Electronic controlled valve arrangement

A valve device, electronic control technology, applied in the direction of brakes, etc., can solve problems such as damage to the exhaustability of the braking system, and achieve the effects of avoiding blockage, high adjustment accuracy, and reliable exhaustability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

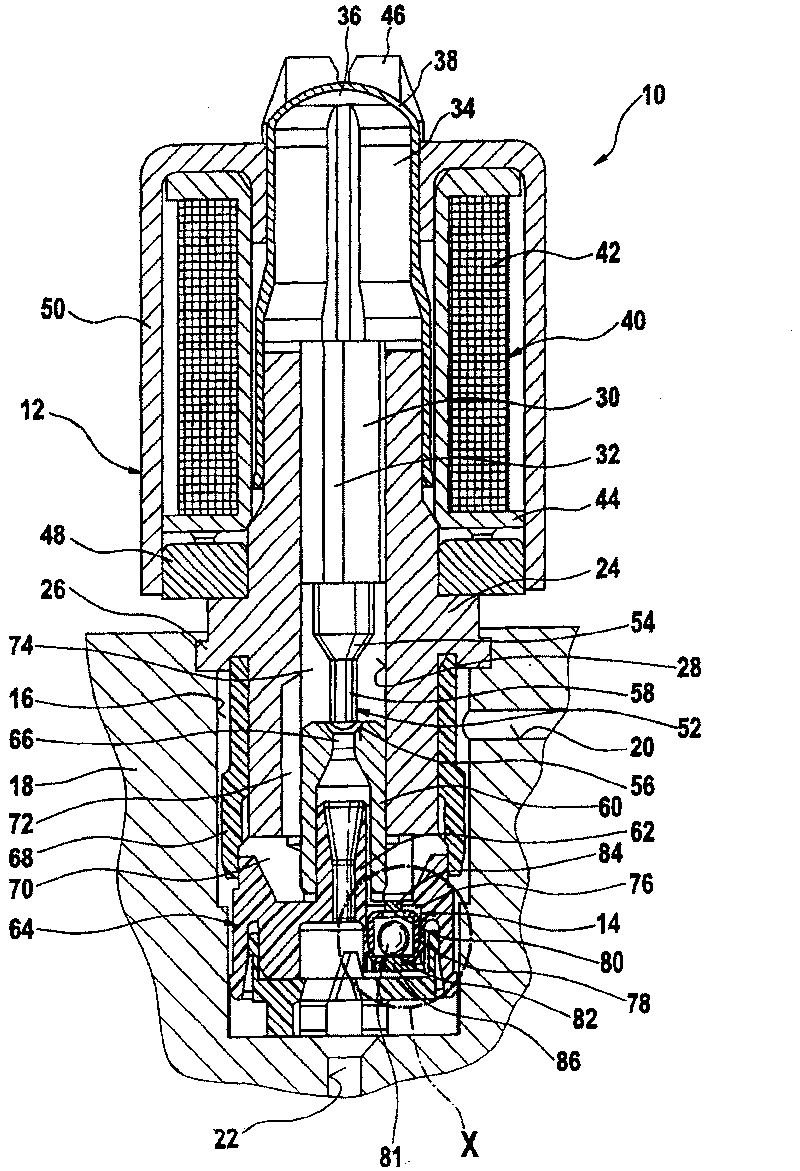

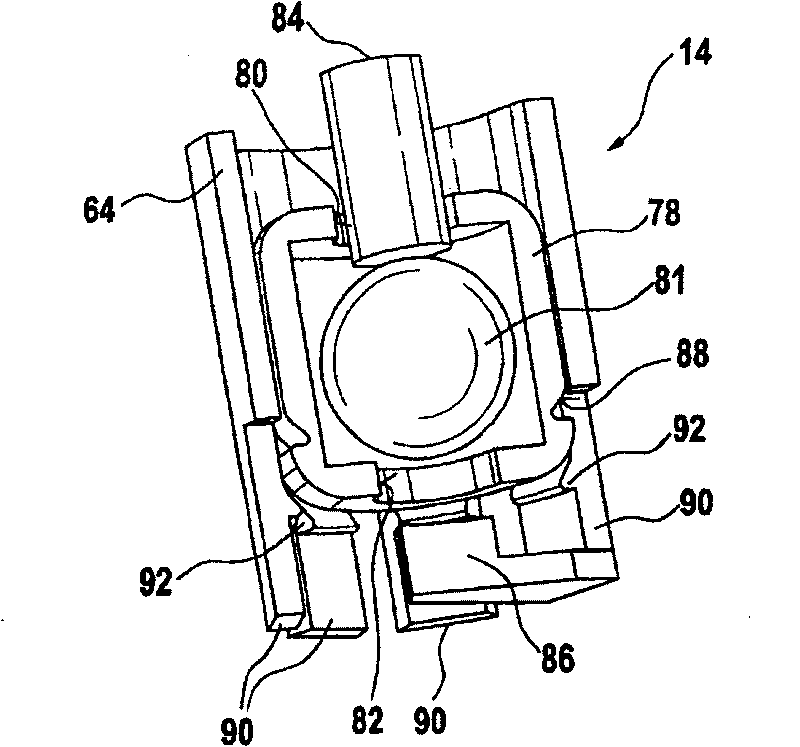

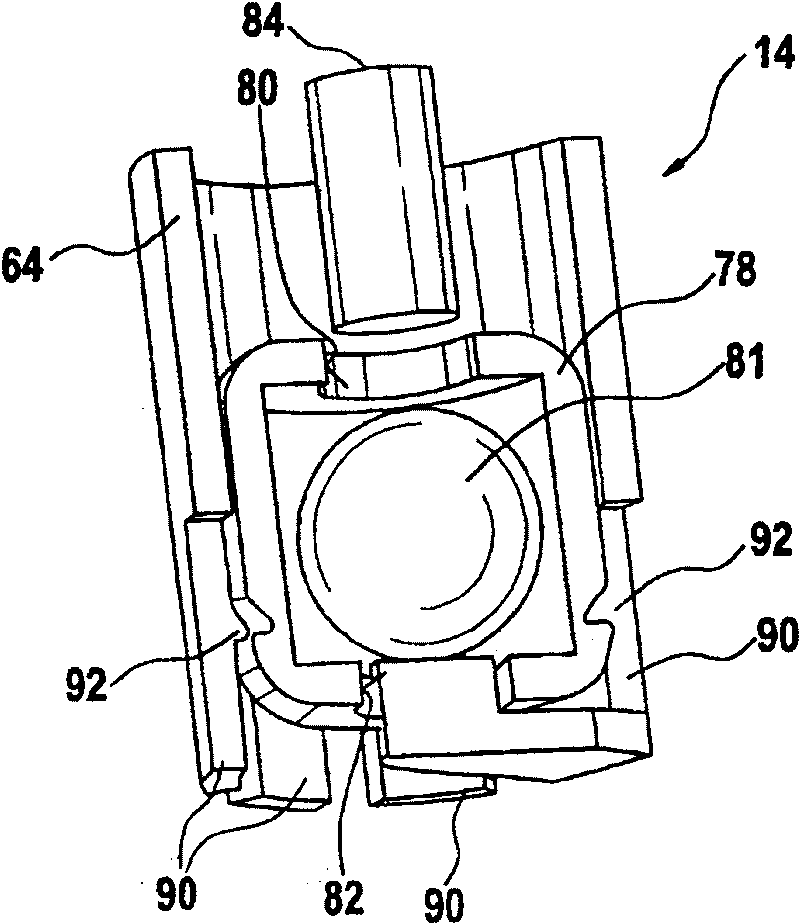

[0016] figure 1 The valve arrangement 10 shown consists of a solenoid valve 12 in which a non-return valve 14 is integrated. The valve device 10 is partly inserted in a mounting chamber 16 of a valve body 18 of a so-called hydraulic unit and is fixed therein in a form-fitting manner by pressing the material of the valve body 18 . Pressure medium channels 20 , 22 are provided in the valve body 18 , which open into the installation cavity 16 of the valve unit 10 for connection to the valve device 10 . A pressure medium channel 20 arranged horizontally in the housing forms the inlet, a vertically arranged pressure medium channel 22 forms the outlet of the valve device 10 . Both pressure medium channels 20 , 22 are sealed against each other with the valve unit 10 installed and sealed against the environment.

[0017] The valve device 10 also includes a valve seat body 24 . In this case it is preferably a pivoting part made of metal, which has a turned radial flange 26 for pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com