Lining thickness detector of smelting furnace

A metallurgical furnace and thickness detection technology, applied in electromagnetic measuring devices, electric/magnetic thickness measurement, etc., can solve problems such as being susceptible to interference, troublesome furnace construction, and malfunction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

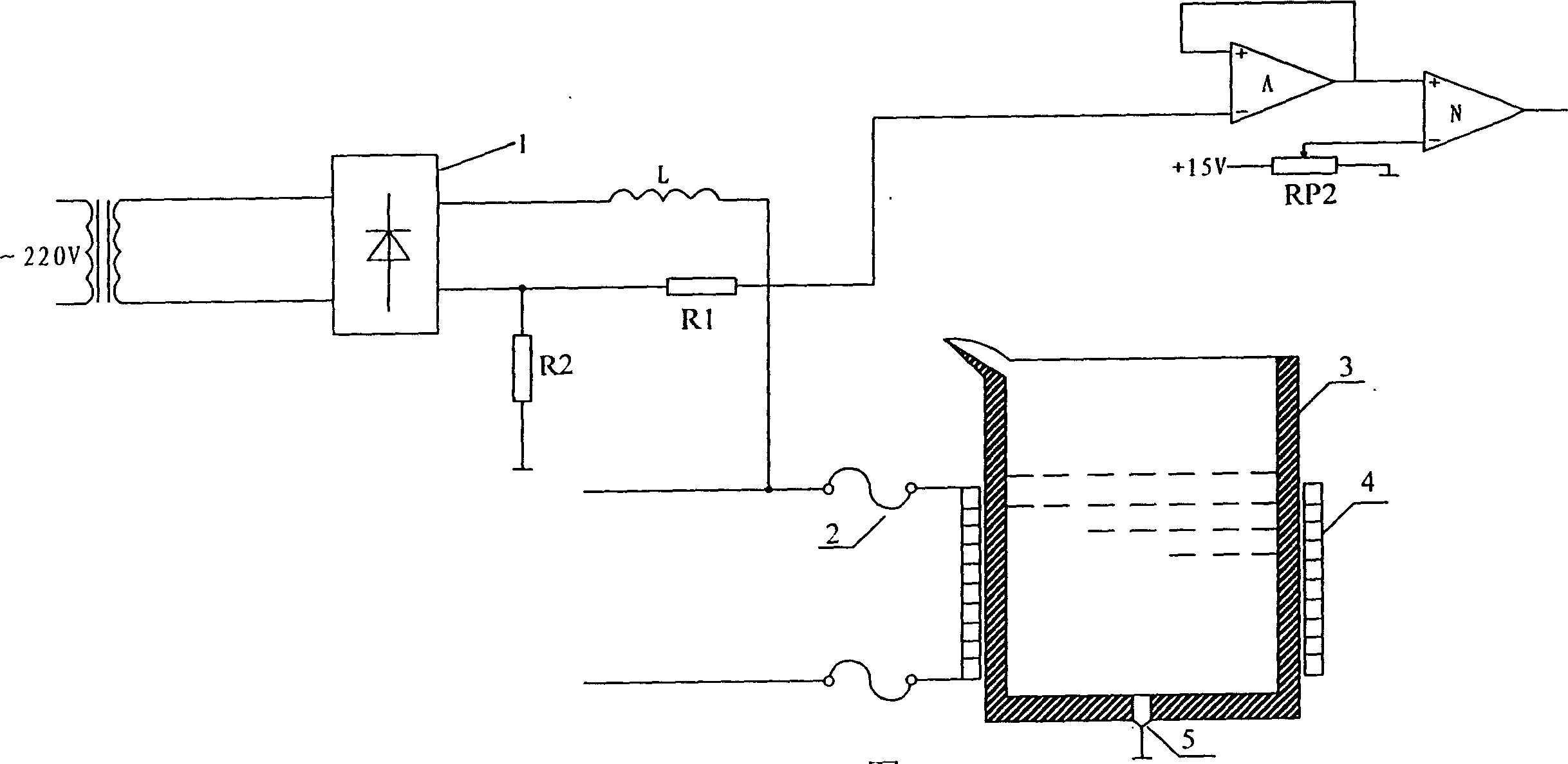

[0006] Referring to the accompanying drawings, its structure is that the output end of the rectifier bridge 1 outputting low-voltage DC voltage is directly connected to the induction coil 4 through the choke inductance L, and the other output end of the rectifier bridge 1 is connected to the furnace bottom electrode 5 through the resistor R2.

[0007] When working, the external power supply is stepped down by a transformer, rectified by a rectifier bridge, and the rectifier bridge outputs a low-voltage DC voltage to be added between the induction coil 4 and the furnace bottom electrode 5 . One end of the rectifier bridge output low-voltage DC voltage is directly connected to the induction coil 4 through the choke inductance L. The other end is connected to the furnace bottom electrode 5 through a resistor R2. When the furnace lining is normal, the current passing through the resistor R2 is very small, and the divided voltage on the resistor R2 is also very small. At this time,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com