Colloidal electrolyte of lead acid accumulator

A technology of colloidal electrolyte and lead-acid batteries, which is applied in the direction of lead-acid batteries, etc., can solve the problems of unsuitable batteries, decreased discharge performance, and easy cracking, and achieve the effects of preventing precipitation, maintaining moisture, and ensuring consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0010] Embodiment 1 A kind of lead-acid storage battery colloidal electrolyte each component counts as follows by percentage:

[0011] Nanoscale silicon dioxide (SiO 2 ) 0.2%

[0012] Sodium Carboxymethyl Cellulose (CMC) 0.3%

[0013] Stannous Sulfate (SnSO 4 ) 0.5%

[0014] Sulfuric acid (H 2 SO 4 ) 40%

[0015] Water 59%

Embodiment 2

[0016] Embodiment 2 A kind of lead-acid storage battery colloidal electrolyte each component counts as follows by percentage:

[0017] Nanoscale silicon dioxide (SiO 2 ) 0.4%

[0018] Sodium Carboxymethyl Cellulose (CMC) 0.1%

[0019] Stannous Sulfate (SnSO 4 ) 0.6%

[0020] Sulfuric acid (H 2 SO 4 ) 35%

[0021] Water 63.9%

Embodiment 3

[0022] Embodiment 3 A kind of lead-acid storage battery colloidal electrolyte each component counts as follows by percentage:

[0023] Nanoscale silicon dioxide (SiO 2 ) 0.5%

[0024] Sodium Carboxymethyl Cellulose (CMC) 0.2%

[0025] Stannous Sulfate (SnSO 4 ) O.2%

[0026] Sulfuric acid (H 2 SO 4 ) 45%

[0027] Water 54.1%

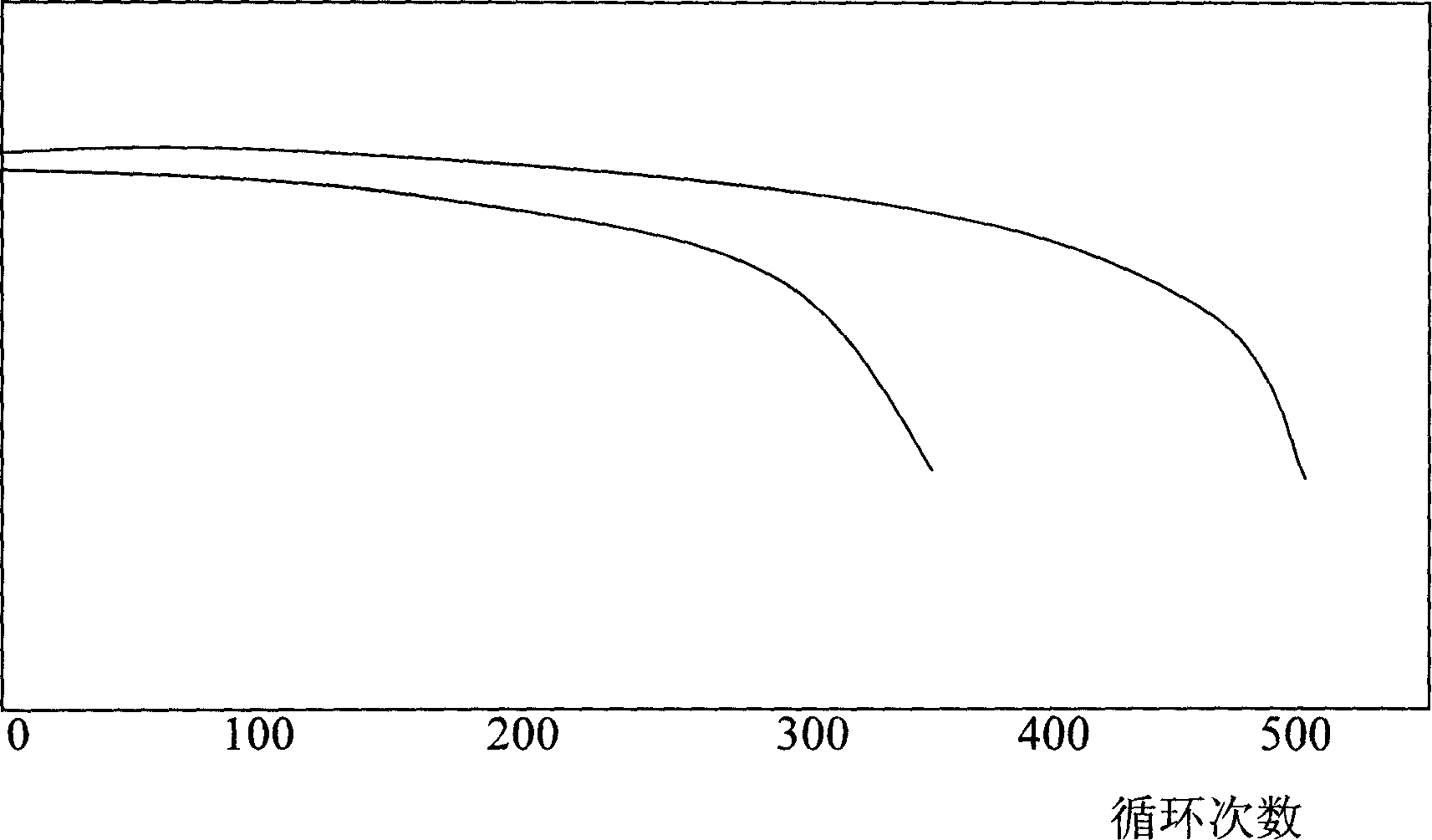

[0028] From attached figure 1 It can be seen from the comparison chart and table 1 and table 2 of battery life of colloidal electrolyte and ordinary electrolyte battery that the present invention improves the charging acceptance capacity, also improves the battery capacity, ensures the consistency of the battery, reduces water loss, and protects the pole plate, which can greatly improve The cycle life of the battery.

[0029] A (blank)

[0030] A (blank)

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com