Planer with improved chip removal

A technology of planer and shavings, which is applied in the field of shaving discharge channels, and can solve problems such as shavings falling off, blocking observation of workpieces, and blocking channels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

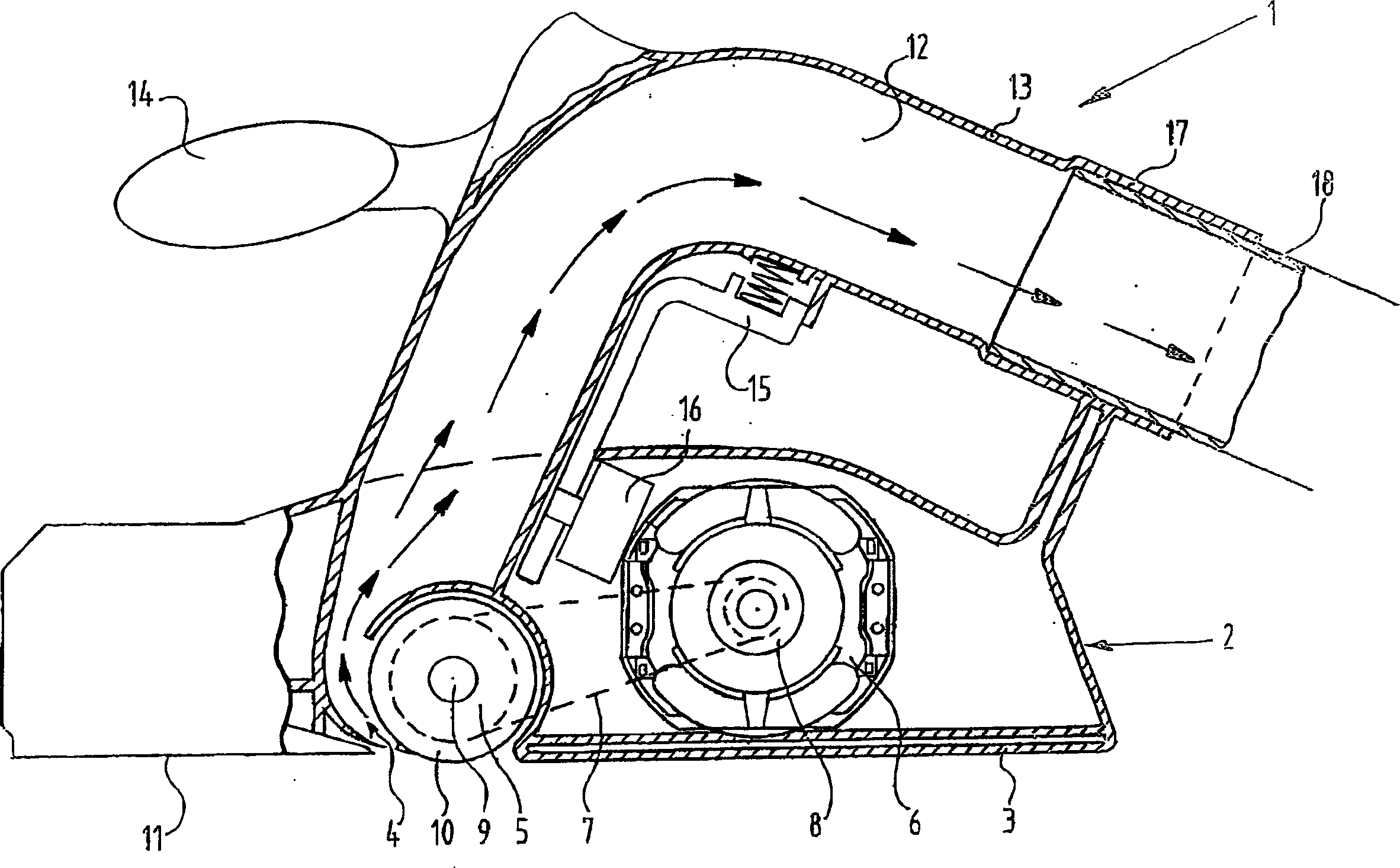

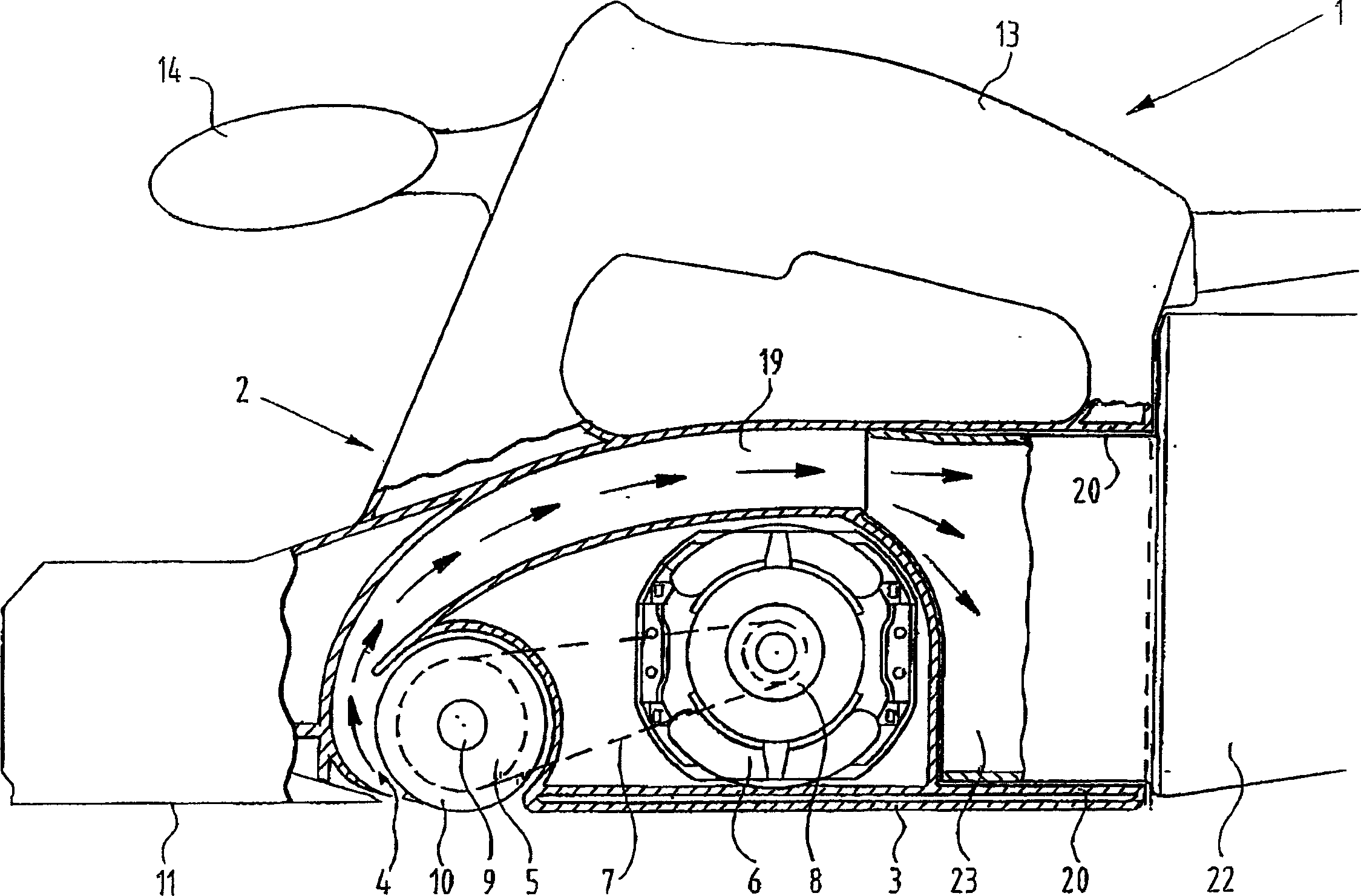

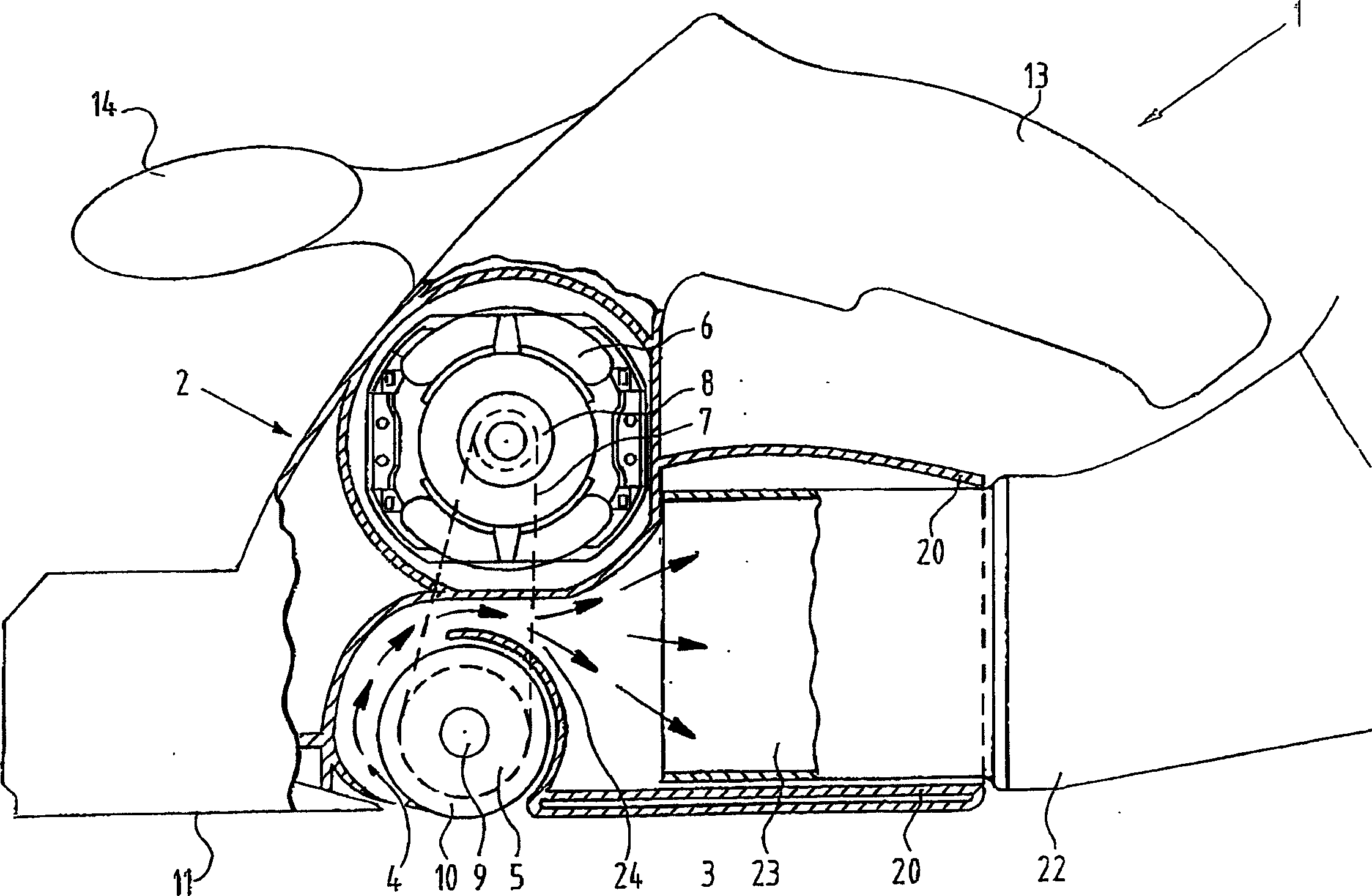

[0019] figure 1 The longitudinal cross-sectional form of the planer as a whole indicated by reference numeral 1 is shown. The planer includes a housing 2 provided with a base plate 3. At the front of the substrate in the moving direction, the planer knife roll cavity 4 provided with the planer knife roll 5 is recessed into the housing. The planer knife roll 5 is mounted via a shaft 9 supported by a bearing not shown in the figure. The planer knife roller holder is driven by an electric motor 6 arranged in the housing via a toothed belt 7 which surrounds a pulley 8 arranged on the motor shaft and a pulley 10 arranged on the planer knife roller shaft.

[0020] The adjustable base 11 is provided at the front of the housing. The mechanism for adjusting the base is not shown because it is not important to the invention.

[0021] The above-mentioned elements can be found in planers of the prior art.

[0022] The present invention provides an arrangement in which the shavings discharge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com