Formula of milk beer and making process

A milk beer and formula technology, applied in beer brewing and other directions, can solve the problem of high cost of small-scale production, and achieve the effects of rich foam, milky white color and sweet taste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

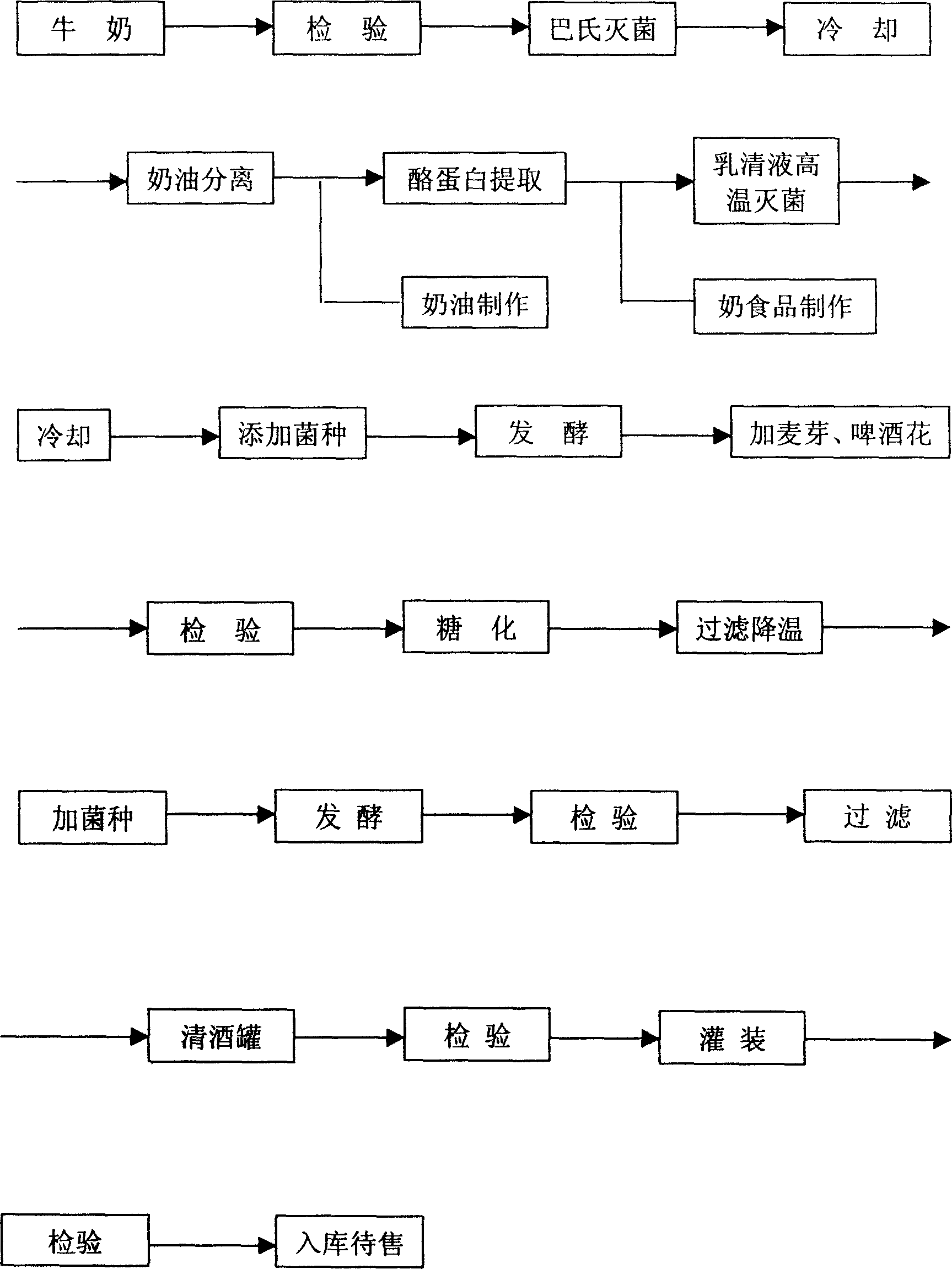

Method used

Image

Examples

example 1

[0037] Produce 100Kg milk beer

[0038] Formula: 100Kg of milk is extracted from fat and protein, 88.5Kg of left whey is extracted, 0.5Kg of compound flora such as Bifidobacterium, Kluyveromyces, Saccharomyces cerevisiae, and Candida lactis, 10Kg of malt, 0.5Kg of hops, beer Yeast 0.5Kg.

