Electric polymer and preparation method

A technology of conductive polymers and polymer materials, applied in the field of conductive polymers and their preparation, can solve the problems of carbon nanotubes being easily broken and losing electrical conductivity, and achieve the effects of low cost, improved electrical conductivity, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

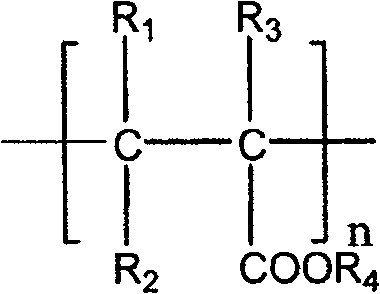

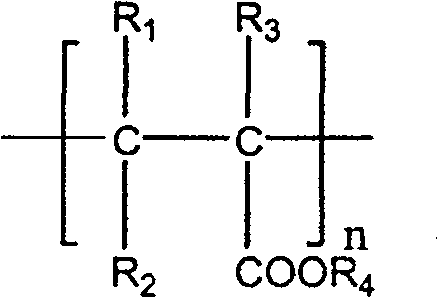

Method used

Image

Examples

Embodiment 1

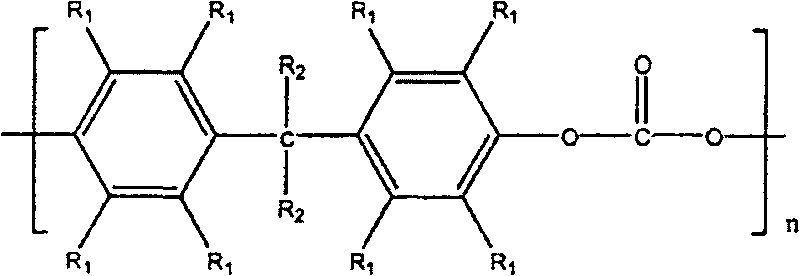

[0043] 1. Weigh 40 milligrams of single-walled carbon nanotubes (the diameter of single-walled carbon nanotubes is about 1.0 nanometers, and the length is about 2.5 microns) with an analytical balance, and put them in a 50-ml glass container with an accurate scale, and add 20 ml Dichloromethane organic solvent was vibrated by ultrasonic to form 20 ml of uniformly dispersed dichloromethane suspension containing carbon nanotubes.

[0044] 2. Weigh 200 mg of polybisphenol A carbonate with an analytical balance and put it in a 20 ml covered glass container, add 5 ml of dichloromethane organic solvent to dissolve, and make it fully dissolve to form transparent dichloromethane polybisphenol A carbonate solution. Use a pipette to accurately transfer 1.0 ml of uniformly dispersed dichloromethane suspension containing carbon nanotubes to a transparent dichloromethane polybisphenol A carbonate solution, and then use magnetic stirring and ultrasonic vibration for several minutes to make ...

Embodiment 2

[0048] 1. Weigh 40 milligrams of single-walled carbon nanotubes (the diameter of single-walled carbon nanotubes is about 1.0 nanometers, and the length is about 2.5 microns) with an analytical balance, and put them in a 50-ml glass container with an accurate scale, and add 20 ml Dichloromethane organic solvent was vibrated by ultrasonic to form 20 ml of uniformly dispersed dichloromethane suspension containing carbon nanotubes.

[0049]2. Weigh 200 mg of polybisphenol A carbonate with an analytical balance and put it in a 20 ml covered glass container, add 5 ml of dichloromethane organic solvent to dissolve, and make it fully dissolve to form transparent dichloromethane polybisphenol A carbonate solution. Use a pipette to accurately transfer 2.0 ml of uniformly dispersed dichloromethane suspension containing carbon nanotubes to a transparent dichloromethane polybisphenol A carbonate solution, and then use magnetic stirring and ultrasonic vibration for several minutes to make i...

Embodiment 3

[0053] 1. Weigh 40 milligrams of single-walled carbon nanotubes (the diameter of single-walled carbon nanotubes is about 1.0 nanometers, and the length is about 2.5 microns) with an analytical balance, and put them in a 50-ml glass container with an accurate scale, and add 20 ml Dichloromethane organic solvent was vibrated by ultrasonic to form 20 ml of uniformly dispersed dichloromethane suspension containing carbon nanotubes.

[0054] 2. Weigh 100 mg of polybisphenol A carbonate with an analytical balance and put it in a 20 ml covered glass container, add 3 ml of dichloromethane organic solvent to dissolve it, and make it fully dissolve to form transparent dichloromethane polybisphenol A carbonate solution. Use a pipette to accurately transfer 5.0 ml of uniformly dispersed dichloromethane suspension containing carbon nanotubes to a transparent dichloromethane polybisphenol A carbonate solution, and then use magnetic stirring and ultrasonic vibration for several minutes to ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com