Automobile top structure

A technology for automobiles and roofs, which is applied to the superstructure, superstructure sub-assemblies, motor vehicles, etc., can solve the problems of reduced interior space, increased cost and weight, etc., and achieves spacious interior space, reduced cost and weight. , to ensure the effect of the interior space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

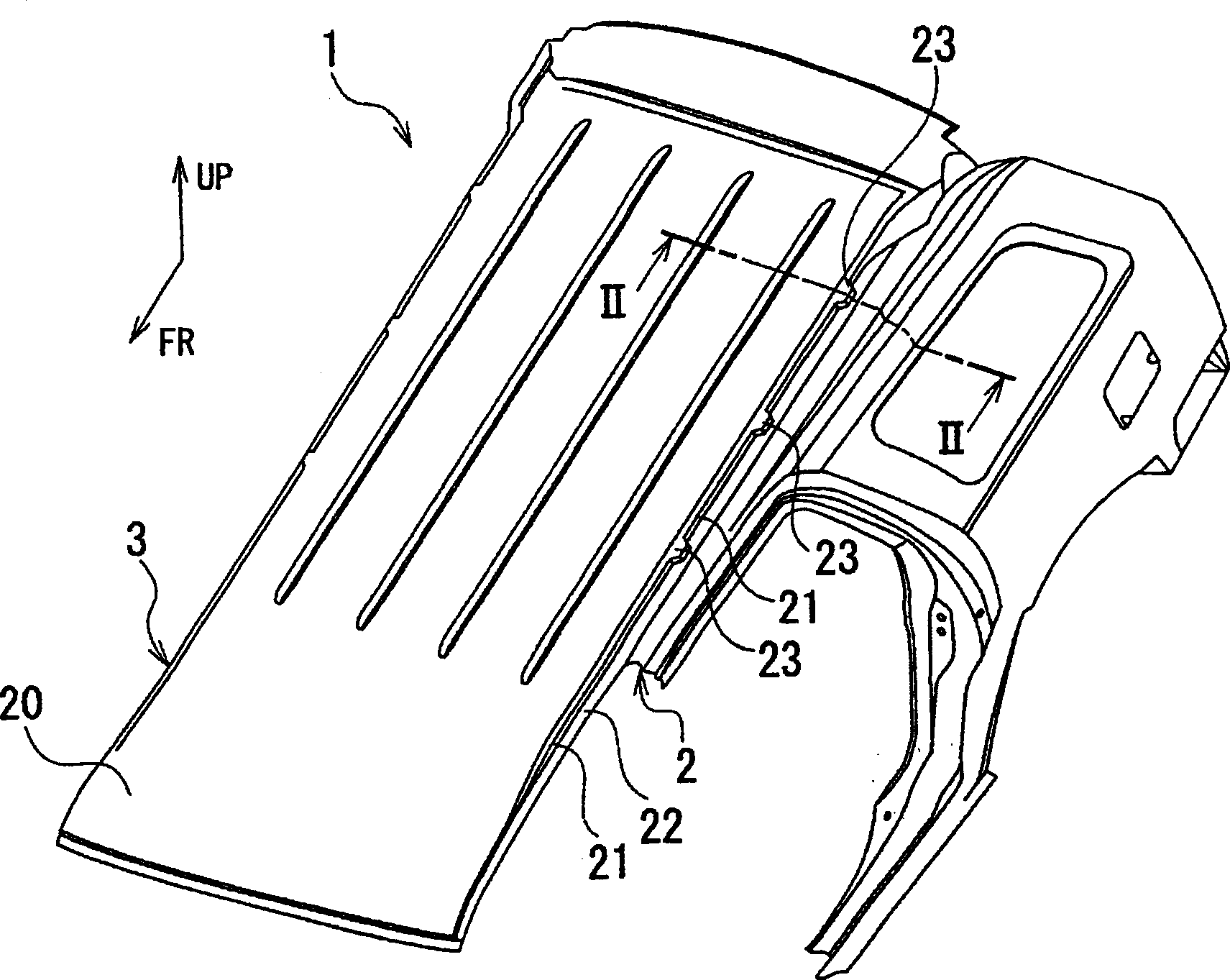

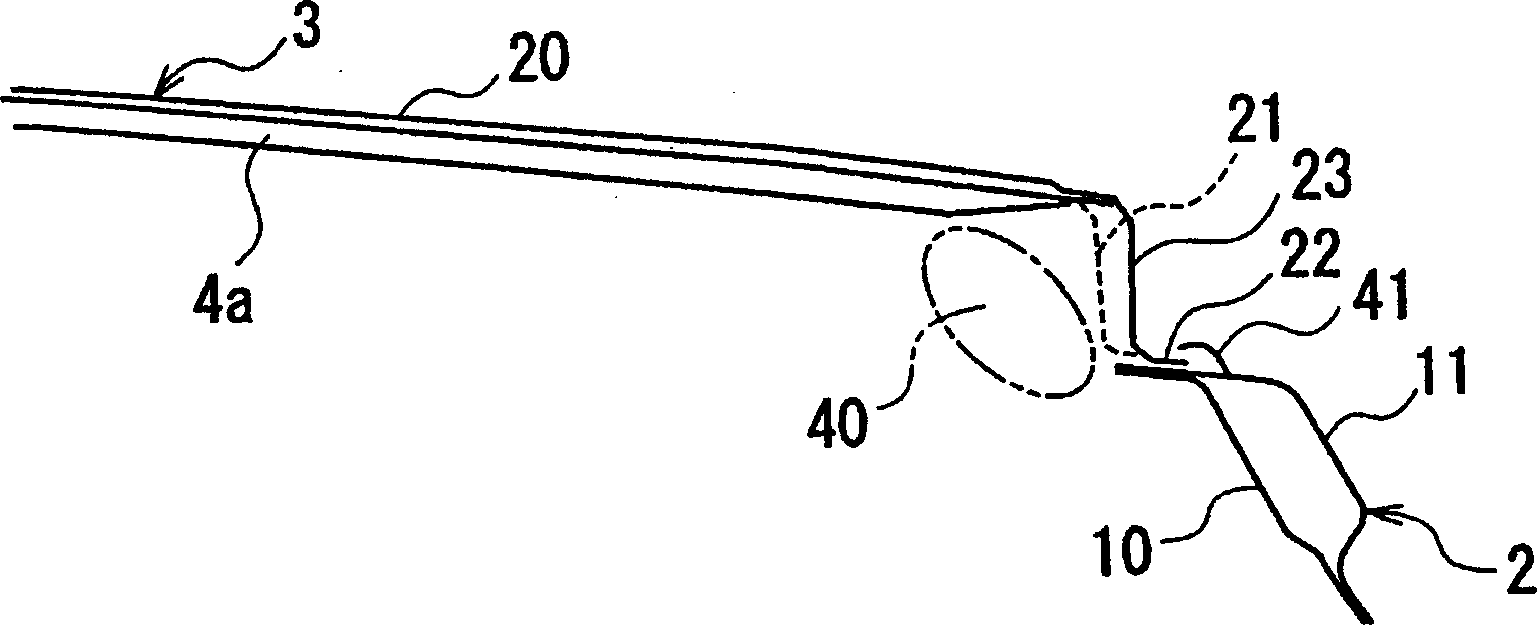

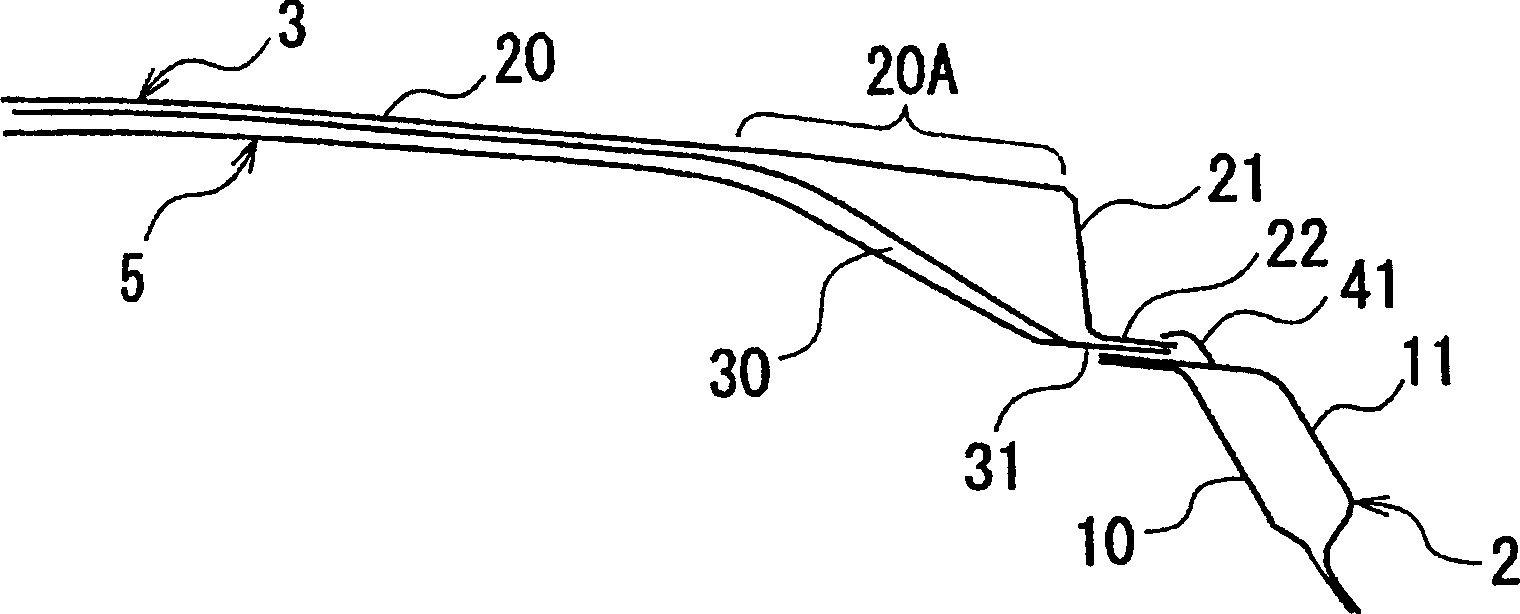

[0023] Next, an embodiment of the present invention will be described with reference to the accompanying drawings. figure 1 In order to show the perspective view of the state where the side roof rail and the roof panel are joined in this embodiment, figure 2 for figure 1 Section view of II-II view, image 3 It is an enlarged cross-sectional view of the main part of the top cover structure of the comparative example, Figure 4 for figure 1 An enlarged perspective view of the main part of the ceiling wall of Figure 5 To show the roof arches are configured in figure 1 An enlarged top view of the main part of the state on the top plate. In addition, FR and UP in the figure represent the front of the vehicle and the upper side of the vehicle, respectively.

[0024] like figure 1 and figure 2 As shown, the vehicle 1 of this embodiment has: side roof rails 2 extending in the vehicle front-rear direction on both sides of the vehicle width direction, a roof panel 3 placed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com