[0039] crafting process:

[0040] The milk that has passed the inspection is put into a pasteurization tank and sterilized at 75°C for 30 minutes, then cooled to 38°C for cream separation, and the casein is removed from the milk, leaving 88.5Kg of whey, and cooled to 135°C for 7 minutes. 36°C, add Bifidobacterium, Kluyveromyces, Saccharomyces cerevisiae, Candida lactis and other complex flora, control the fermentation temperature between 32--36°C, ferment for 7 days, add the fermented whey liquid 10Kg malt, 0.5Kg hop saccharification (saccharification is operated according to the ordinary beer process), the degree of saccharification wort is 10°, filtered and cooled to 9°C, put into the fe...

example 2

[0042] Production of 100Kg nutritionally enhanced milk beer

[0043] Formula: 10Kg of whey powder, 73.5Kg of water, 10Kg of malt, 0.5Kg of hops, 0.5Kg of compound flora such as bifidobacterium, Kluyveromyces, and Candida lactis, 0.5Kg of beer yeast, and 5Kg of defatted powder.

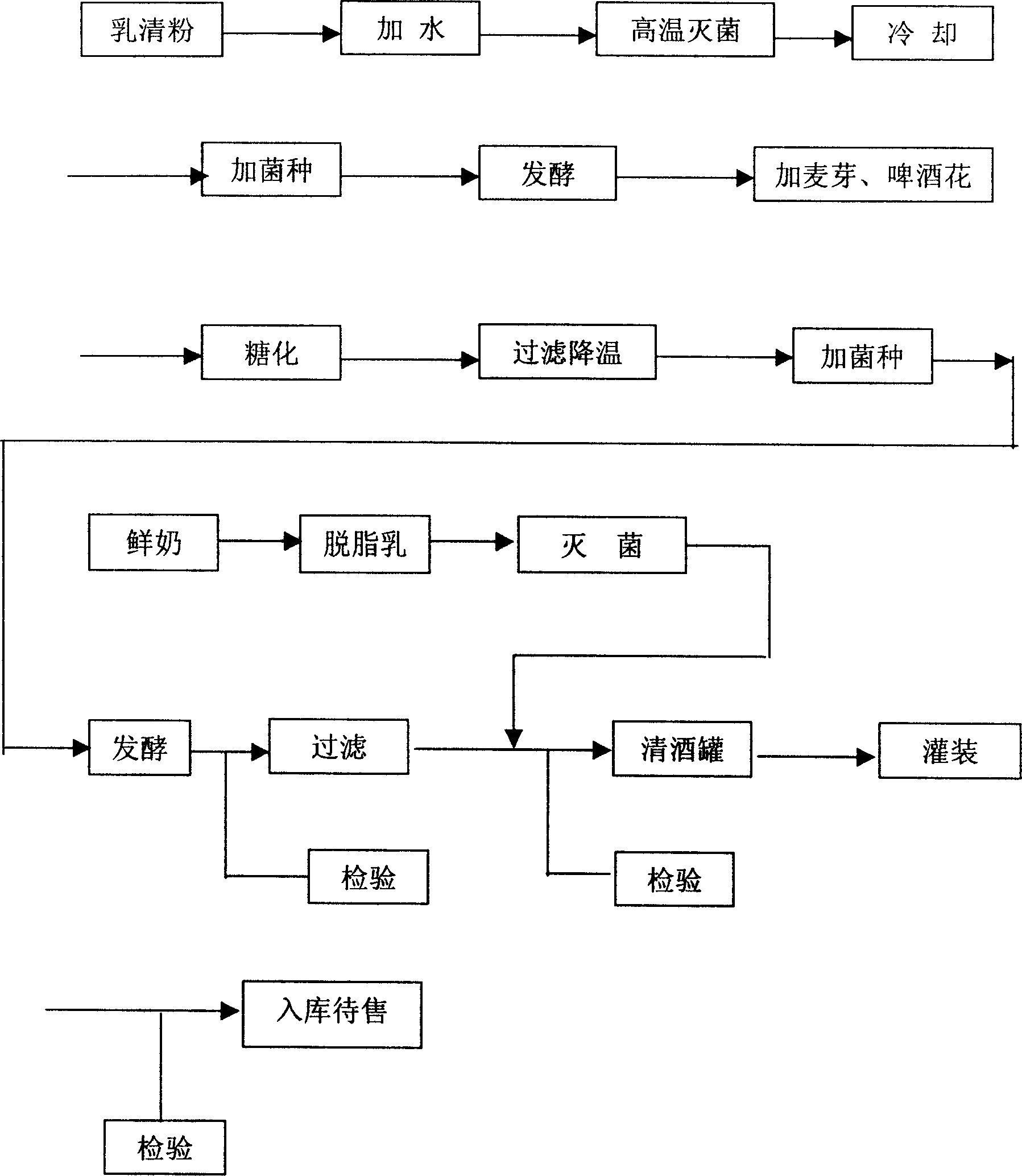

[0044] crafting process:

[0045] Dissolve 10Kg of whey powder in water (purified water), sterilize at 75°C for 30 minutes after melting, cool down to 36°C, pour into a fermenter and add 0.5Kg of complex flora, ferment for 3-7 days, add fermented whey liquid to 10Kg Malt, 0.5Kg hop saccharification (saccharification is operated according to the ordinary beer process), the degree of saccharification wort is 10°, filtered and cooled to 9°C, poured into the fermenter and added with 0.5Kg of beer yeast for fermentation, during the 20-day fermentation process, it is operated according to the ordinary beer process , Mix sterilized skim milk or skim powder reduced milk into the sake tank. Put the fermented ...

example 3

[0047] Formula for producing 100Kg milk beer

[0048] Whey liquid 90.5Kg, malt 8Kg, hops 0.5Kg, Max varietal yeast, lactose red yeast compound flora 0.5Kg, beer yeast 0.5Kg.

