Method and device for machining composite parts formed from a carrier device and a stamping pad

A technology of processing equipment and supporting devices, applied in metal processing equipment, welding equipment, laser welding equipment, etc., can solve the problems of inability to individually adapt to special requirements, impossible to automate the production of multi-color and personalized design, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] First of all, it is provided that in the different embodiments described, the same parts use the same symbols or the same component symbols, wherein the disclosed content contained in the entire description can be transferred to the same symbols with the same symbols or the same component symbols. part. Positional indications selected in the description, such as top, bottom, side, etc., refer to directly illustrated representations and can be sensibly transferred to the new position in the event of a position change. Furthermore, individual features or combinations of features of the different exemplary embodiments shown and described represent individual inventions or solutions according to the invention.

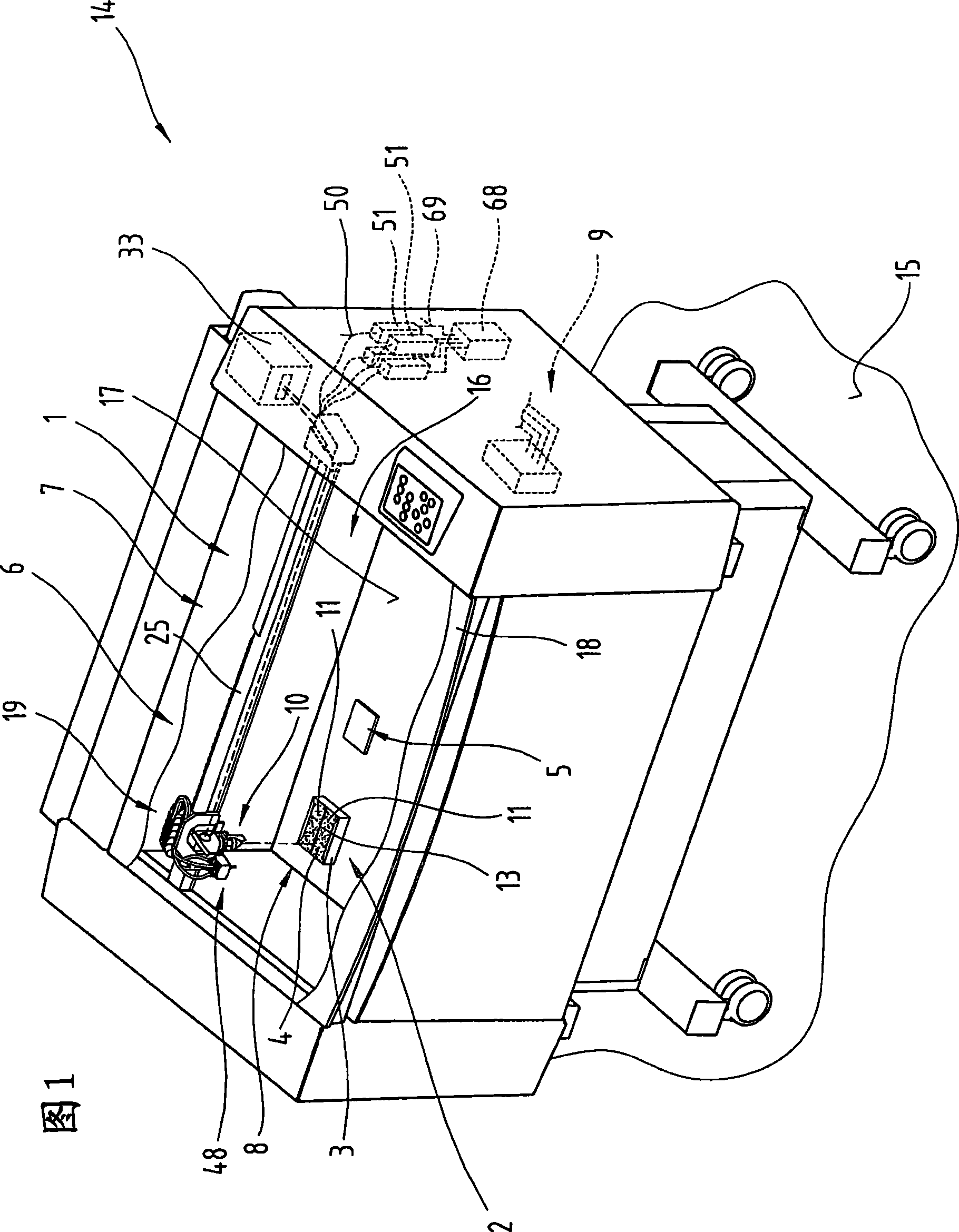

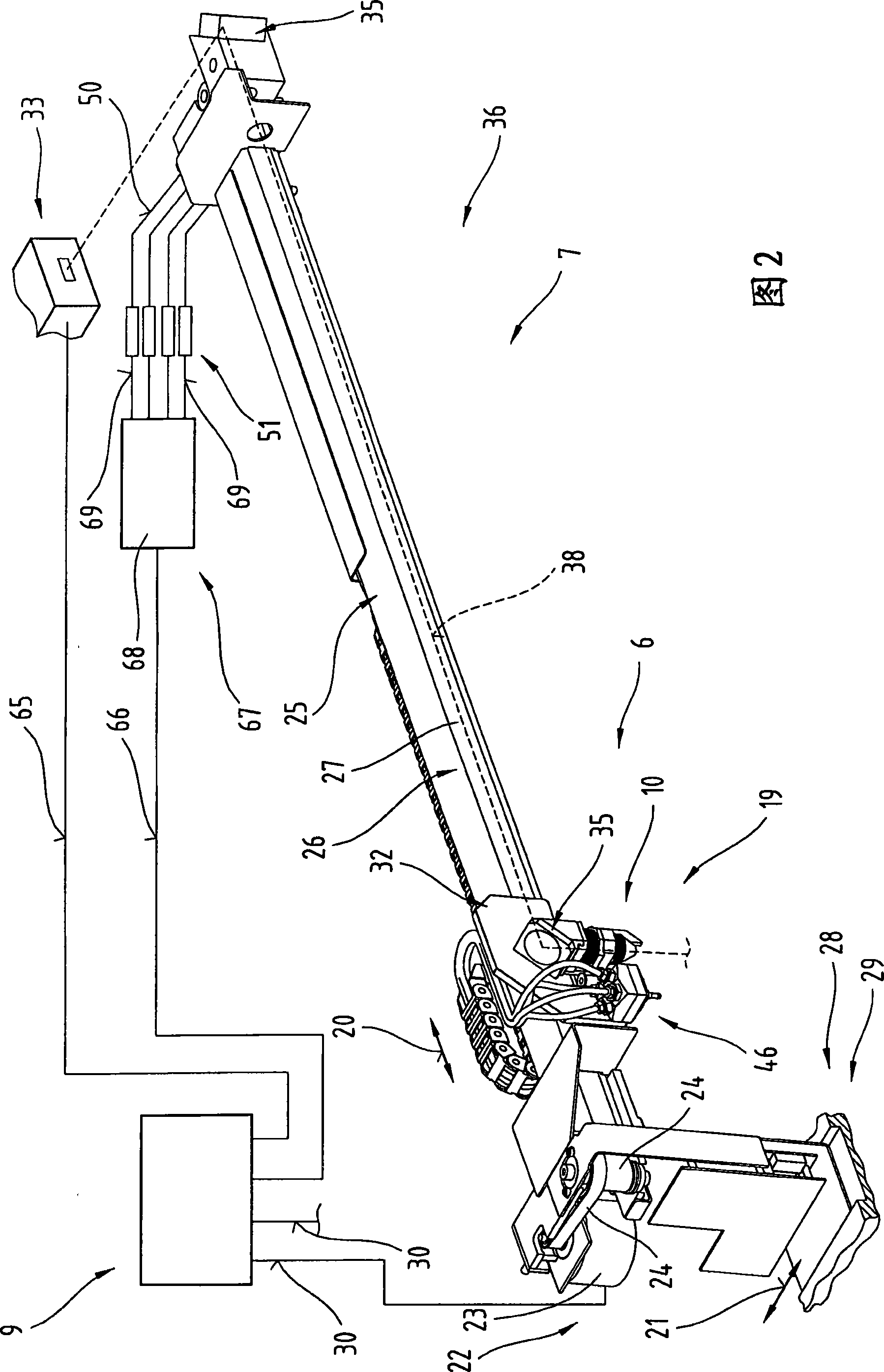

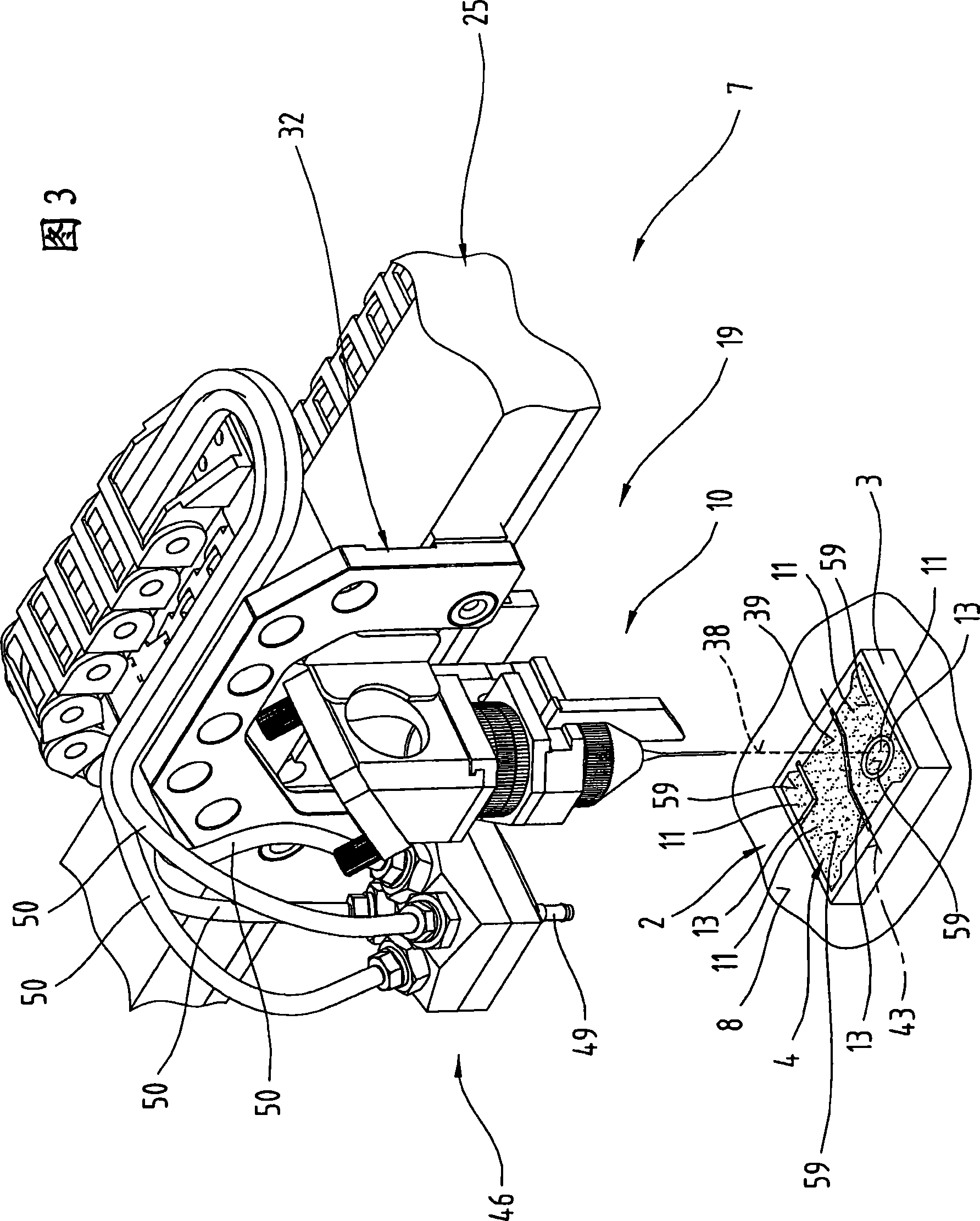

[0042] figure 1 In the middle is a processing device 1 according to the invention for processing at least one assembly 2, which is composed of at least one support device 3, in particular a printing pad holder, and a printing pad 4, where the processing device 1 ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com