Electric slipform concrete lining machine

A technology for concrete and lining machines, which is applied in construction, building structure, construction material processing, etc., can solve the problems of large maintenance workload, long installation and disassembly cycle, huge equipment, etc., and achieves convenient installation and removal, superior and reliable performance. , the effect of less maintenance work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

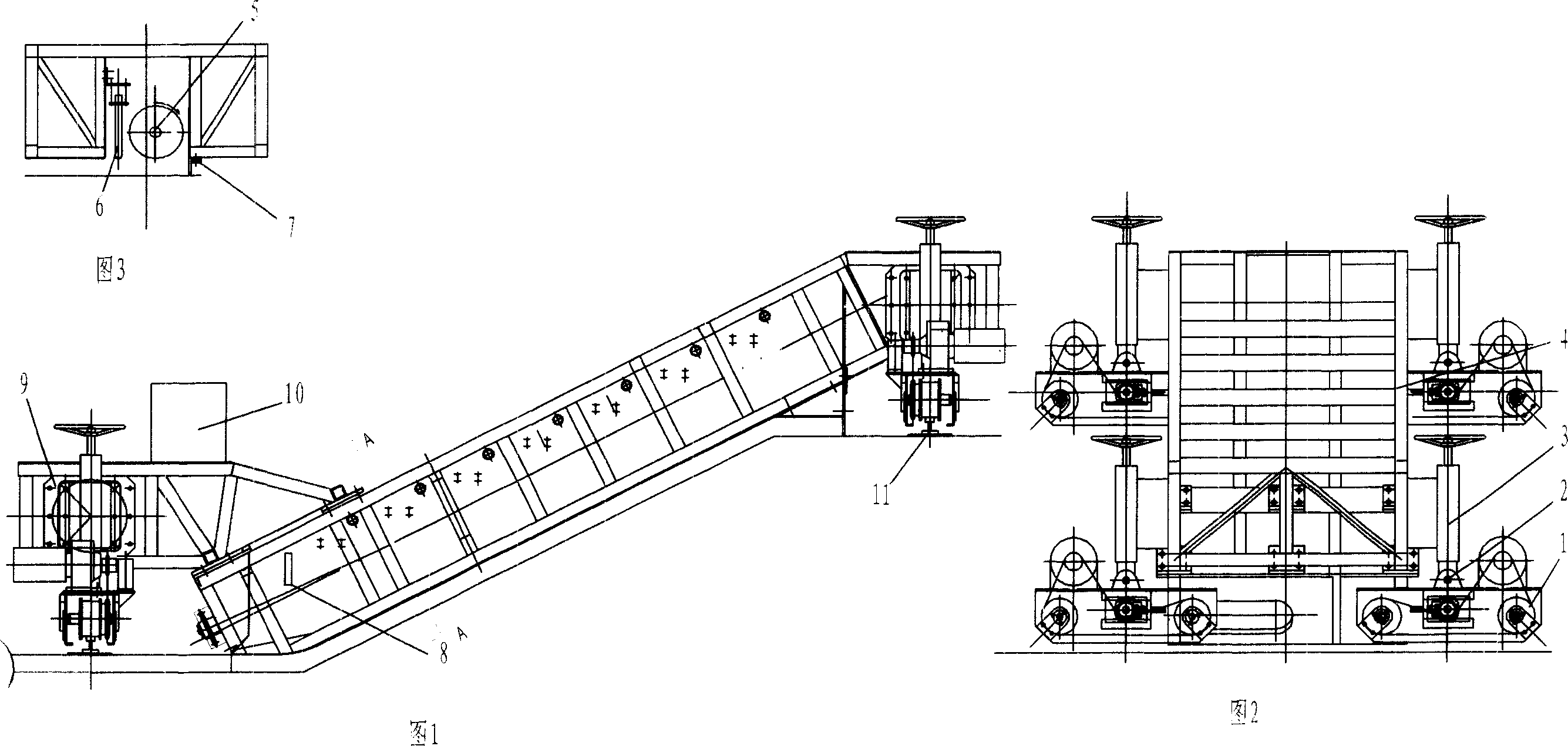

[0029] As shown in Figure 1, Figure 2, Figure 3, Figure 4 As shown, the silo frame structure 4 of this embodiment is used as the main structure, and the traveling mechanism walks along the laid guide rail 11, and the four supporting connecting plates 9 are connected by bolts, and the supporting connecting plates are connected by bolts to the spiral lifting adjustment device 3, and the supporting connecting plates are connected by the supporting pins. 2. Connected and supported on the four two-wheel drive wheel sets 1; the electric high-frequency vibrating device 6 is connected by bolts 53 on the rear baffle plate 36 of the silo, and several sets are set in the silo. Rods and a set of straight electric high-frequency vibrating rods installed horizontally inserted into the silo by bolts on the slope top canal shoulder formwork 31; The upper part of the lower left silo is provided with a material level gauge 8, the material distribution device 5 is installed on the silo frame str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com