Tunnelling resonance microsound sensor

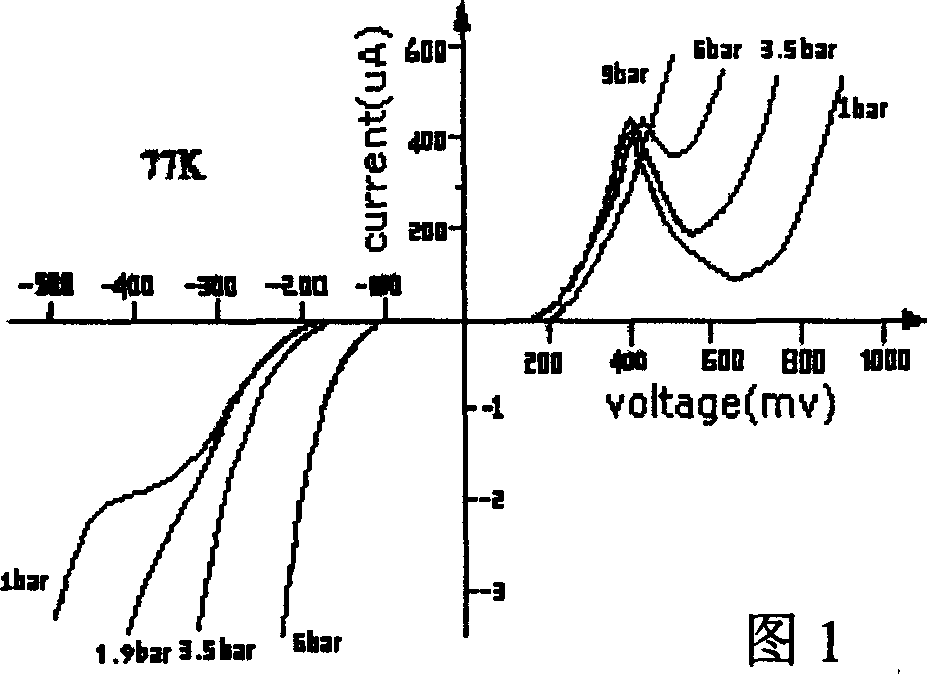

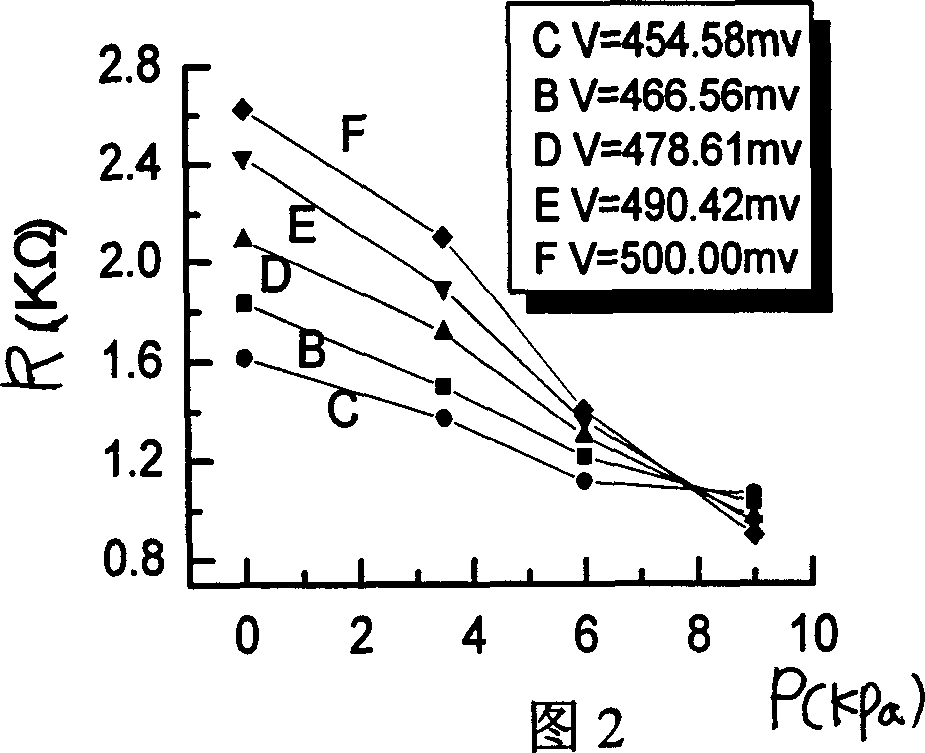

An acoustic sensor and resonance tunneling technology, applied in the sensor field, can solve the problems of inability to meet high-precision requirements, low sensitivity, poor temperature stability, etc., and achieve the effects of low cost, good temperature stability, and improved sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

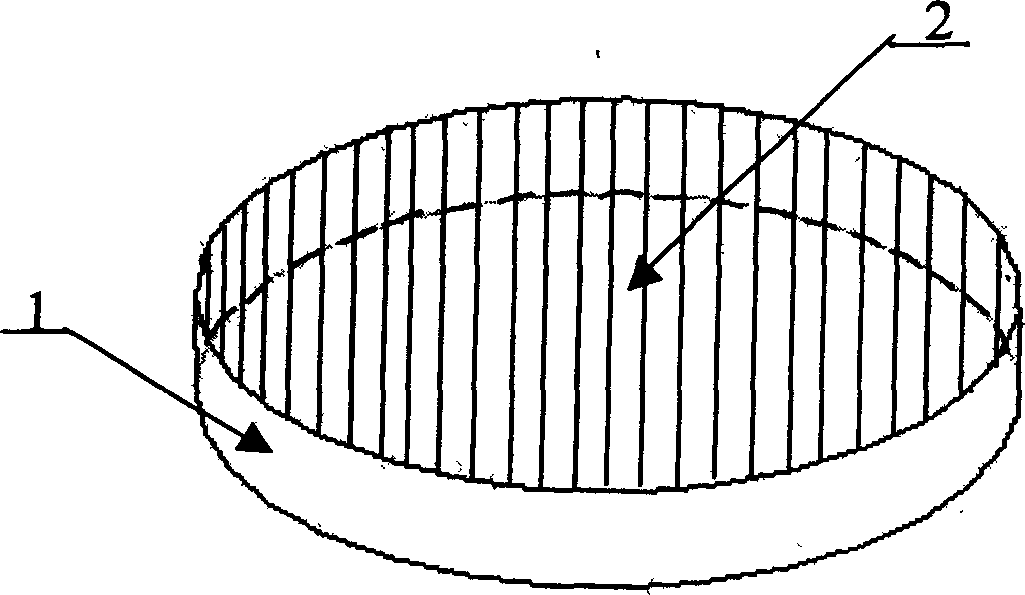

[0031] The resonant tunneling microacoustic sensor is made by the following method: the required superlattice film 2 is grown on the semiconductor substrate 1 by molecular beam epitaxy (MBE) technology, and the microelectromechanical device (MEMS) processing technology is used to Do the following processing:

[0032](1) Utilize the etching process to remove all the thin films on the substrate 1 except the four thin films distributed in the shape of "ten" (such as Figure 4 as shown in a);

[0033] (2) Using an etching process, each remaining film ( Figure 4 b) The rest of the area except the strip area is etched to the electrode contact layer 3 of the collector, so that a convex line is formed on each film ( Figure 4 c);

[0034] (3) Deposit the ohmic contact layer on the surface of the film by the deposition method, and then use the lift-off method to make the collector electrode 4 and the emitter electrode 7 ( Figure 4 d) (The emitter does not need to be stripped); th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com