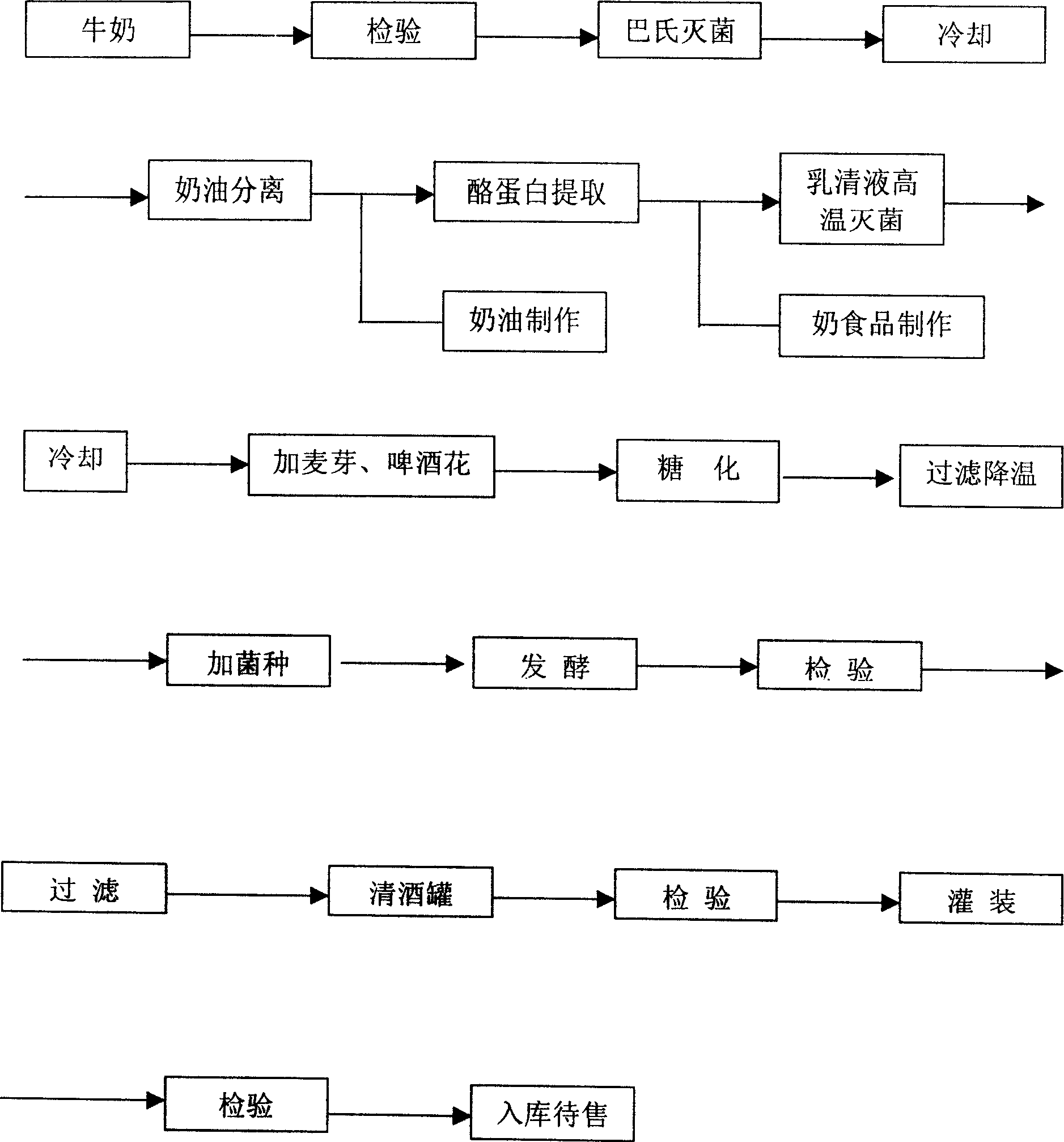

[0049] crafting process:

[0050] Pasteurize the inspected milk, lower the temperature to 36°C--40°C, separate the cream and extract the casein; sterilize the whey at 100--135°C; sterilize the whey at 100°C for 15 minutes After sterilization, add 8Kg of malt and 0.5Kg of hops for saccharification. The saccharification is operated according to the ordinary beer process, the degree of saccharification wort is 8°, filtered and cooled to 9°C, put into the fermenter, add 0.5Kg of beer yeast for fermentation, and add kefir complex bacteria Group 0.5Kg. During the 20-day fermentation process, it was operated according to the ordinary beer process. The fermented milk beer was poured into the sake tank and kept for 24 hours. At 0°C-3°C, the carbon dioxide pressure was 1.2Kg and filled in the bottle. After testi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com