown in the figure, for example by regulating the intensity of the current flowing through the heating coils. The yarn guides 11 , 12 are arranged in the yarn channel 5 . These threa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com